Preparation method of shoe upper fabric

A technology for shoe uppers and fabrics, applied in the field of textile fabrics, can solve problems such as poor air permeability and damage to mechanical properties, and achieve the effects of low cost, good dimensional stability, and good air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A preparation method for shoe upper fabric, the steps are as follows:

[0039] (1) Preparation of self-curling elastic yarn:

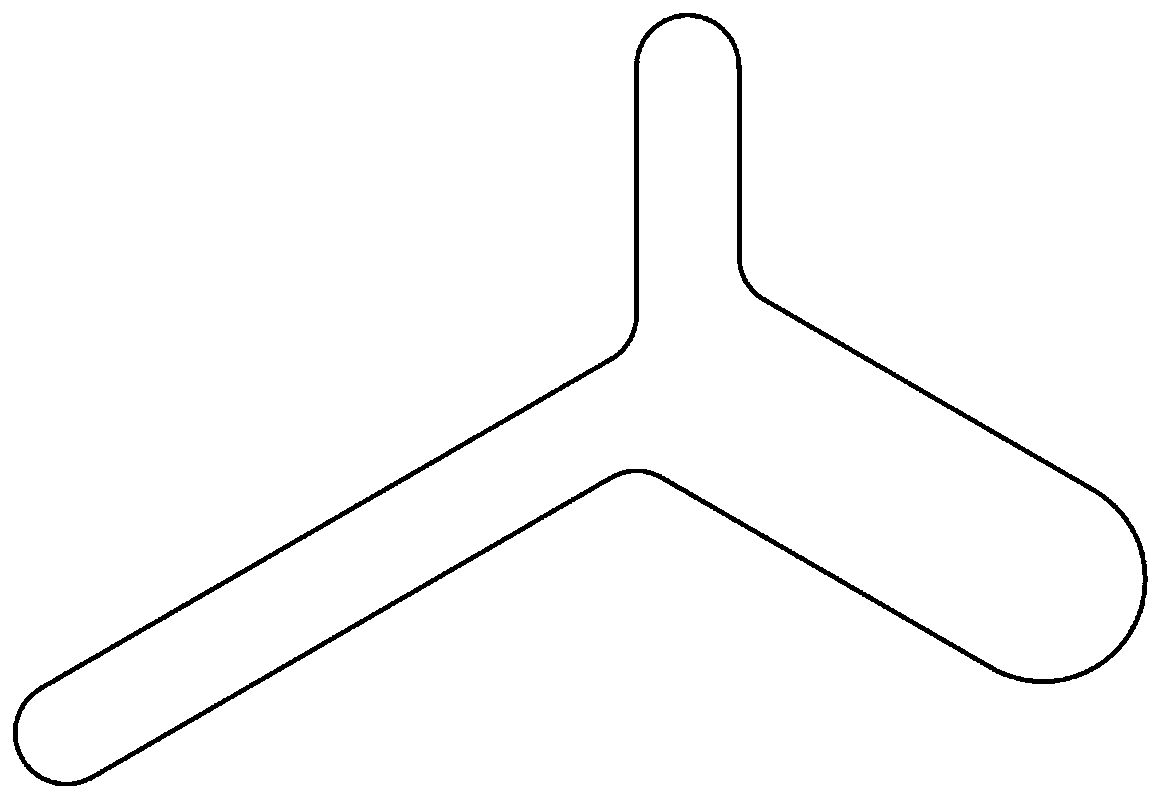

[0040] Extrude the PBT melt with an intrinsic viscosity of 1.1dL / g from the three-lobed spinneret hole on the spinneret and cool it with a ring blower. FDY filaments are obtained according to the FDY process, and then self-curling elastic filaments are obtained through relaxation heat treatment. ;

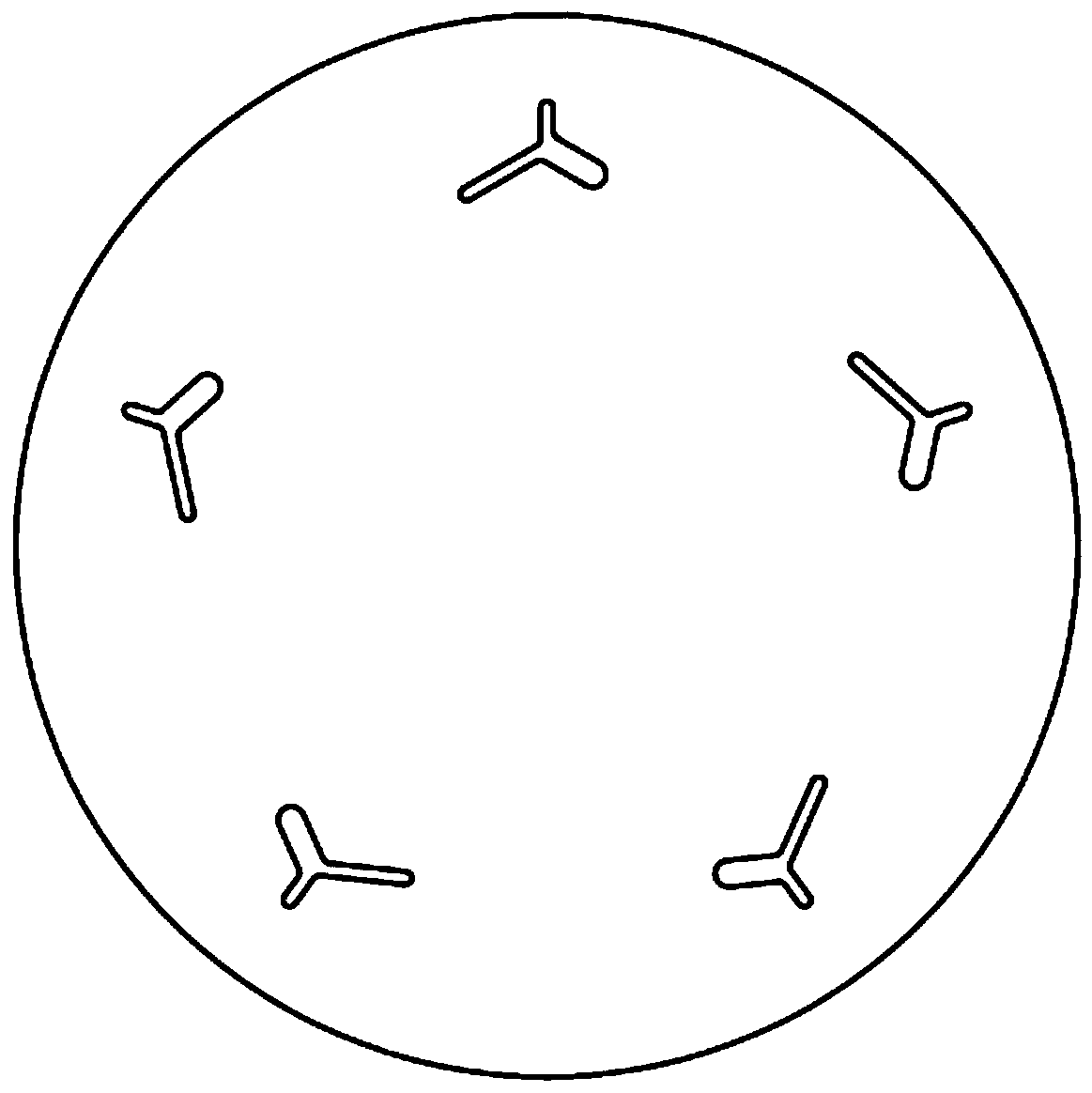

[0041]The ratio of the length of the three lobes of the same three-lobed spinneret hole is 1.0:1.1:2.5, the ratio of the corresponding width of the three lobes is 1:1.6:1, the ratio of the length and width of the shortest lobe is 3.5:1, adjacent The angle between the centerlines of the two lobes is 120°; the shape and size of the three lobes of different three-lobed spinneret holes are the same; there is a circle of equidistantly distributed three-lobed spinneret holes on the spinneret plate, and the number is 24 One, the pointing direction of the ...

Embodiment 2

[0050] A preparation method for a shoe upper fabric, the steps are as follows:

[0051] (1) Preparation of self-curling elastic yarn:

[0052] Extrude the PBT melt with an intrinsic viscosity of 1.1dL / g from the three-lobed spinneret hole on the spinneret and cool it with a ring blower. FDY filaments are obtained according to the FDY process, and then self-curling elastic filaments are obtained through relaxation heat treatment. ;

[0053] The ratio of the length of the three lobes of the same three-lobed spinneret hole is 1.0:1.1:2.5, the ratio of the corresponding width of the three lobes is 1:1.8:1, and the ratio of the length and width of the shortest lobe is 3.5:1, adjacent The angle between the center lines of the two leaves is 120°; the spinneret plate is provided with a circle of equidistantly distributed trilobal spinneret holes, the number is 24, and the direction of leaf I of one of the trilobal spinneret holes is Deviate from the center of the circle by 12°, take...

Embodiment 3

[0062] A preparation method for a shoe upper fabric, the steps are as follows:

[0063] (1) Preparation of self-curling elastic yarn:

[0064] Extrude the PBT melt with an intrinsic viscosity of 1.15dL / g from the three-lobed spinneret hole on the spinneret and cool it with a ring blower. FDY filaments are produced according to the FDY process, and then self-curling elastic filaments are obtained through relaxation heat treatment. ;

[0065] The ratio of the length of the three lobes of the same three-lobed spinneret hole is 1.0:1.2:2.5, the ratio of the corresponding width of the three lobes is 1:1.9:1, the ratio of the length and width of the shortest lobe is 3.9:1, adjacent The angle between the centerlines of the two lobes is 120°; the shape and size of the three lobes of different three-lobed spinneret holes are the same; there is a circle of equidistantly distributed three-lobed spinneret holes on the spinneret plate, and the number is 24 One, the pointing direction of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Intrinsic viscosity | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

| Total fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com