Control method and device of heat pump system, clothes dryer, storage medium and processor

A control method and technology of a heat pump system, applied in the fields of clothes dryers, devices, control methods of heat pump systems, storage media and processors, can solve the problems of low drying efficiency and high compressor failure rate, and improve drying efficiency , Reduce the failure rate and increase the effect of high frequency running time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

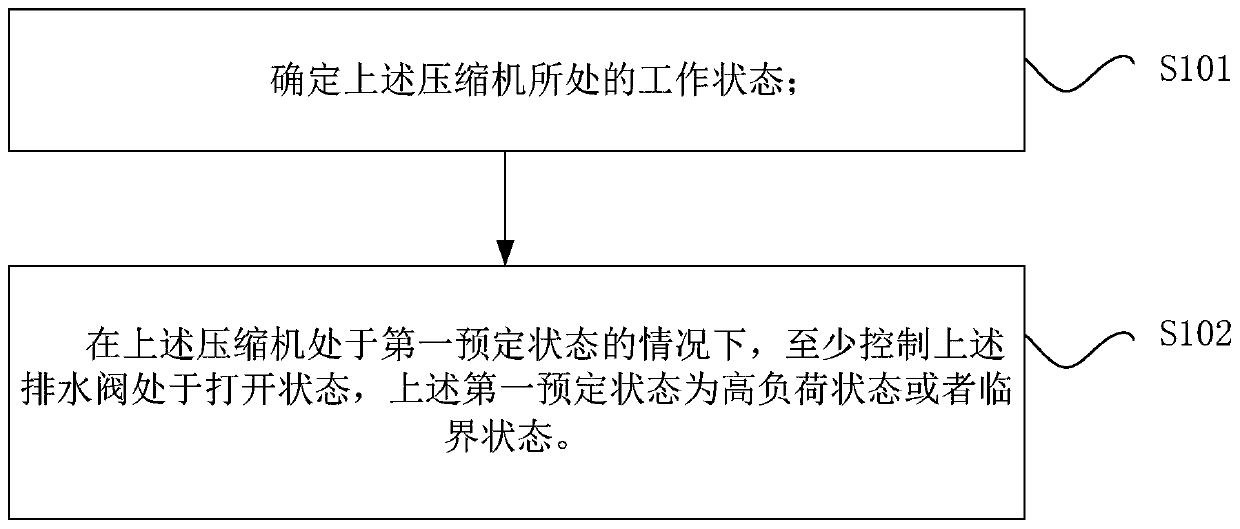

[0079] This embodiment relates to a specific control method for a heat pump system, which includes:

[0080] The difference between the cold temperature T1 and the drying temperature T2 is selected as the criterion for determining whether the compressor is overloaded:

[0081] The drying temperature refers to the temperature at which the inlet air temperature is kept constant by the compressor up and down frequency when the heat pump dryer is working stably. Select ΔT=T1-T2=10 as the limit value for judging the compressor load.

[0082] Preferably, in order to increase the high-frequency operation time of the compressor, the control method for degrading the overload of the compressor is divided into two steps: the first step, the drain valve is normally open; the second step, the drain valve is normally open and the frequency is reduced. If the first step fails to degrade the compressor load, proceed to the second step.

[0083] In the first step, when 13°C≥△T>10°C, the comp...

Embodiment 2

[0091] Select the rated power of the compressor as the criterion for judging whether the compressor is overloaded:

[0092]First, determine the ambient temperature. According to the different ambient temperatures, different compressor power values are selected as the criteria for judging that the compressor reaches high load. The ambient temperature is determined according to the temperature of the drum outlet, and the ambient temperature is roughly divided into three ranges: low temperature environment 0-15°C, medium temperature environment 16-30°C, high temperature environment 31-43°C;

[0093] The state of the compressor is determined by using the relationship between the compressor power P and the compressor rated power Pe.

[0094] In low temperature environment, if 0.95Pe≥P≥0.9Pe, the compressor is under high load; if Pe>P>0.95Pe, the compressor is in a critical state; if P≥Pe, the compressor is under overload; The stages are different, and run according to the corres...

Embodiment 3

[0099] This embodiment relates to a specific drying control method of a clothes dryer, which includes the following steps:

[0100] a. Drying starts;

[0101] b. Judging the temperature inside the barrel according to the temperature of the air out of the drum.

[0102] c. According to the judgment result, set the target frequency value and the protection limit value when the overload is degraded;

[0103] d. Run the compressor frequency increase program, whether the compressor is overloaded or not during the frequency increase process; if yes, go to step f; if not, go to step g;

[0104] f. Compressor overload degradation program; after the operation, whether the compressor is overloaded; if yes, stop; if not, go to step h;

[0105] g. Whether the compressor meets the frequency reduction program conditions; if yes, go to step h; if not, go to step d;

[0106] h. The compressor runs the frequency reduction control program; whether the compressor is overloaded or not during t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com