Construction method for connecting point of sleeve-connected tunnel connector of open and underground excavated structure

A construction method and connection point technology, which can be applied to infrastructure engineering, underwater structures, artificial islands, etc., can solve problems such as poor integrity of underground excavation structures, difficulties in waterproof construction, and complicated construction procedures, and achieve strong integrity and improved Structural shear resistance, improve the effect of waterproof effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

[0037] The present invention will be described in detail below with reference to the accompanying drawings and examples.

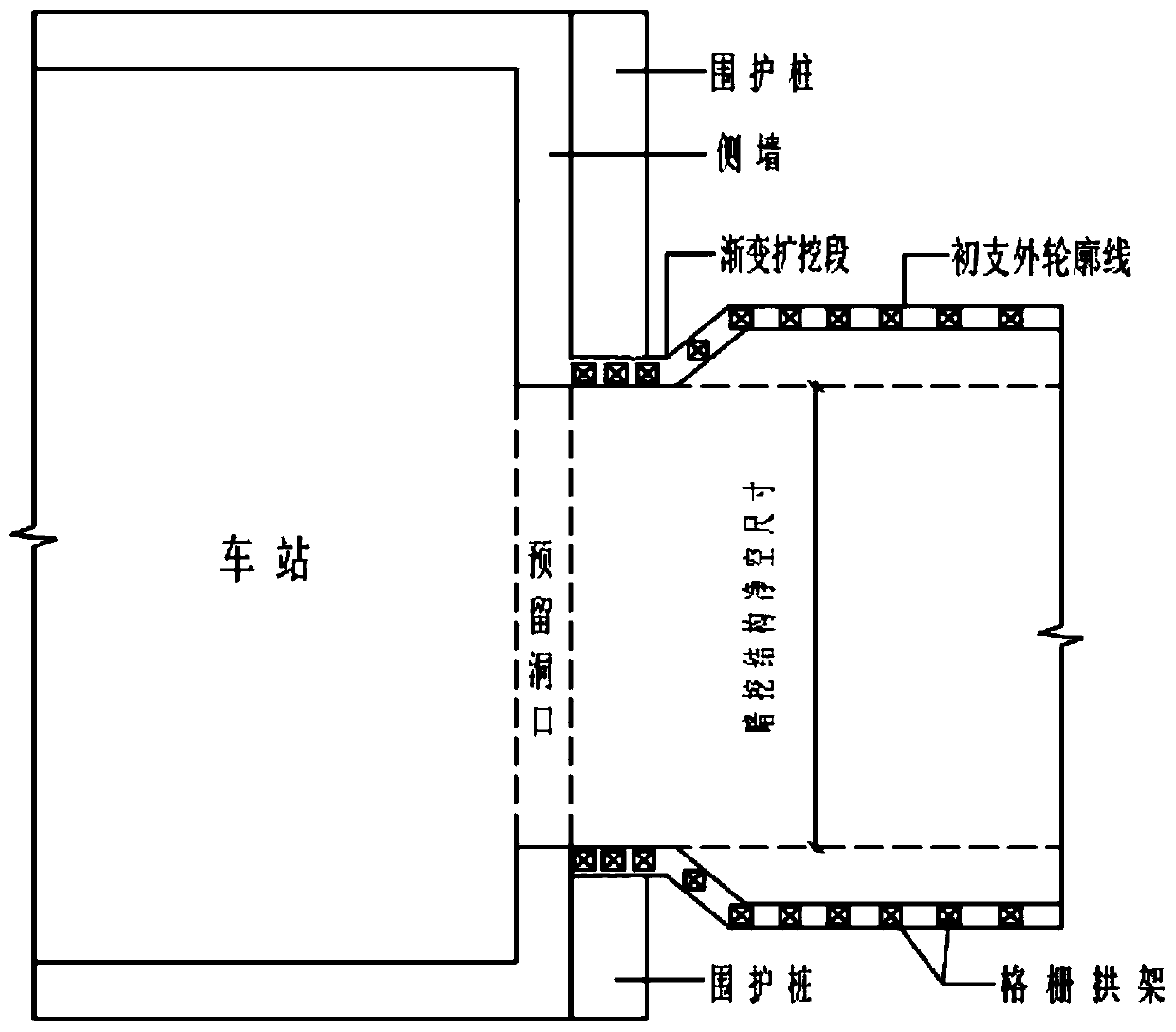

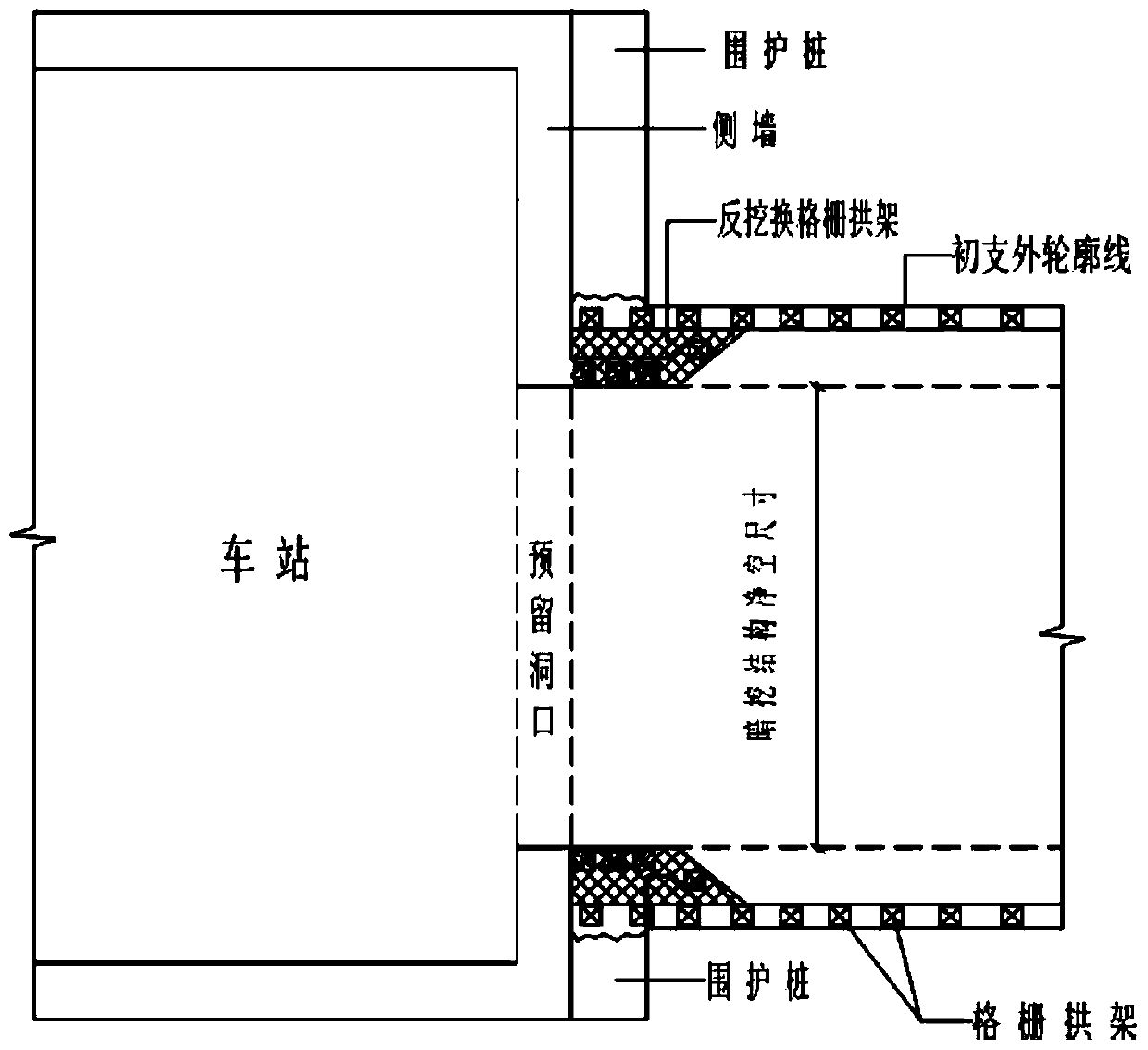

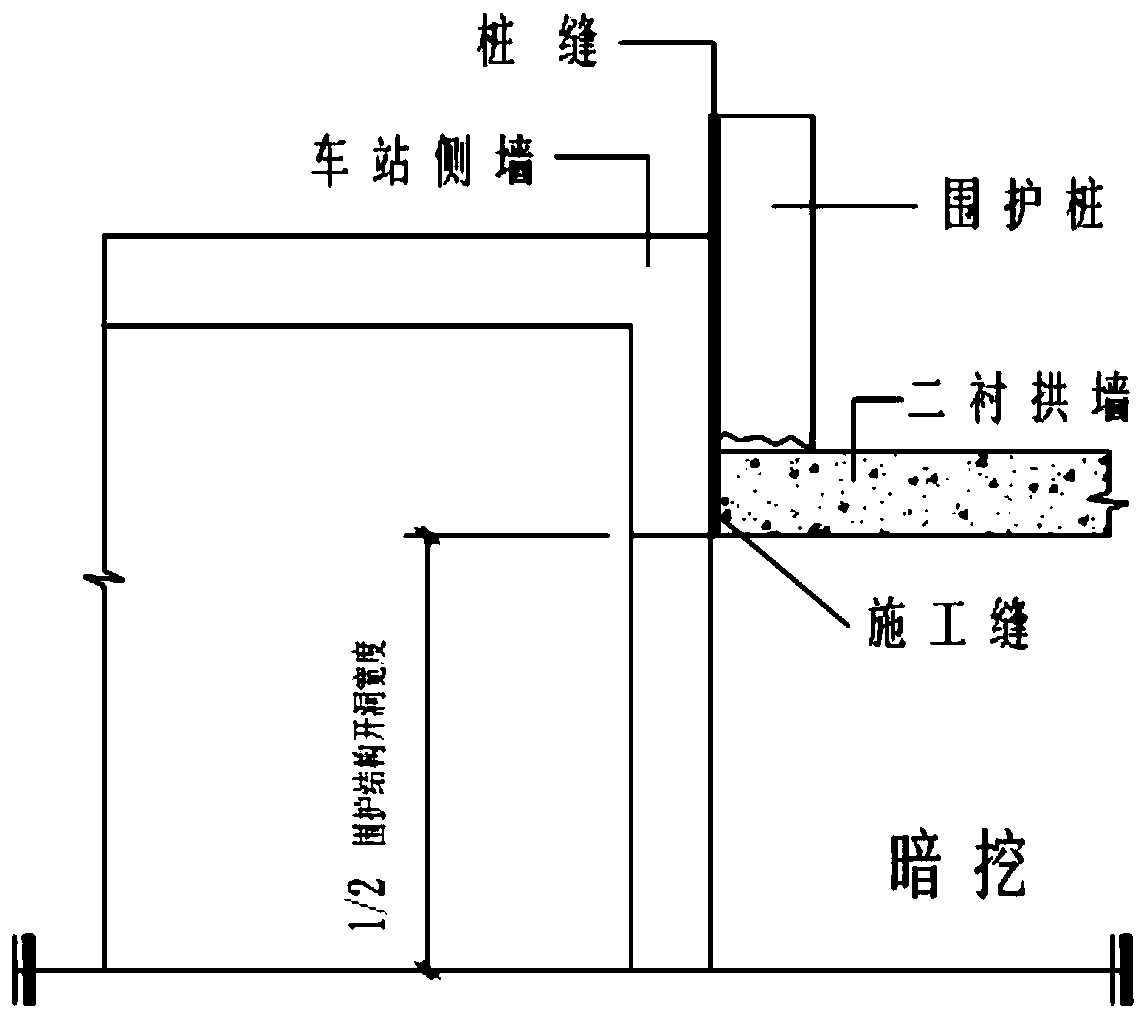

[0038] Such as Figure 1-Figure 3 As shown, the existing construction method for the interface of the open and concealed excavation structure of the subway station comprises the following steps: S1, the opening is reserved: the construction of the open and concealed station structure is completed, and the section is reserved for underground excavation on the end wall, and the entrance and exit The hole interface, the size of the hole reserved on the side wall of the station is the clearance size of the secondary lining structure of the underground excavation; In order to ensure the safety of the hole construction, the hole must be quickly closed into a ring after the retaining pile is b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com