Composite electromagnetic type dynamic vibration absorber

A dynamic vibration absorber and composite electromagnetic technology, which is applied in the field of vibration absorption, can solve the problems that the output force density and output force linearity cannot be taken into account.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

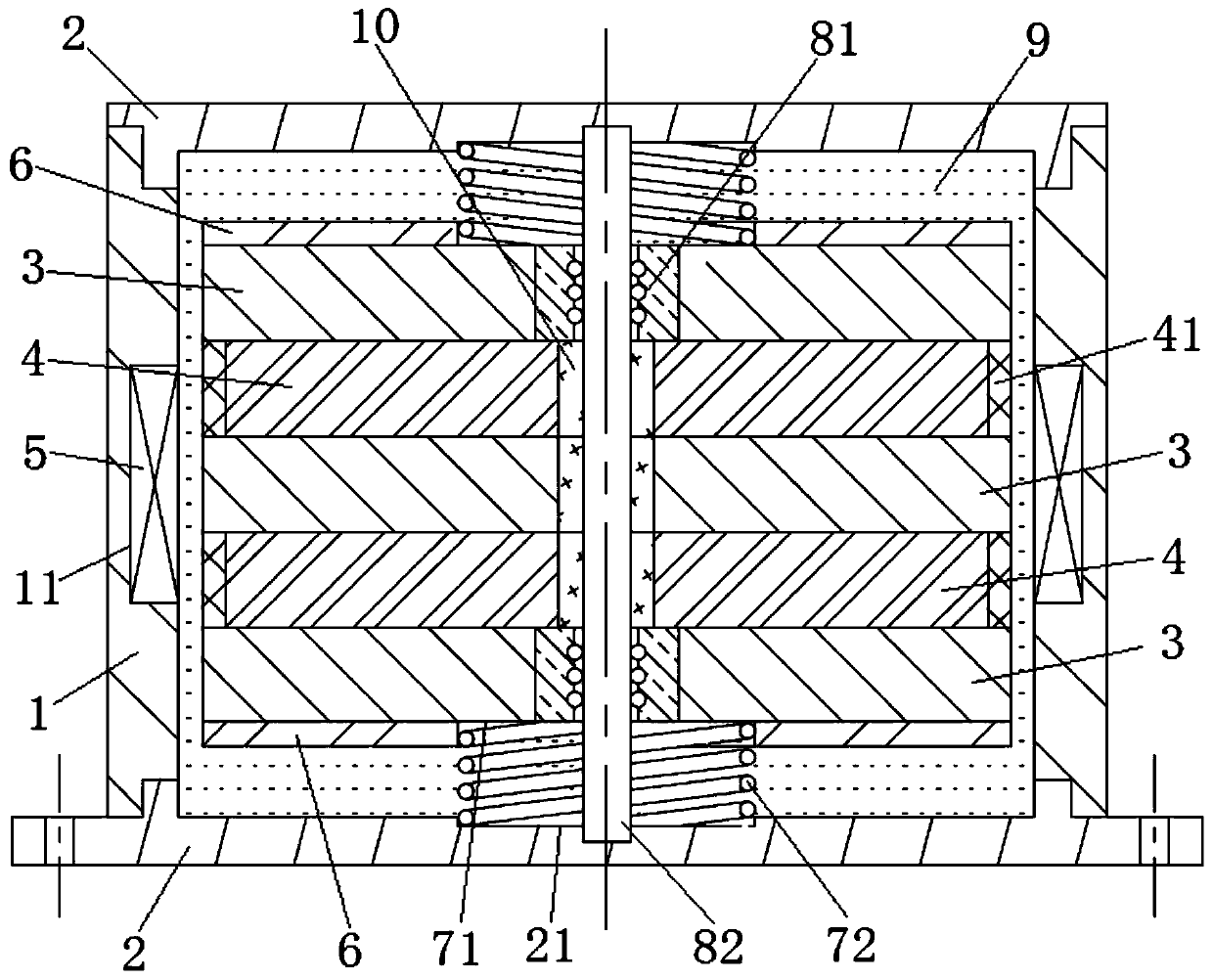

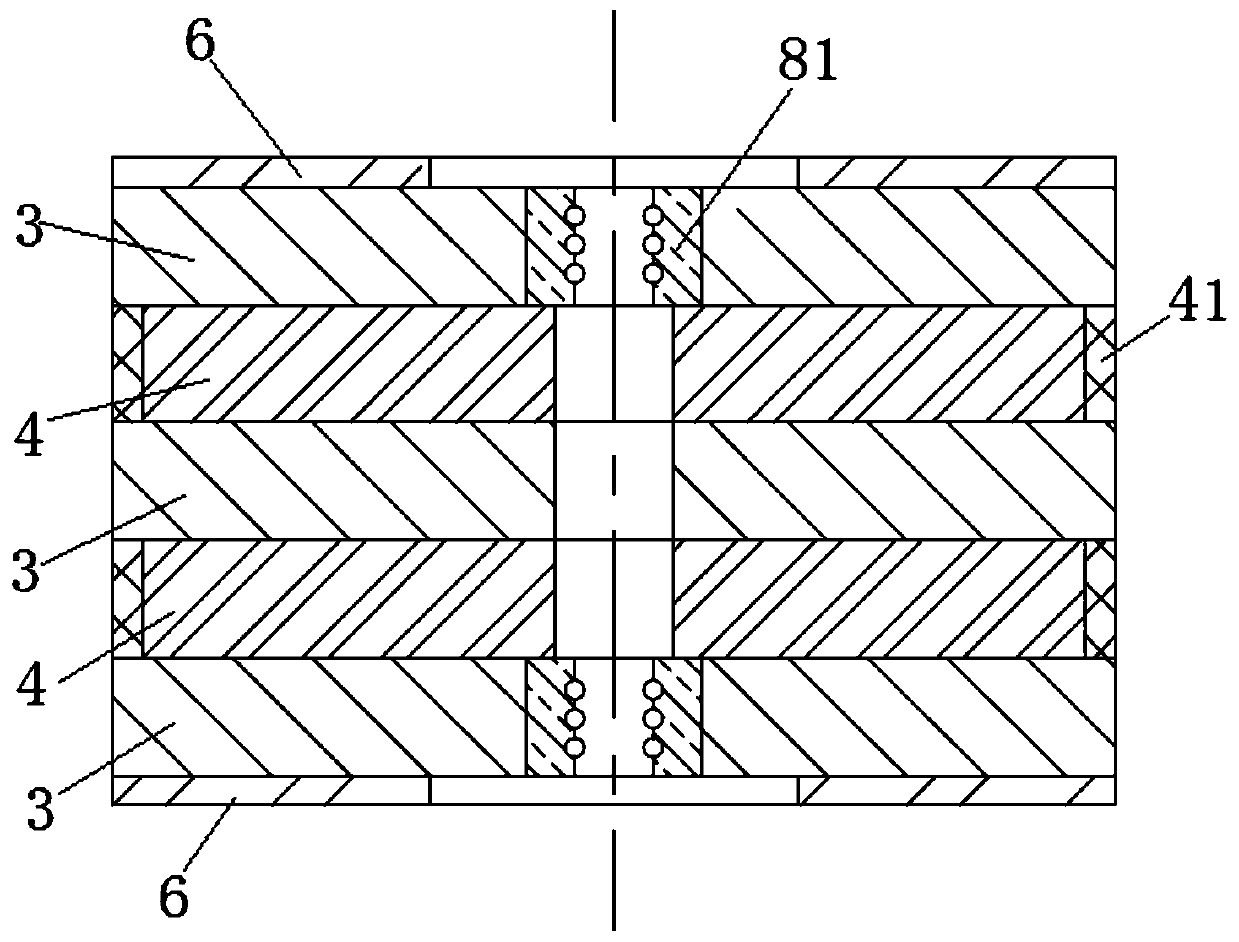

[0061] This embodiment provides a composite electromagnetic dynamic vibration absorber, which includes a housing 1 , two cover plates 2 , a mover, a vibration guide assembly, a coil 5 and a coil slot 11 . The two cover plates 2 are the upper cover plate and the lower cover plate respectively. The cover plate 2 is a flat plate structure, the outer shell 1 is closed in the circumferential direction, and has an open structure at both ends. The upper cover plate and the lower cover plate are respectively sealed in the shell 1 Both ends are open, forming a closed installation cavity with the shell 1, such as figure 1 As shown, stepped surfaces are provided at the openings at the upper and lower ends of the housing 1, and the corresponding two cover plates 2 are provided with matching stepped surfaces in the circumferential direction, and the two stepped surfaces are fitted together to form a seal. In this embodiment, the housing 1 Made of soft magnetic material. Mounting holes can...

Embodiment 2

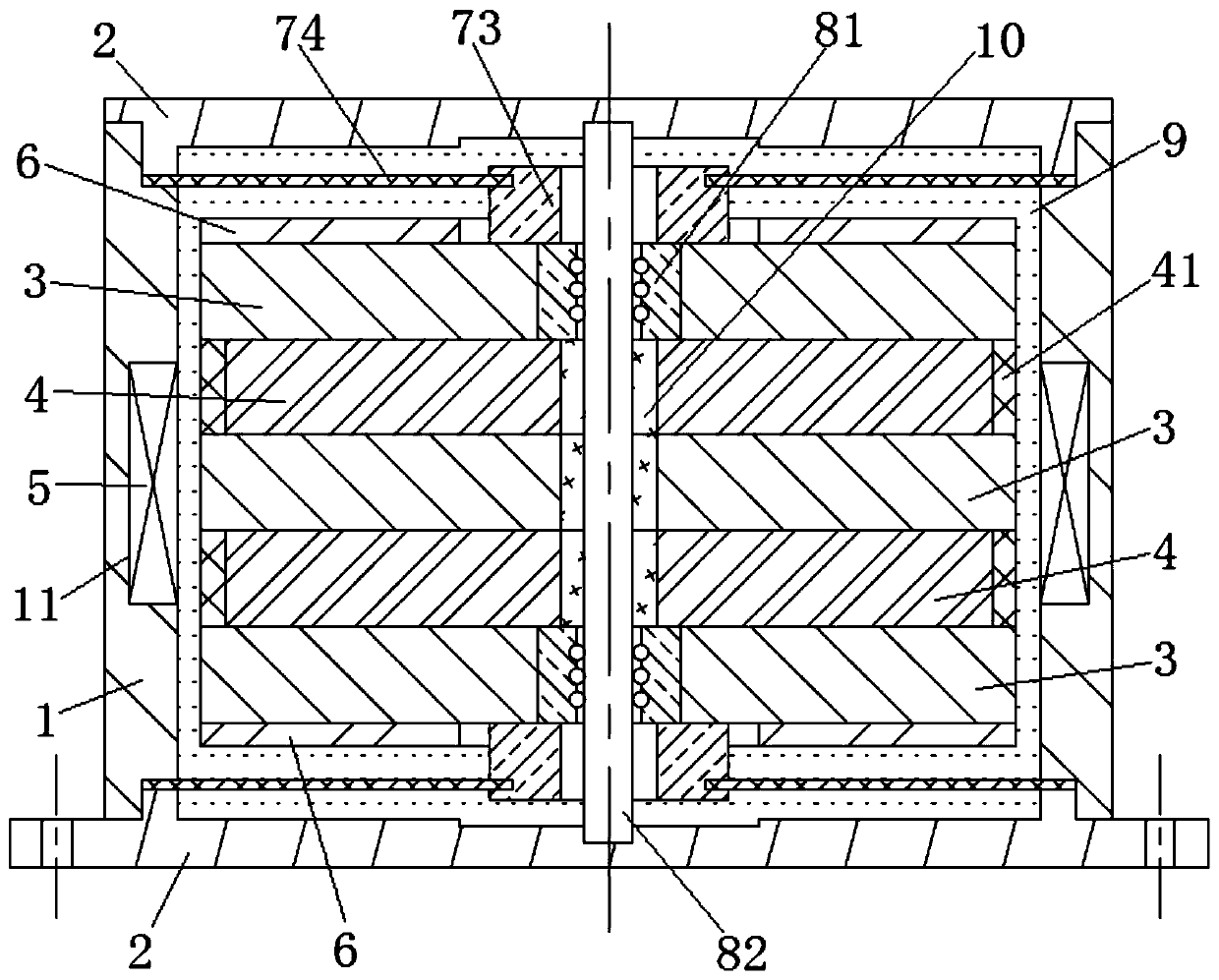

[0072] This embodiment provides a composite electromagnetic dynamic vibration absorber. Compared with the technical solution of Embodiment 1, the difference is that, as figure 2 As shown, the limit part in the vibration guide assembly adopts the flange 73, the flange 73 is coaxially threaded on the guide rod 82 and fixed on the mover core 3 at both ends of the mover, the flange 73 is located at the two ends of the auxiliary permanent In the inner ring of the magnet 6, the elastic member adopts a leaf spring 74, which is distributed symmetrically with respect to the flange 73. In this embodiment, the leaf spring 74 is circular, and the edge of the circular inner ring is fixed on the outer peripheral surface of the flange 73. , the edge of its outer ring is fixed on the inner step where the cover plate 2 and the casing 1 are sealed. When the mover is in a balanced state, the surface of the leaf spring 74 is arranged perpendicular to the axial direction of the mover.

[0073] As...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com