Reflecting film and preparation method thereof

A technology of reflective film and mixture, applied in the direction of reflective reflectors, etc., can solve the problems of small space, moisture absorption and dimensional stability of the light guide plate, etc., to avoid scratches and top whitening, excellent scratch resistance and top whitening resistance , Improve the effect of reflectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

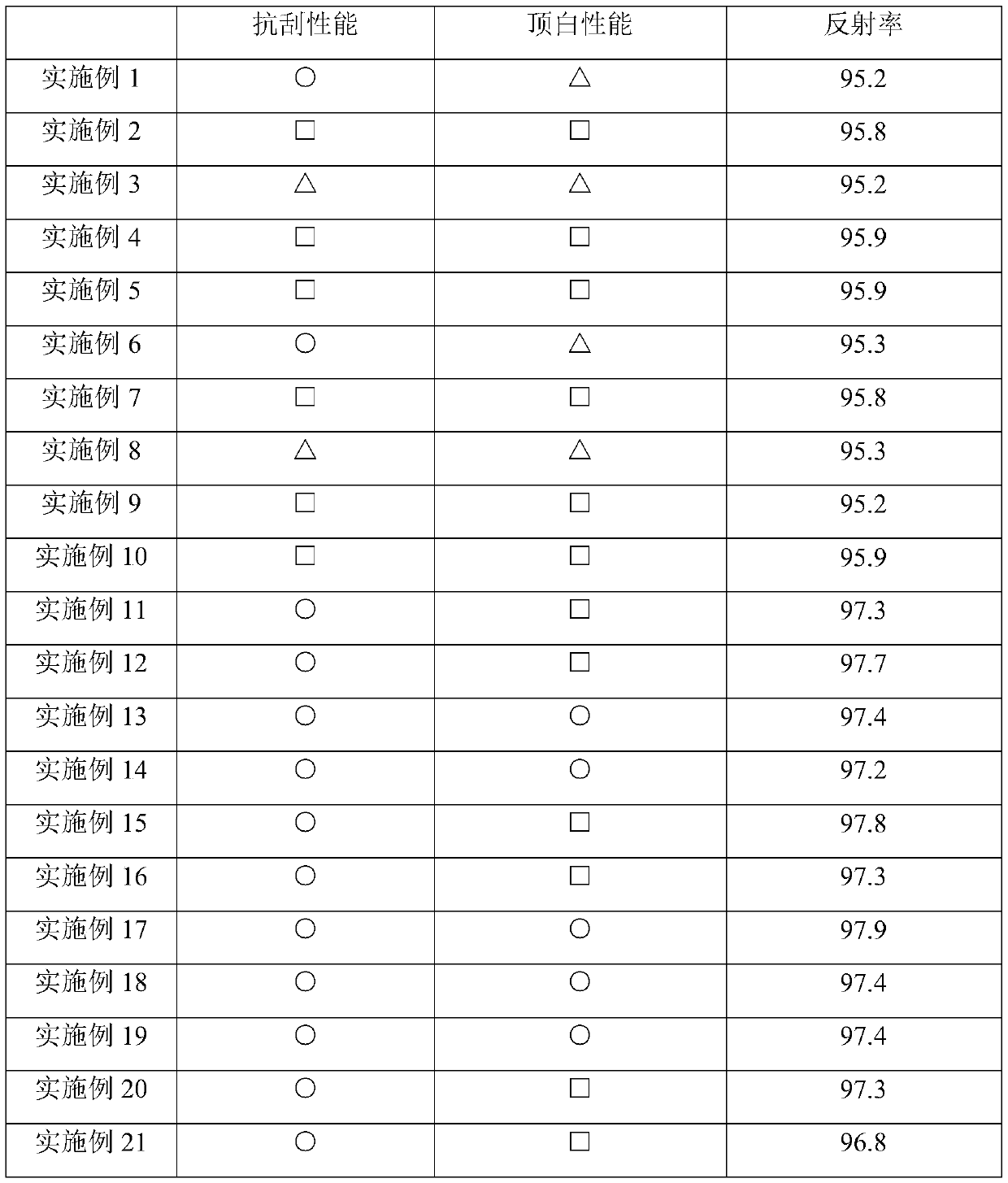

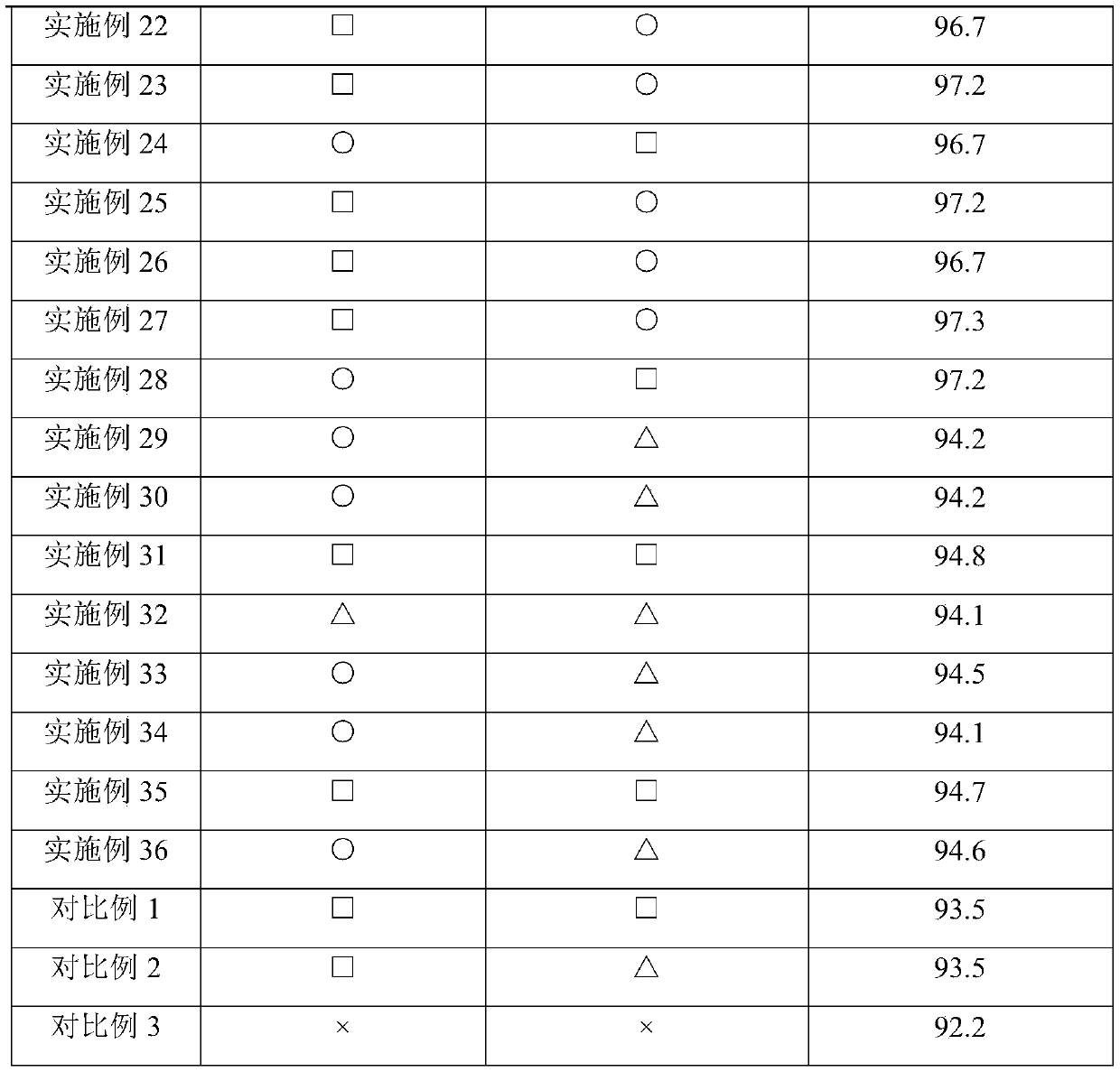

Examples

preparation example Construction

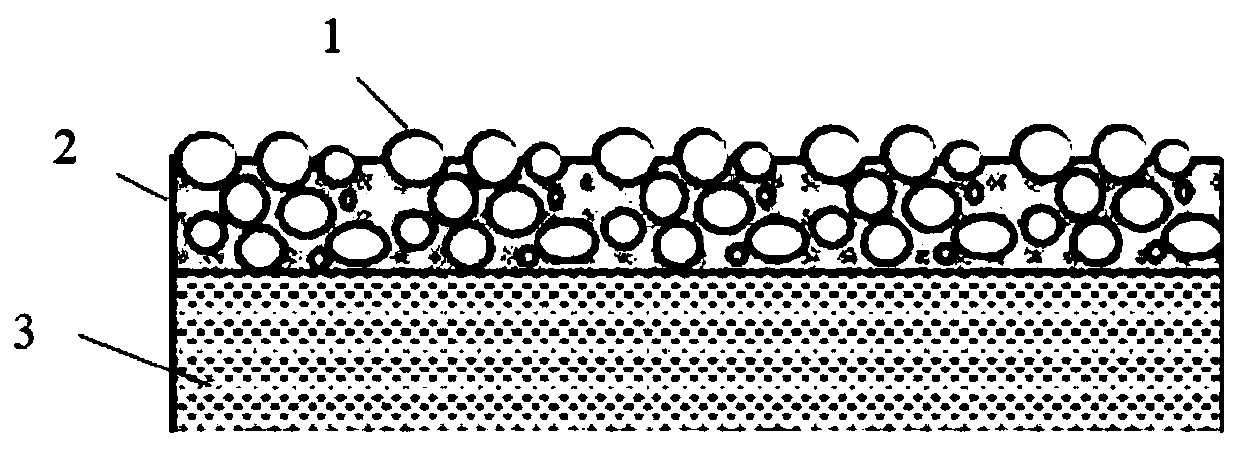

[0011] see figure 1 , the invention provides a kind of preparation method of reflective film, it comprises the following steps:

[0012] S1, providing a mixture, the mixture including porogen particles and matrix;

[0013] S2, coating the mixture on the surface of a substrate 3, and forming an isolation layer 2 on the surface of the substrate; and

[0014] S3, heat-treating the substrate 3 coated with the mixture to decompose the porogenic particles and release gas to form a plurality of pores, and at the same time, some of the pores protrude from the surface of the isolation layer 2 to form multiple pores. a convex structure to obtain the reflective film.

[0015] In step S1, the material of the matrix is at least one of polymethyl methacrylate, styrene-methyl methacrylate copolymer, thermoplastic polyurethane elastomer, polyethylene terephthalate . Considering the flexibility of the material, preferably, the material of the matrix is one of thermoplastic polyurethane...

Embodiment 1

[0028] Add ammonium bicarbonate to heat-cured polymethyl methacrylate glue, and the mass ratio of glue to sodium bicarbonate is 100:0.01. Stir at high speed with a high-speed mixer for 15 minutes, and then disperse the ammonium bicarbonate in the glue evenly. Then the uniformly stirred coating solution is evenly coated on the surface of the base film by a coating roller, and the isolation layer is dried and foamed in a 90°C oven for 1 minute, so that the total number of cells inside and on the surface of the isolation layer reaches: 10 2 piece / m 2 , the pore diameter of the internal cells is 0.1 μm-5 μm, the height of the convex structure on the surface is 5 μm-15 μm, and the reflective film is obtained.

Embodiment 2

[0030] Add ammonium bicarbonate to UV polymethyl methacrylate glue, and the mass ratio of glue to ammonium bicarbonate is 100:2. Stir at high speed with a high-speed mixer for 15 minutes, and then disperse the ammonium bicarbonate in the glue evenly. Then the evenly stirred coating solution is evenly coated on the surface of the base film by the coating roller, and the isolation layer is dried and foamed in a 120°C oven for 2 minutes, and then 450mJ / cm 2 The high-pressure mercury lamp with high energy irradiates to make it solidify and form, so that the total number of cells inside and on the surface of the isolation layer reaches: 10 3 piece / m 2 , the pore diameter of the internal cells is 0.1 μm-2 μm, the height of the surface convex structure is 5 μm-7 μm, and the reflective film is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com