Laser virtual interaction system and method based on liquid crystal photoelectric effect

A photoelectric effect and virtual interaction technology, applied in the fields of microelectronics and optics, can solve the problems of unsatisfactory scanning speed and durability, unfavorable integration, large product volume, etc., and achieve easy production process, short response time and sensitive system Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Example 1:

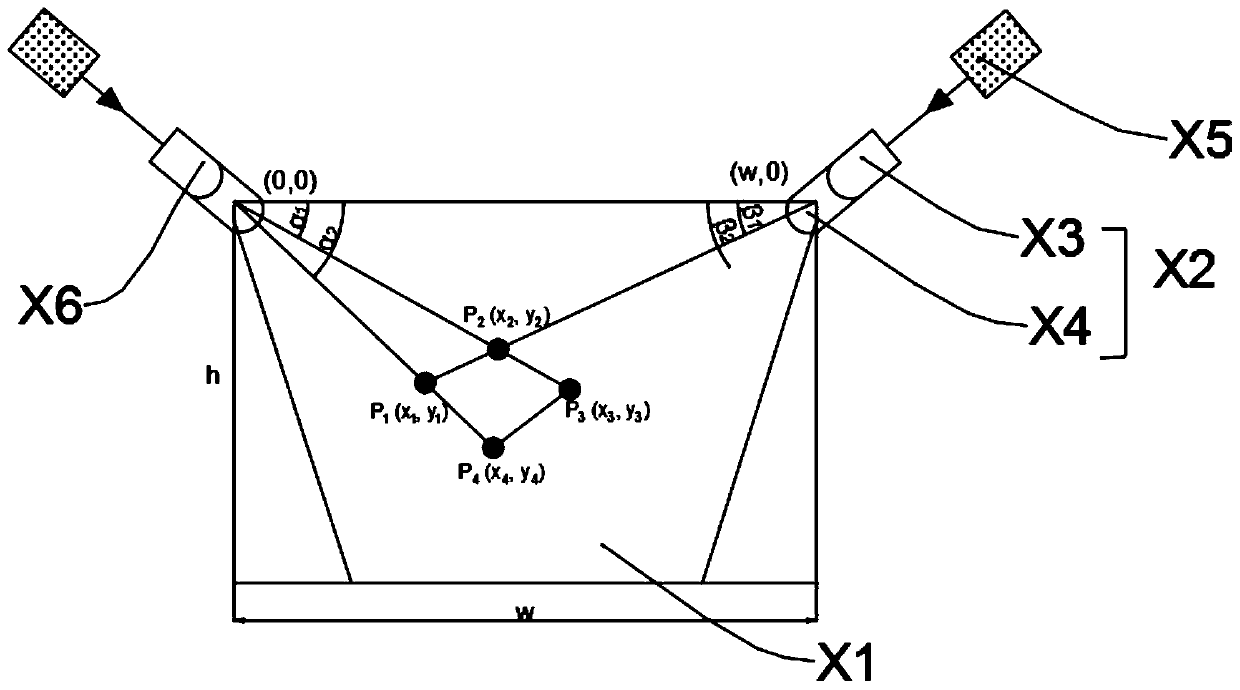

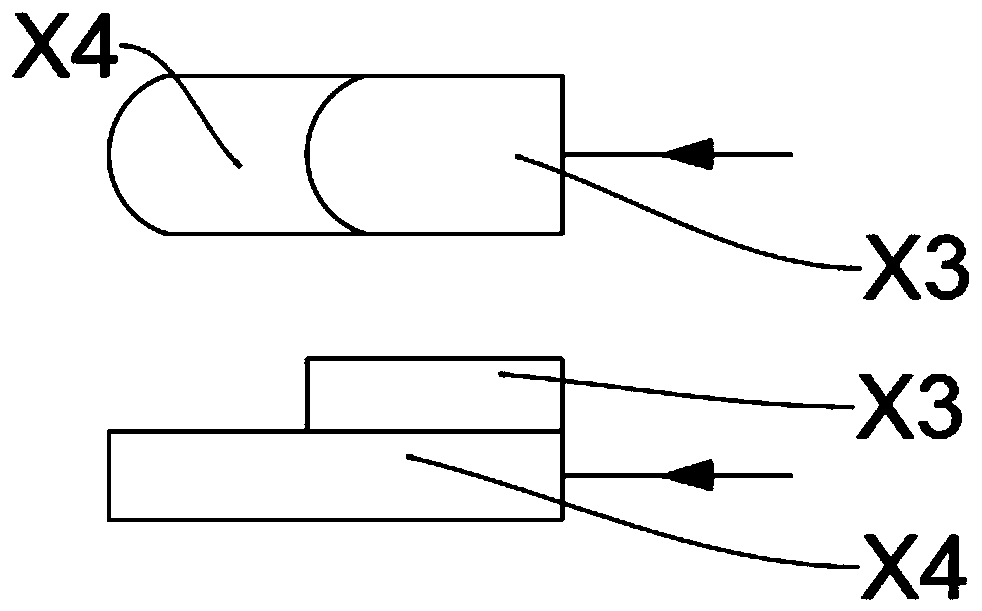

[0038] Such as figure 1 , figure 2 , a laser virtual interactive system based on liquid crystal photoelectric effect, including a working plane X1, a first laser scanning positioning system X2 and a second laser scanning positioning system X6 are set on the working plane, and the laser scanning positioning system includes a light emitter X5 and an infrared photoelectric probe X3 and the light transmitter X5 are connected with a laser scanning chip X4, and the laser scanning chip X4 regulates the laser to deflect and realize light scanning.

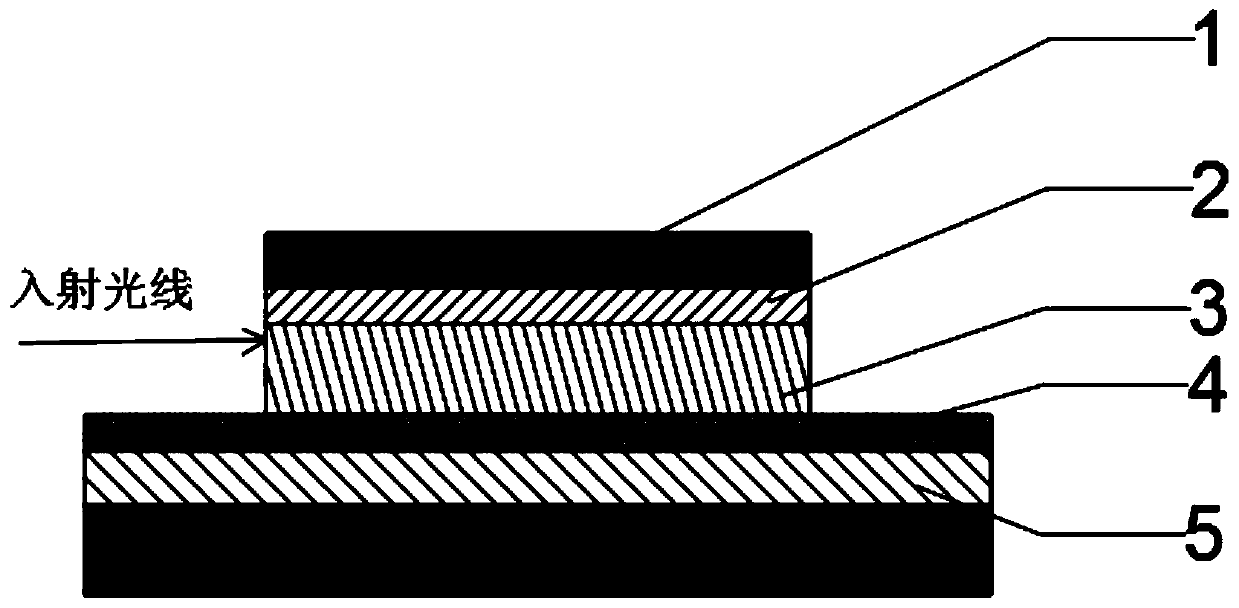

[0039] Such as image 3 , preferably, the laser scanning chip X4 includes a liquid crystal layer 3, an electrode driving layer 1 is arranged above the liquid crystal layer, an electrode driving device 2 is arranged above the electrode driving layer 1, and a photoconductive layer is provided below the liquid crystal layer 3, and the photoconductive layer includes a first The layer structure 4 and the second layer str...

Embodiment 2

[0052] In practical applications, the angle of the optical chip for liquid crystal scanning has certain limitations. In order to achieve a wider range of scanning angles, we can superimpose two or more chips with smaller scanning angles. Therefore, embodiment 2 is provided, as Figure 6 shown. Similarly, in this embodiment, the maximum scanning angle of a single optical chip used is about 50°, the width w of the working plane is 5m, and the height h is 3m. In other embodiments, other data can be used to realize the same technology Effect.

[0053] In Embodiment 2, the laser scanning system in Embodiment 1 is set to include a first light emitter and a second light emitter, the first light emitter is connected to the first laser scanning chip X41, and the second light emitter is connected to the second laser The scanning chip X42, the first laser scanning chip X41 and the second laser scanning chip X42 are arranged side by side so that the light deflection boundary of the first...

Embodiment 3

[0059] In this embodiment, a laser virtual interaction method based on liquid crystal photoelectric effect is also provided, including the following steps:

[0060] (1) Control the laser scanning chip in each group of laser scanning positioning system, adjust the light transmitter to deflect the light at a certain frequency, so as to realize scanning;

[0061] (2) Utilize the infrared photoelectric probes in each group of laser scanning positioning systems to determine the position of the scanning target in each group of laser scanning positioning systems through the time difference between the photoelectric probe receiving time and the light emitting time;

[0062] (3) Utilize the positions of different groups of laser scanning positioning systems and the positions in each group of laser scanning positioning systems to determine the final position of the scanning target;

[0063] (4) By adjusting the frequency of the laser scanning chip, real-time scanning of the motion track...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap