Prediction method for dendritic crystal growth in static molten steel based on parallel computing

A technology of parallel computing and prediction method, applied in the field of metallurgical continuous casting, can solve problems such as waste of computing resources, low efficiency, time-consuming efficiency, etc., and achieve the effects of improving computing efficiency, reducing computing time, and avoiding high costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

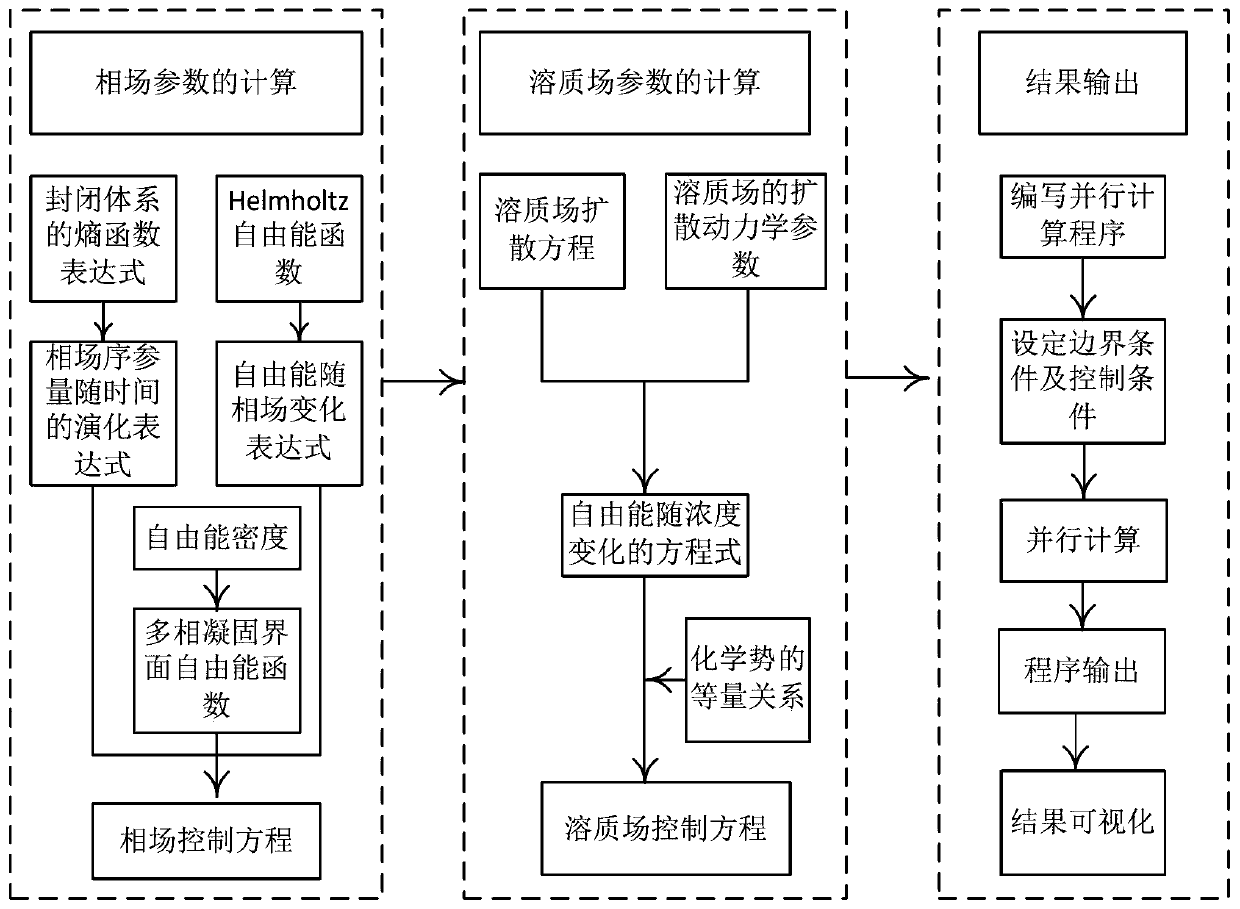

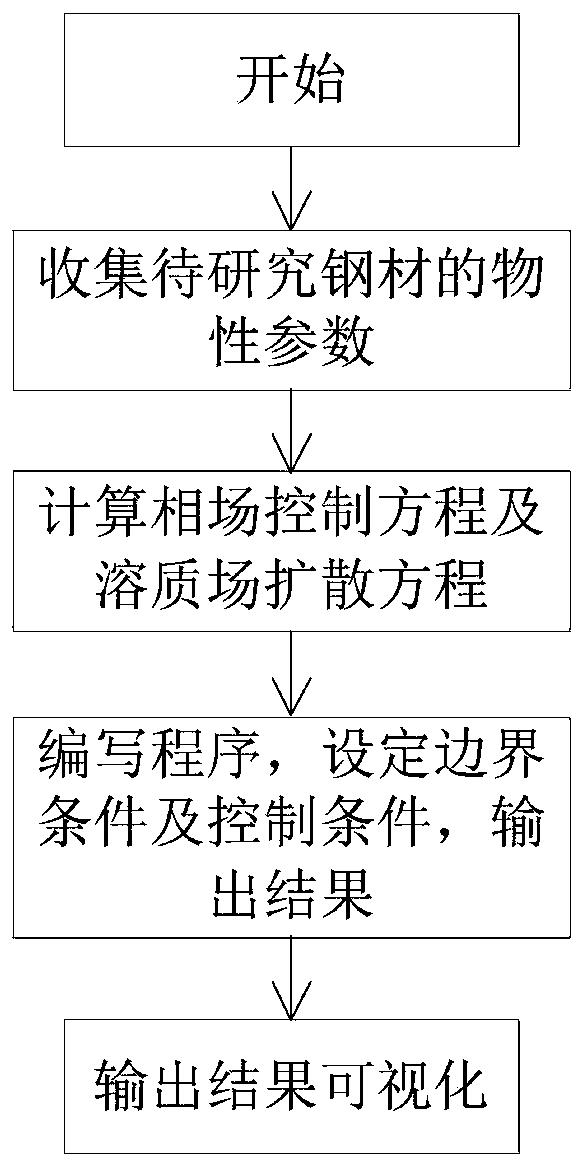

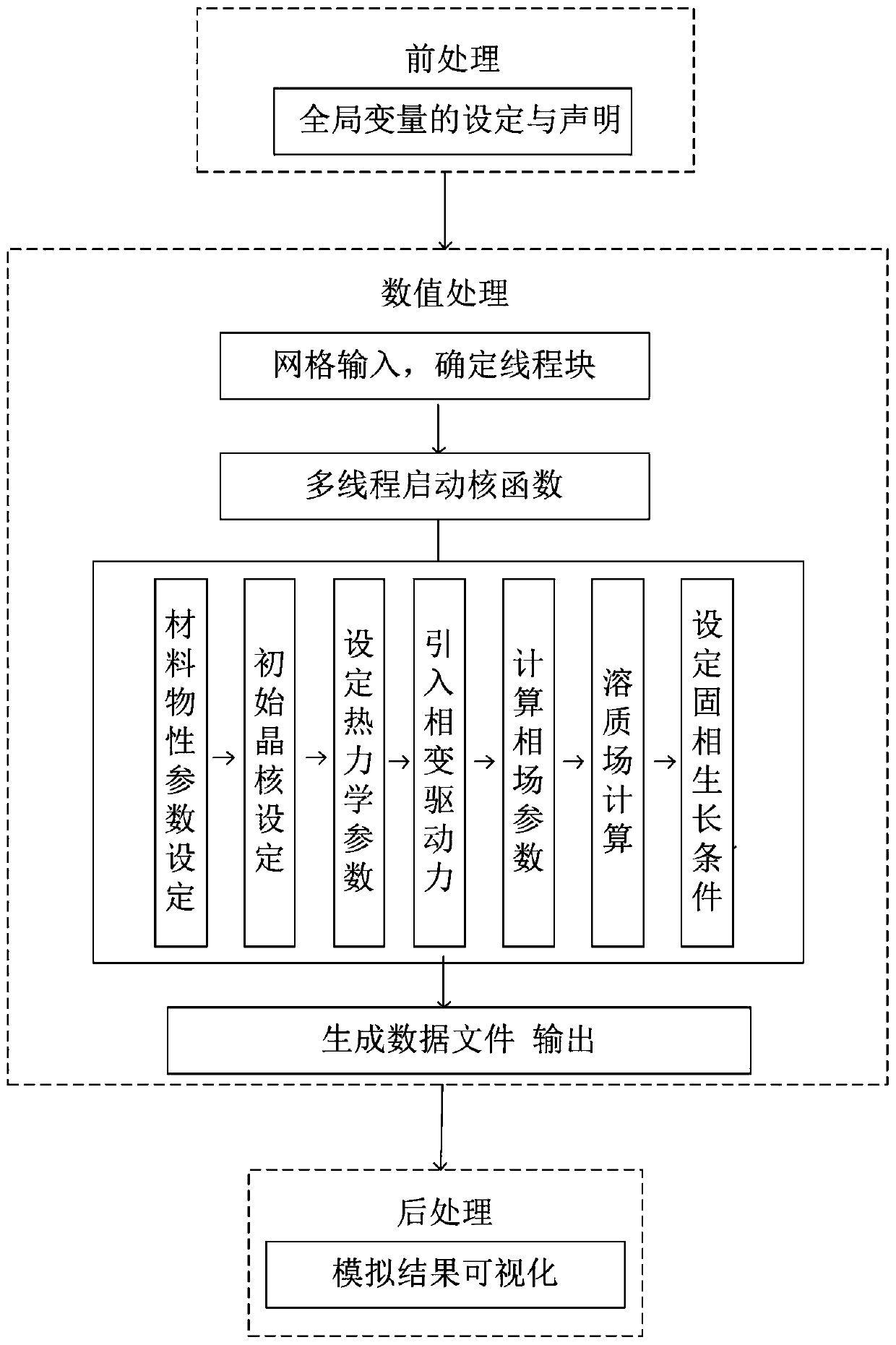

[0064] In this embodiment, the method for predicting dendrite growth in static molten steel based on parallel computing of the present invention is used to predict the dendrite growth of a low-carbon peritectic steel sample in a steel plant during the production process. like figure 1 Shown, the prediction method of dendrite growth in the standing molten steel based on parallel computing of the present invention, comprises the following steps:

[0065] Step 1: Collect physical property parameters and proportion data of each component of the steel to be studied; the physical property parameters include liquidus slope, melting point temperature, and molar volume.

[0066] In this embodiment, the carbon content of the low-carbon peritectic steel sample is 0.83 at.%, and the pseudo-binary phase diagram of the steel sample is as follows Figure 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com