Method for preparing semiconductor nanostructure through directional self-assembly and mask regulation and control

A directional self-assembly, nano-structure technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., to achieve the effect of reducing heavy dependence and multi-process tolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

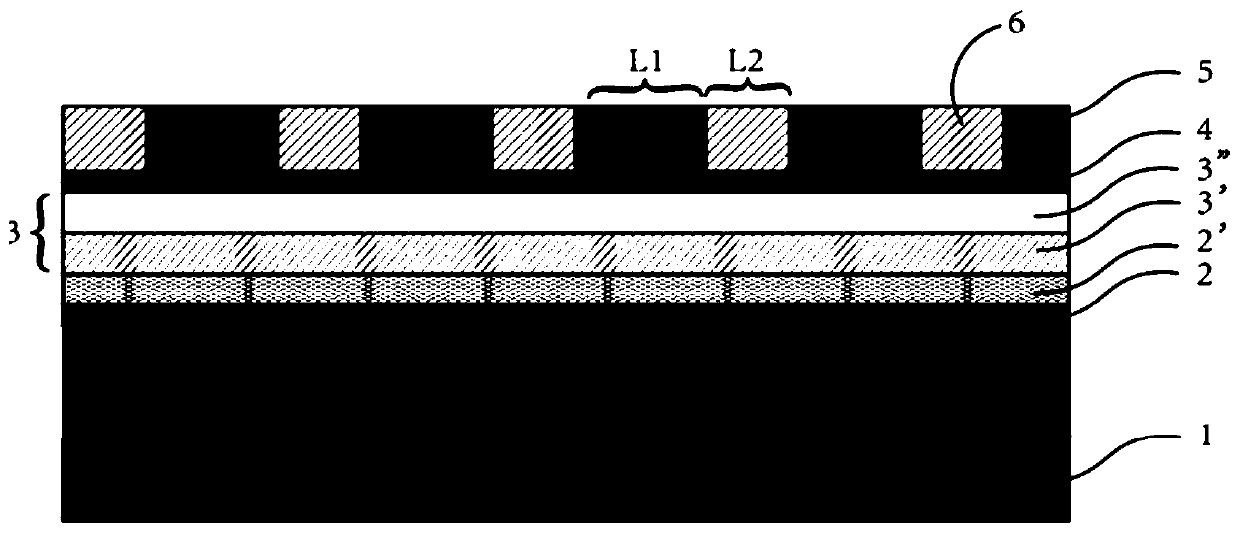

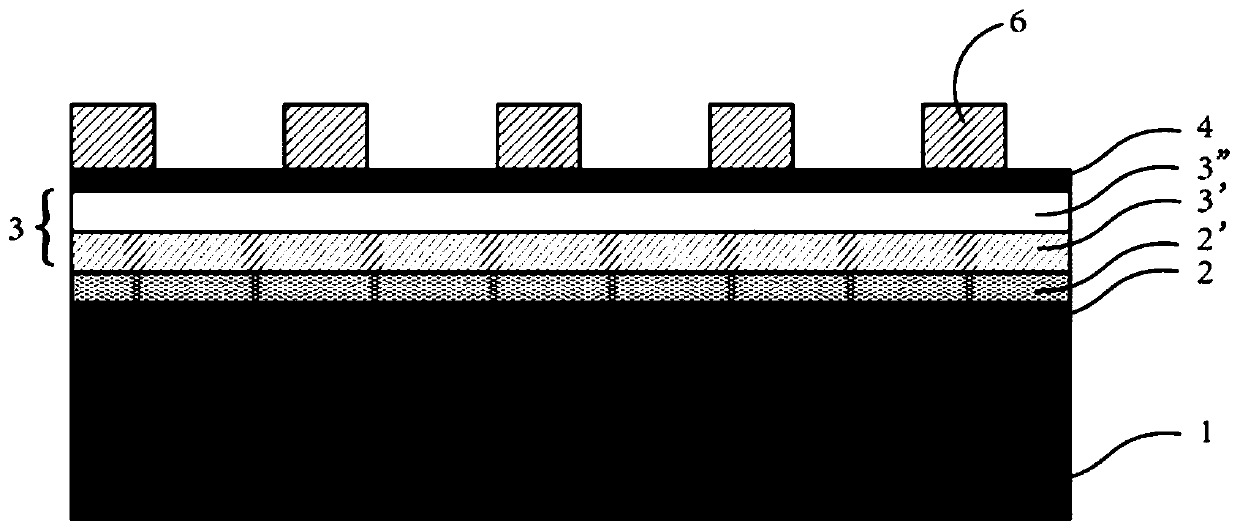

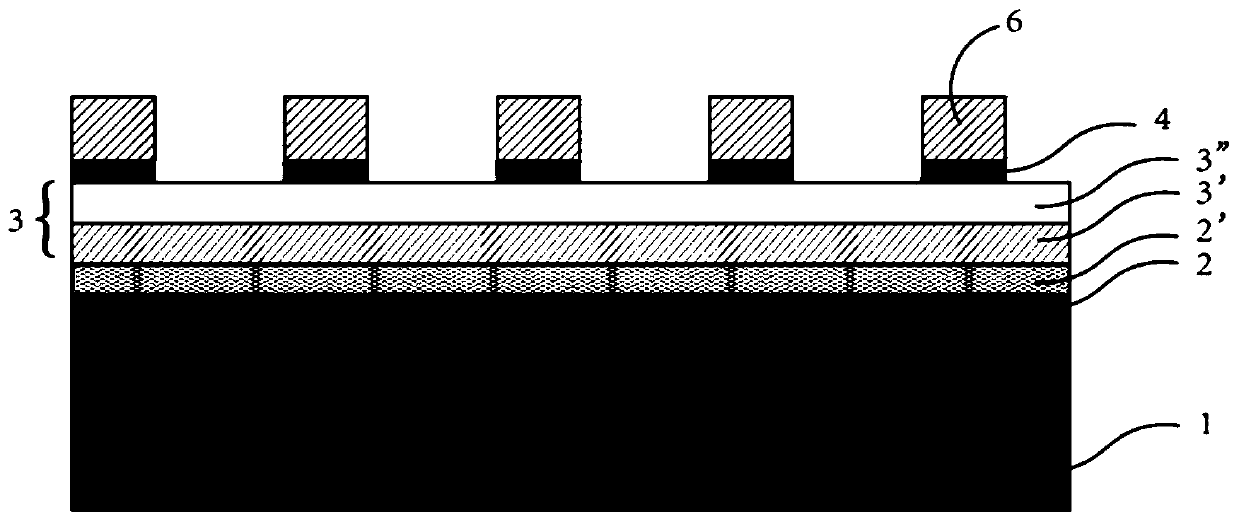

Method used

Image

Examples

Embodiment Construction

[0039] The following definitions and abbreviations are used for the interpretation of the claims and specification. As used herein, the terms "include", "include", "include", "include", "have", "have", "include" or any other variations thereof are intended to cover non-exclusive inclusion. For example, a composition, mixture, process, method, product or device that includes a series of elements is not necessarily limited to those elements, but may include other elements inherent in the composition, mixture, process, and method that are not explicitly listed or such , Items or equipment.

[0040] As used herein, the articles "a" and "an" before an element or component are intended to be non-limiting with respect to the number of instances (ie occurrences) of the element or component. Therefore, "a" or "an" should be understood to include one or at least one, and the singular form of an element or component also includes the plural, unless the number is obviously singular. The ap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com