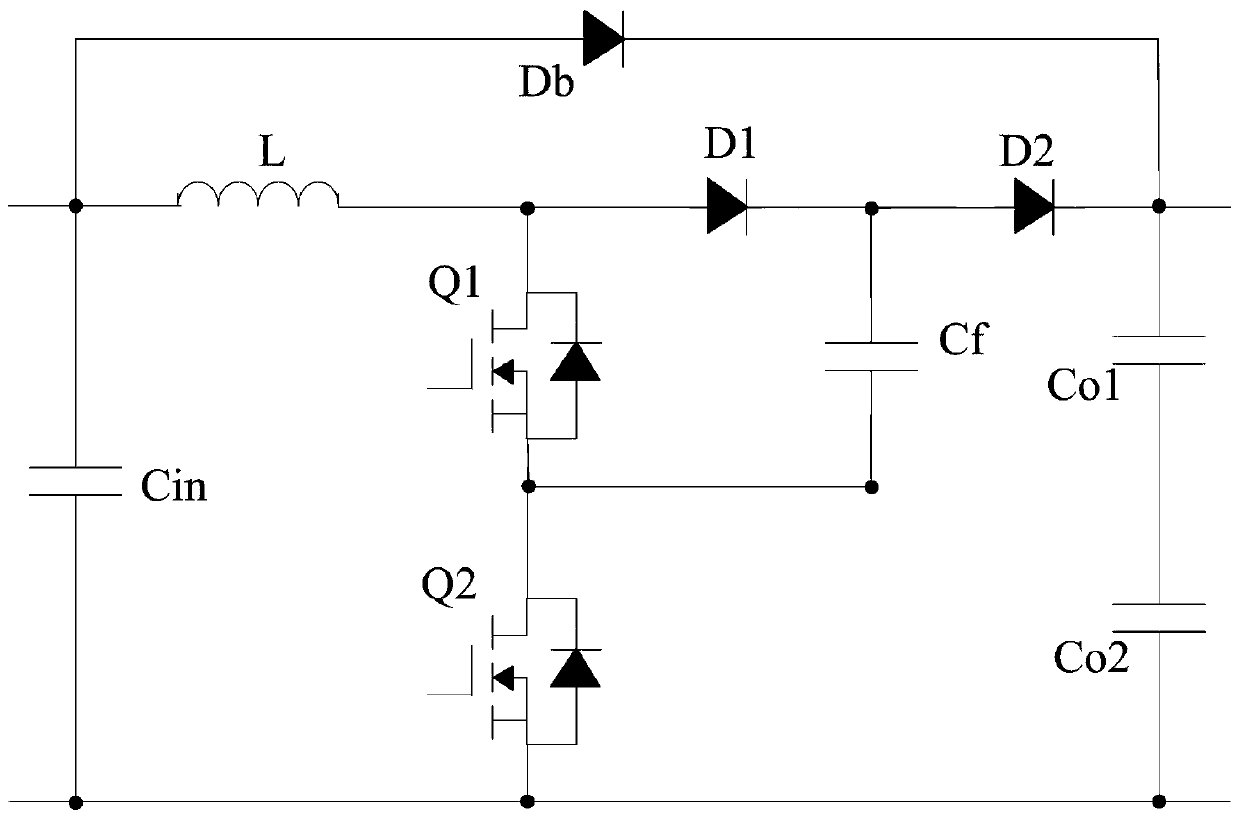

Capacitor clamping type direct-current conversion circuit

A DC conversion circuit and capacitor clamping technology, which is applied in the direction of converting DC power input to DC power output, adjusting electrical variables, and converting equipment without intermediate conversion to AC, can solve the problem of inability to ensure the reverse of the capacitor clamping DC conversion circuit. To achieve the effects of ensuring reliability, simplifying the circuit, and avoiding uneven voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

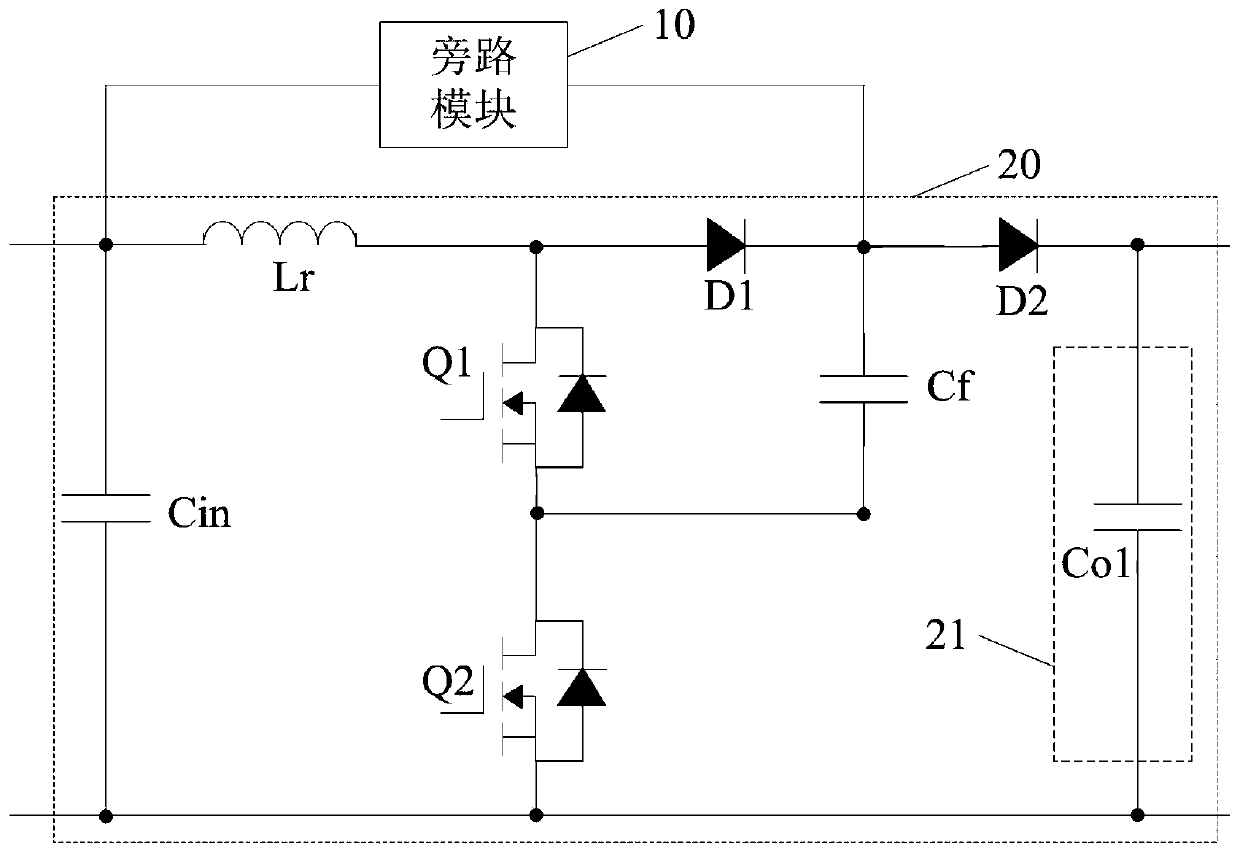

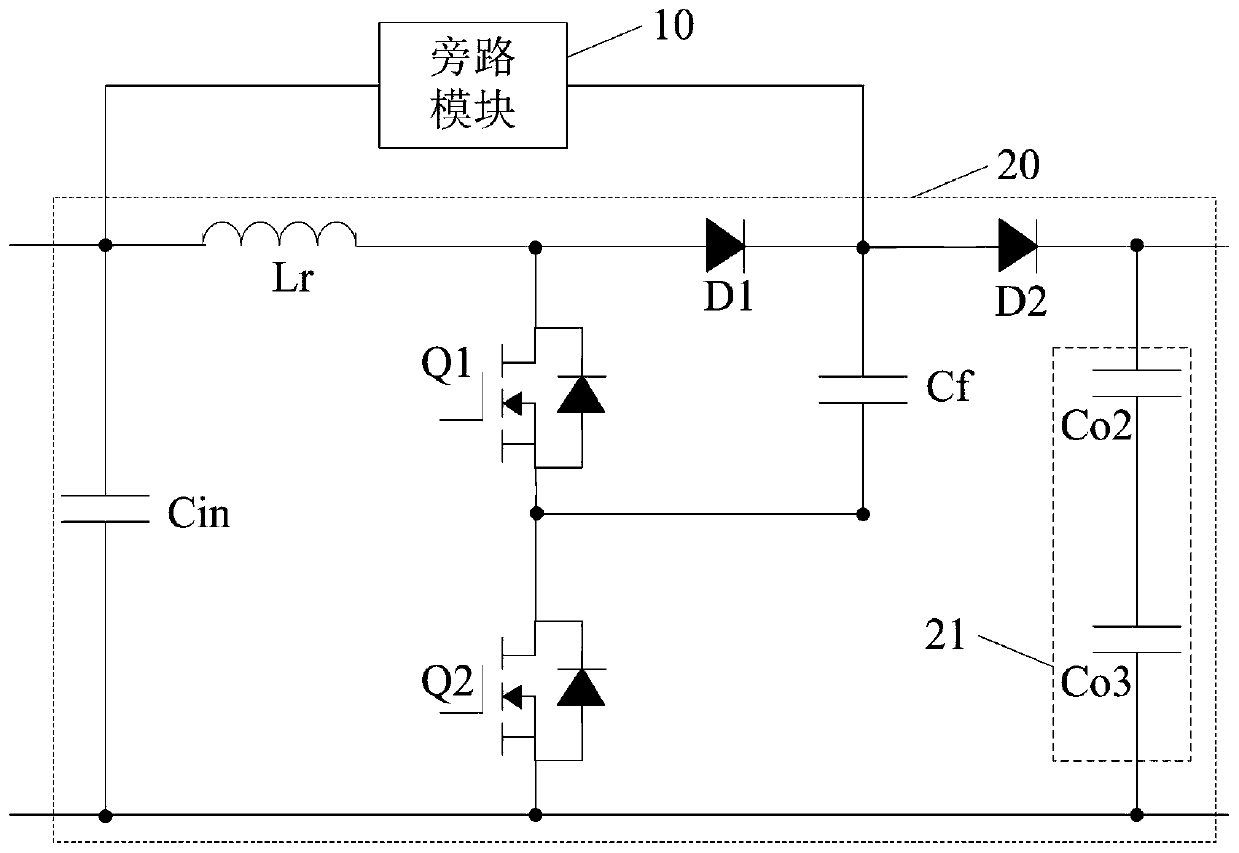

[0076] Another embodiment of the present application provides an implementation manner of a capacitor-clamped DC conversion circuit based on the above-mentioned embodiments, and further includes: a controller.

[0077] The first output terminal of the controller is connected to the control terminal of the first switching tube Q1 and the control terminal of the second switching tube Q2, and the controller is used to control the chopping operation of the first switching tube Q1 and the second switching tube Q2, so that the capacitance The clamping DC conversion circuit is in normal working condition.

[0078] If the bypass module 10 includes a bypass relay 30, the second output terminal of the controller is connected to the control terminal of the relay; road status.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com