Fuel cell separator conductive sheet and fuel cell separator

A technology for fuel cells and separators, which is applied to fuel cell parts, fuel cells, circuits, etc., can solve the problems of poor fiber entanglement, low strength of separators, and poor formability, etc. Uniform distribution or aggregation, excellent strength, and the effect of improving bending elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

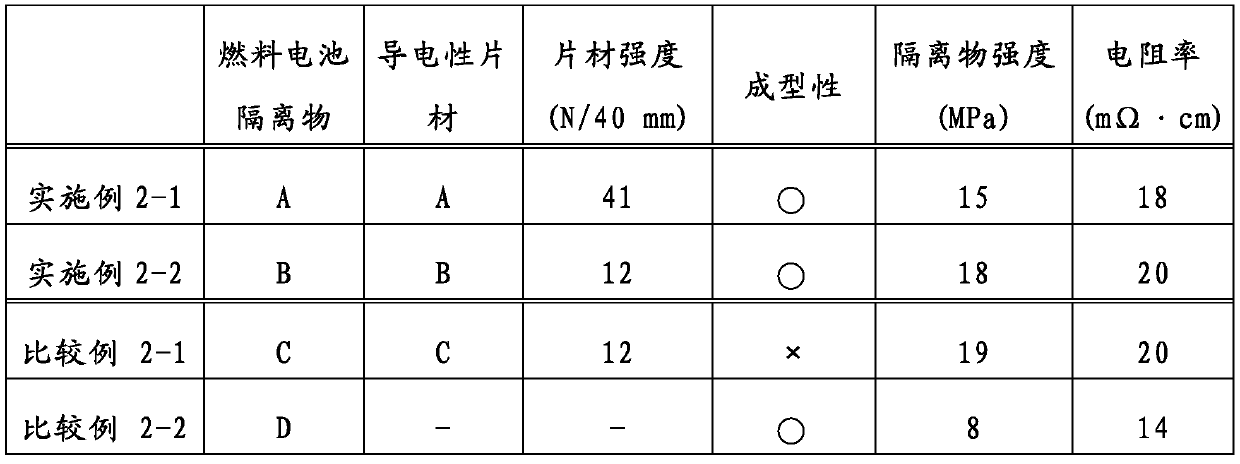

Examples

Embodiment 1-1

[0073] 73 parts by mass of artificial graphite, 6 parts by mass of PAN-based carbon fiber, 4 parts by mass of cellulose fiber and 17 parts by mass of PP fiber were put into water and stirred to obtain a fiber material slurry. This slurry was sheeted to prepare a conductive sheet A. The basis weight of conductive sheet A is 264g / m 2 .

Embodiment 1-2

[0075] 84 parts by mass of artificial graphite, 6 parts by mass of PAN-based carbon fiber, 5 parts by mass of cellulose fiber and 5 parts by mass of PP fiber were put into water and stirred to obtain a fiber material slurry. This slurry was sheeted to prepare a conductive sheet B. The basis weight of conductive sheet B is 229g / m 2 .

Embodiment 2-1

[0080] The conductive sheet A was placed at 185° C. for 5 minutes to obtain a resin-impregnated precursor. A fuel cell separator A (thickness 0.15 mm) was obtained by naturally cooling and compression-molding the precursor from a mold temperature of 185° C. to 100° C. while maintaining a molding pressure of 47 MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com