A kind of preparation method of three molybdenum phosphide coating

A technology of tri-molybdenum phosphide and coating, applied in the direction of coating, metal material coating process, etc., can solve the problems of strong use limitation of coating, only application of aluminide coating, loss of protective performance, etc., to achieve the protective effect Significant, controllable coating thickness, significant effect of anti-oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] A preparation method for a molybdenum phosphide coating, comprising the following steps:

[0039] Step 1: Prepare materials

[0040] Weigh raw molybdenum products and phosphides, and control the weight ratio of molybdenum products and phosphides to (50-100): (1-20);

[0041] The phosphide is a powder or a massive object, which can be selected from aluminum phosphate, phosphorus pentoxide, aluminum hypophosphite and other substances that generate phosphorus pentoxide, phosphine or elemental phosphorus at high temperatures;

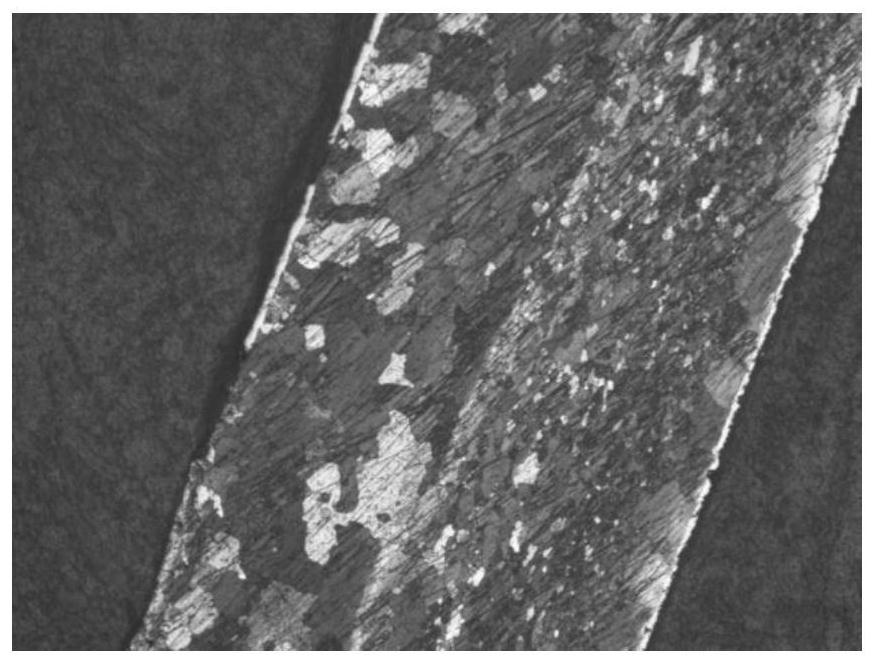

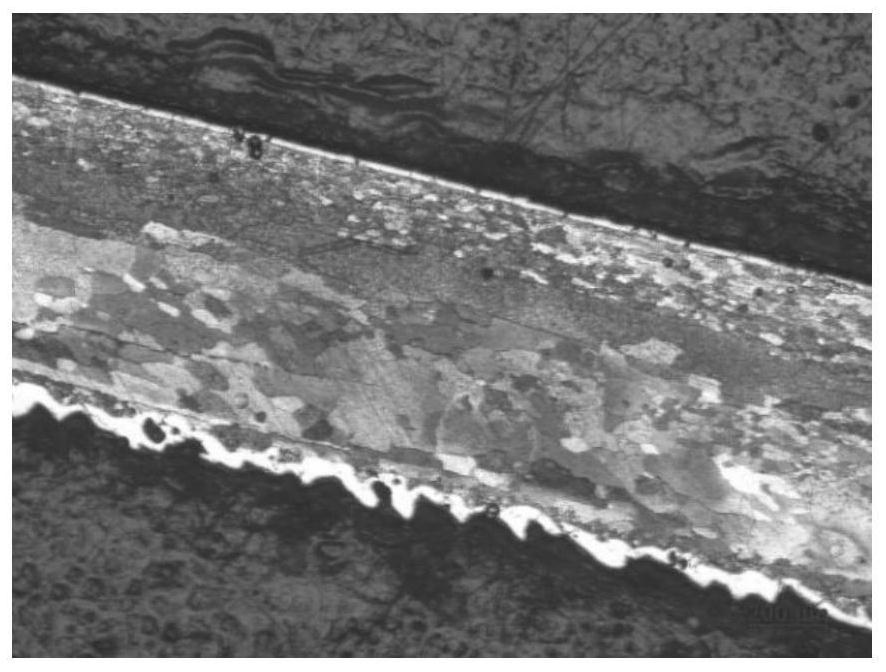

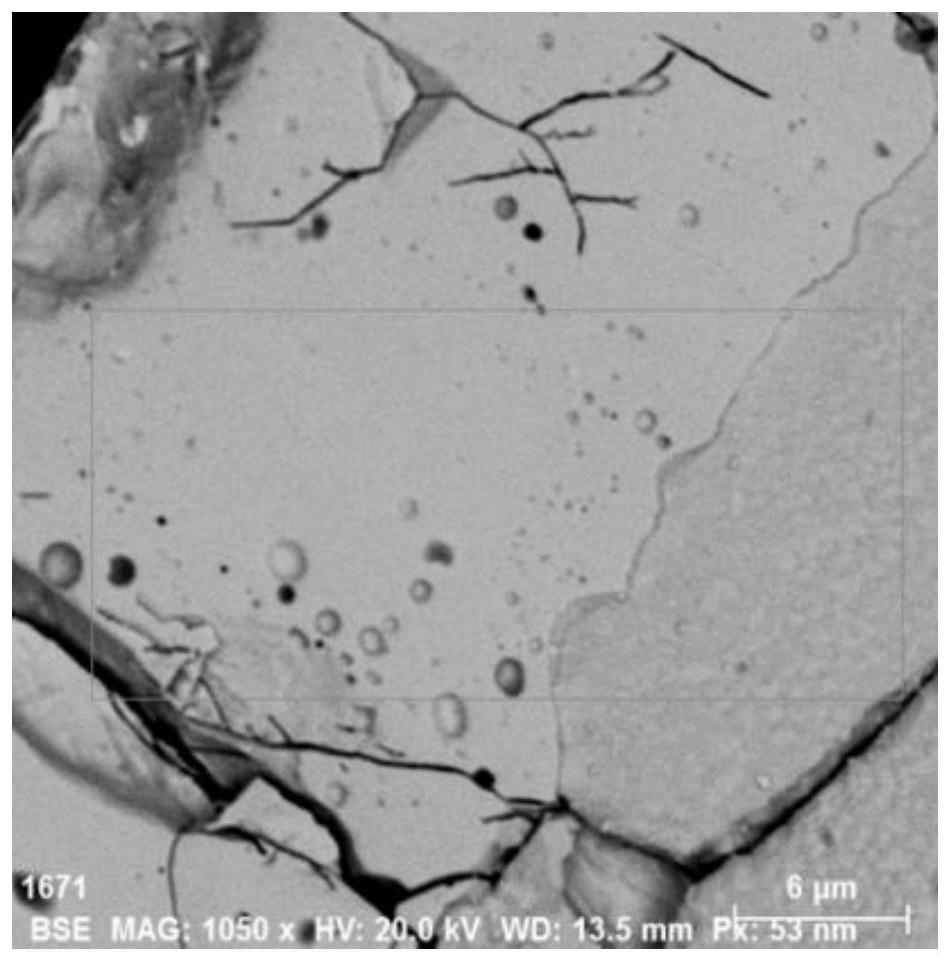

[0042] The molybdenum products are plates, rods, blocks or powders, and the internal grain size is less than 70 μm; the material of the molybdenum products can be pure molybdenum, molybdenum-lanthanum alloy or molybdenum-titanium-zirconium alloy, etc. In order to ensure rapid chemical reaction, the internal grain size The particle size should be as small as possible.

[0043] Step 2: Sintering in a hydrogen atmosphere

[0044] Put the weighed phos...

Embodiment 1

[0052] Prepare a piece of molybdenum corrugated plate with a weight of about 100g and a grain size of about 50μm; weigh 10g of aluminum phosphate, and then place the aluminum phosphate in an alumina crucible, and the height of the crucible should not exceed 5cm. The crucible is placed in the center of the loading table of the sintering furnace, the molybdenum corrugated plate is placed on one side and the aluminum oxide block is placed below to support it, so that the bottom side of the molybdenum corrugated plate can also contact the phosphide. Combine the furnace, vacuumize the sintering furnace until the vacuum degree is better than 10kPa, then turn off the vacuum pump and feed nitrogen, the nitrogen flow rate is 400ml / min, when the pressure in the furnace reaches 200kPa, vacuumize again, and the furnace cleaning operation can be completed once. After washing the furnace twice, feed hydrogen and control the flow of hydrogen to 400ml / min. Then, power is supplied to the sinte...

Embodiment 2

[0054]Prepare a piece of molybdenum corrugated plate with a weight of about 100g and a grain size of about 50μm; weigh 20g of phosphorus pentoxide, and then place aluminum phosphate in an alumina crucible, and the height of the crucible should not exceed 5cm. The crucible is placed in the center of the loading table of the sintering furnace, the molybdenum corrugated plate is placed on one side and the aluminum oxide block is placed below to support it, so that the bottom side of the molybdenum corrugated plate can also contact the phosphide. Put the furnace together, vacuumize the sintering furnace until the vacuum degree is better than 10kPa, then turn off the vacuum pump and feed nitrogen, the nitrogen flow rate is 400ml / min, when the pressure in the furnace reaches 200kPa, vacuumize again, and the furnace cleaning operation can be completed once. After washing the furnace twice, feed hydrogen and control the flow of hydrogen to 400ml / min. Then, power is supplied to the sin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com