Control method, device and equipment of dopant for mono-crystalline silicon growth and storage medium

A control method and dopant technology, which is applied in the field of crystal manufacturing and can solve problems such as resistivity that does not meet the requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

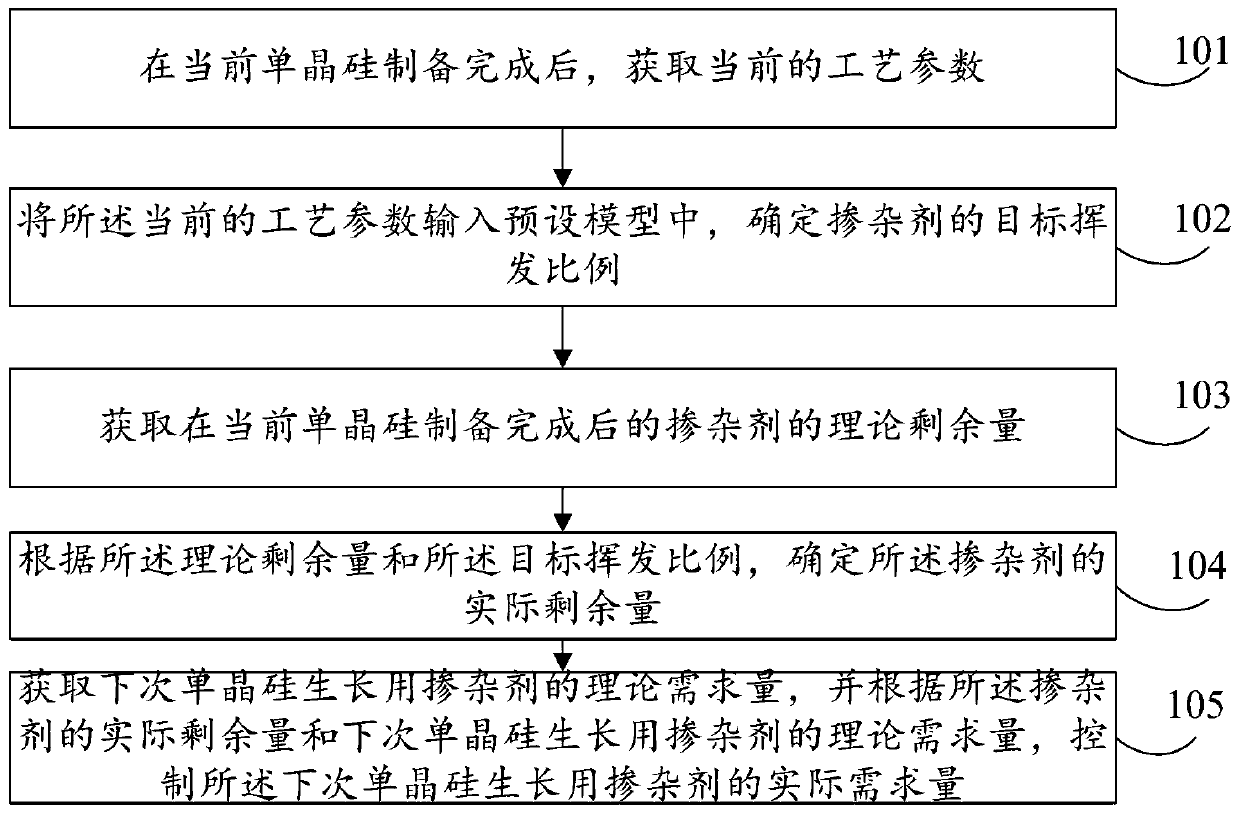

[0052]An embodiment of the present invention provides a method for controlling dopants for growing single crystal silicon, such as figure 1 As shown, the method for controlling the level growth of single crystal silicon comprises the following steps:

[0053] Step 101, after the preparation of the current single crystal silicon is completed, the current process parameters are acquired.

[0054] In an embodiment of the present invention, the process parameters include: working power of the single crystal furnace, working pressure and time interval of the single crystal furnace between two adjacent single crystal silicon preparation operations. The current process parameters include: the working power of the single crystal furnace between the completion of the current monocrystalline silicon growth and the next filling, the working pressure of the single crystal furnace between the completion of the current monocrystalline silicon growth and the next filling, and the current sin...

Embodiment 2

[0134] Based on the above figure 1 For the single crystal silicon growth control method described in the corresponding embodiment, the following is an embodiment of the device of the present invention, refer to Figure 4 , which can be used to execute the method embodiment of the present invention.

[0135] An embodiment of the present invention provides a dopant control device for growing single crystal silicon, such as figure 2 As shown, the control unit includes:

[0136]The first acquisition module 201 is used to acquire the current process parameters after the current single crystal silicon preparation is completed;

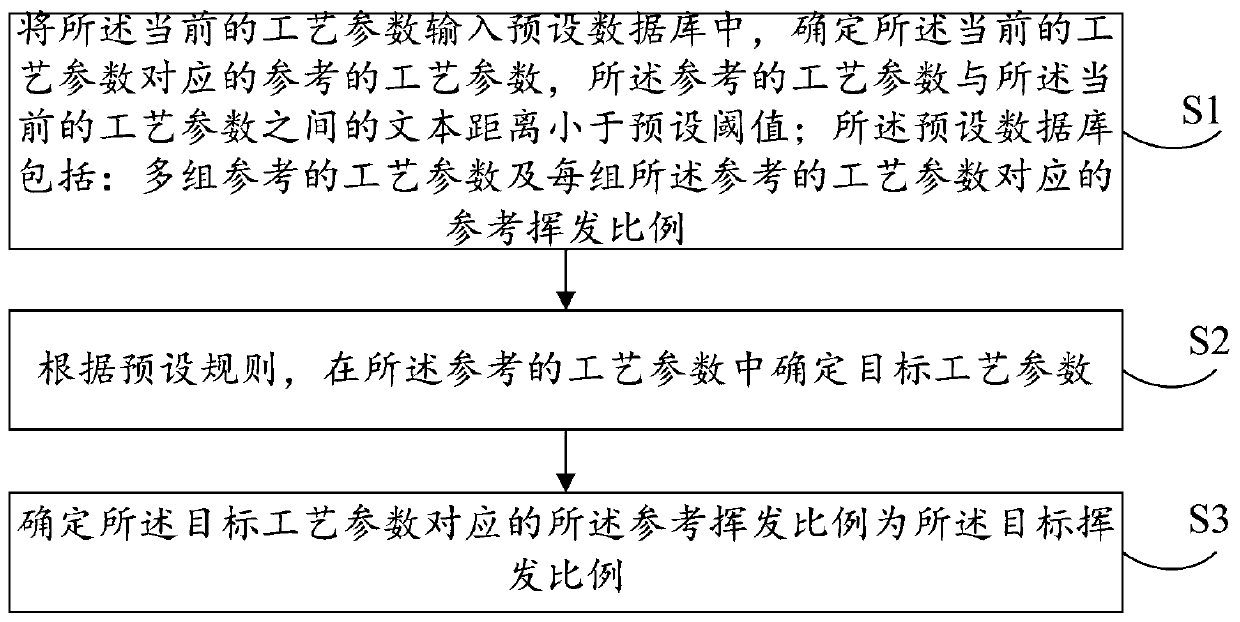

[0137] The first determination module 202 is configured to input the current process parameters into the preset model to determine the target volatilization ratio of the dopant;

[0138] The second obtaining module 203 is used to obtain the theoretical remaining amount of dopant after the preparation of the current single crystal silicon is completed;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com