Three-dimensional embossed cotton-layer-containing non-woven fabric and preparation method thereof

A non-woven, three-dimensional technology, applied in non-woven fabrics, textiles and papermaking, liquid repellent fibers, etc., can solve the problem of reverse osmosis of cotton-containing non-woven fabrics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

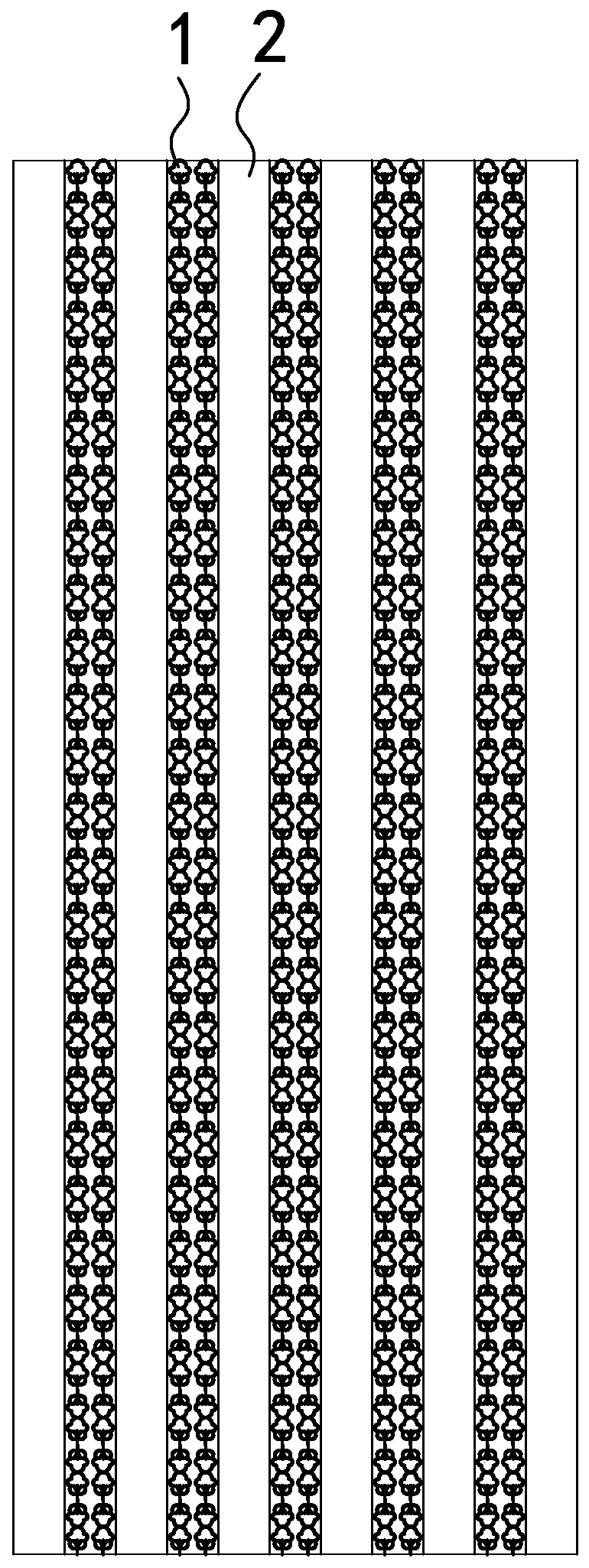

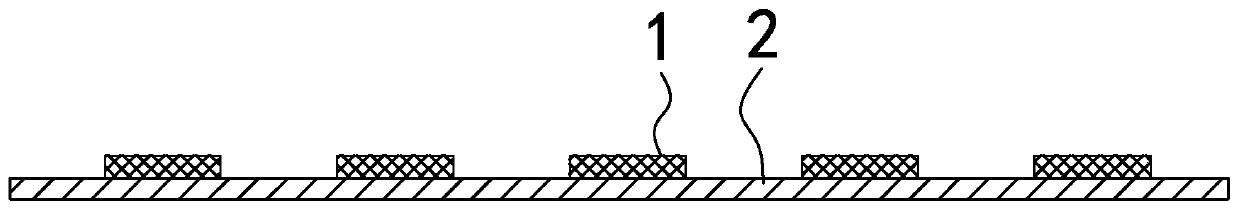

[0036] refer to Figure 1a , figure 2 , a method for preparing a three-dimensional embossed cotton layer non-woven fabric, comprising the steps of:

[0037]a. Prepare ES fiber and comb it into a web. This step is realized through two production links:

[0038] As a well-known ES fiber production process, it includes: polyethylene / polypropylene melt spinning - oiling - winding - bundling - drafting - oiling - crimping - drying - shearing - -Package.

[0039] The preparation link of the ES fiber of the present embodiment comprises the following steps:

[0040] a1, according to the known ES fiber preparation steps, polyethylene and polypropylene are melt-spun to obtain ES fiber filaments;

[0041] a2, carry out oiling treatment to the fiber filament tow of step 1 by oiling roller, oiling agent is the mixture of polyether silicone oil and isomeric alcohol ether, the weight ratio of polyether silicone oil and isomeric alcohol ether is 5: 1. The oiling rate is controlled at 0.2...

Embodiment 2

[0055] Embodiment 2: In view of the fact that the three-dimensional embossed cotton-containing layer non-woven fabric is applied on the surface material of diapers or sanitary napkins, Embodiment 2 provides a more friendly skin-friendly three-dimensional embossed cotton-containing layer non-woven fabric. The preparation method differs from Example 1 in that:

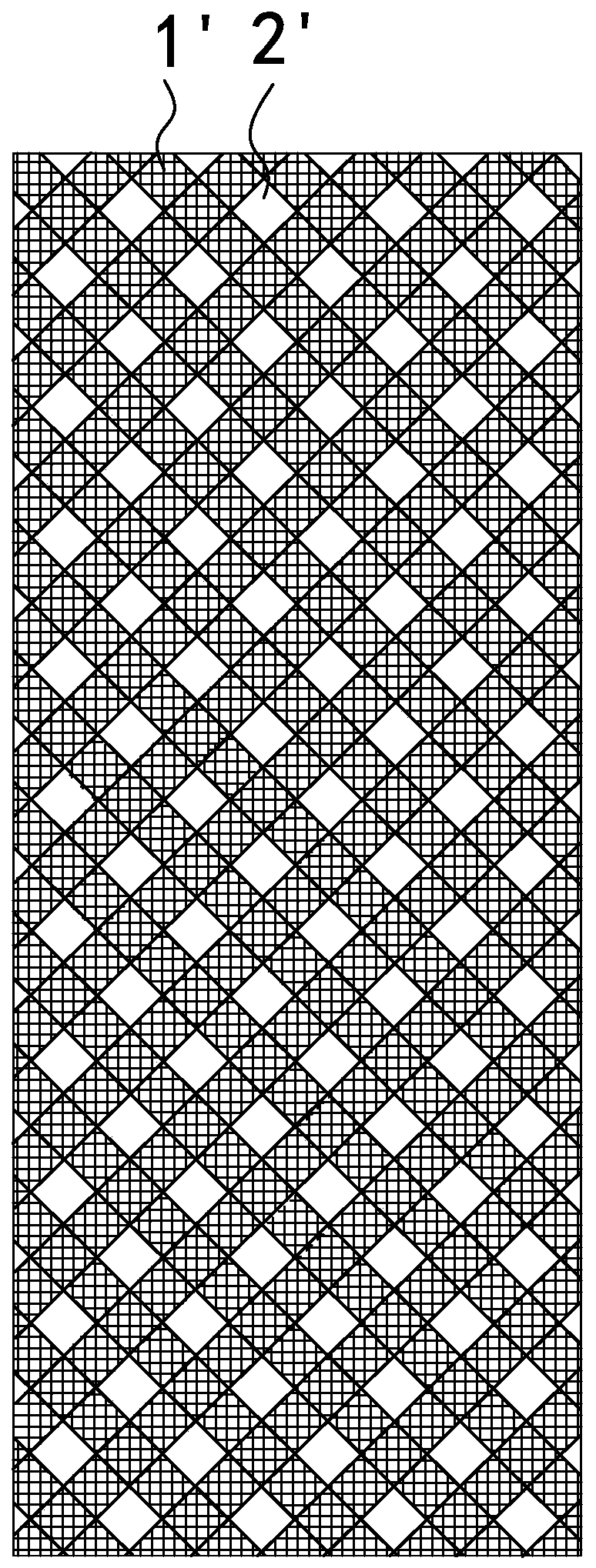

[0056] refer to Figure 1b , in the step b, the cotton fiber layer 1' is composed of a plurality of cotton fiber units tiled on the upper surface of the ES fiber layer 2' in a grid arrangement, and the laying area of the cotton fiber layer 1' occupies an area of ES 65% of the area of the fiber layer 2 ', this web forming process will greatly sacrifice the speed of the non-woven fabric production line, under the same process conditions, its power consumption will increase more than 20% relative to Example 1, but the obtained The skin-friendly touch of the three-dimensional embossed non-woven fabric is significantly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Square gram weight | aaaaa | aaaaa |

| Linear density | aaaaa | aaaaa |

| Square gram weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com