Biomass boiler furnace temperature and load forecasting method

A biomass boiler and furnace temperature technology, applied in combustion methods, lighting and heating equipment, combustion chambers, etc., can solve the problems of inaccurate prediction of biomass boiler furnace temperature and load, insufficient data utilization, and huge data volume. To achieve the effect of ensuring real-time and originality, ensuring real-time and rapidity, and eliminating the influence of correlation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

[0020] Aiming at the existing problems, the present invention provides a method for predicting the furnace temperature and load of a biomass boiler. Based on the principal component analysis method and bipolar neural network, the temperature and load prediction of the boiler furnace can be predicted more quickly and accurately, and at the same time, the amount of input data and the load can be reduced. Calculations.

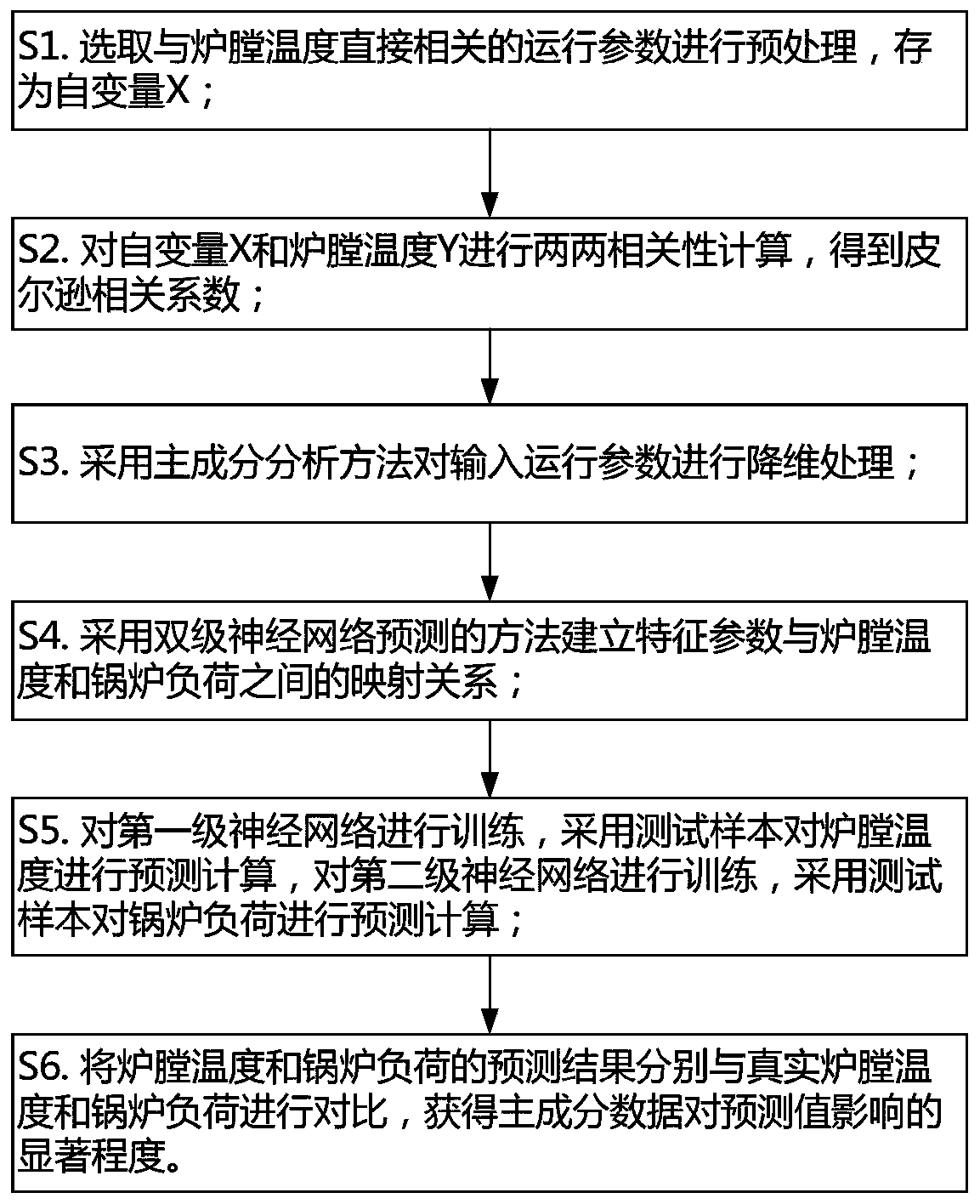

[0021] In order to realize the above technical solutions, such as figure 1 The shown embodiment is a method for predicting the furnace temperature and load of a biomass boiler, and the basic steps include: .

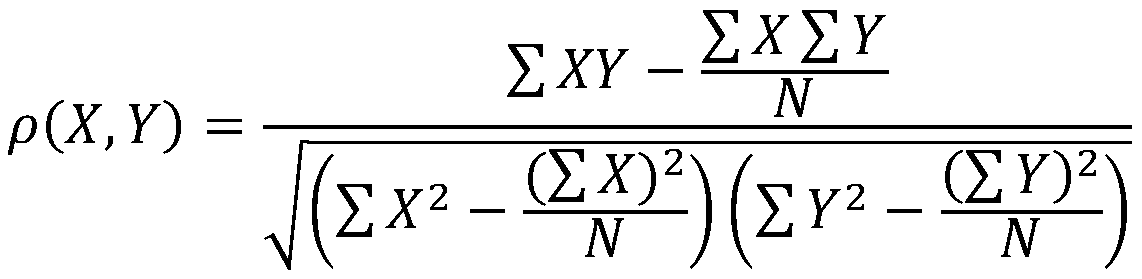

[0022] S1. Select the operating parameters directly related to the furnace temperature for preprocessing, and save it as an indepen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com