Plasma ignition and combustion-supporting combustion chamber for combusting low-calorific-value gas fuel

A low calorific value gas, plasma ignition technology, applied in the combustion chamber, combustion ignition, continuous combustion chamber, etc., can solve the problems of increasing the complexity of the gas turbine system, failing to meet the requirements of energy saving, and exceeding the content of NOX, and achieving strong practicality. value, avoid the retrofit process, prevent the effect of excessive temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

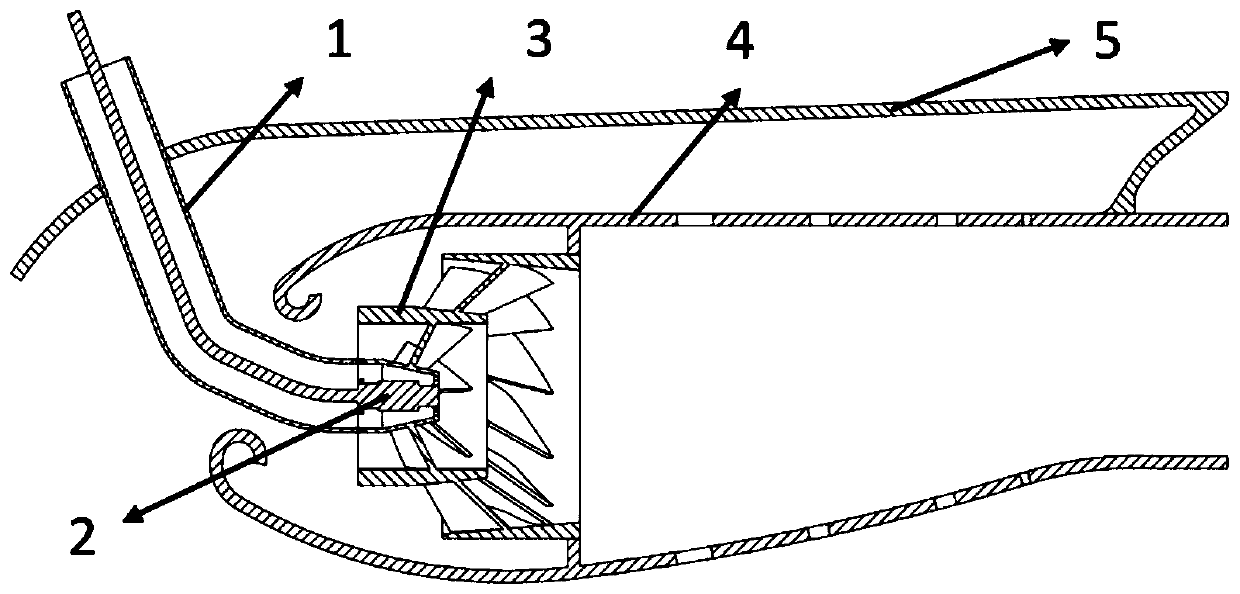

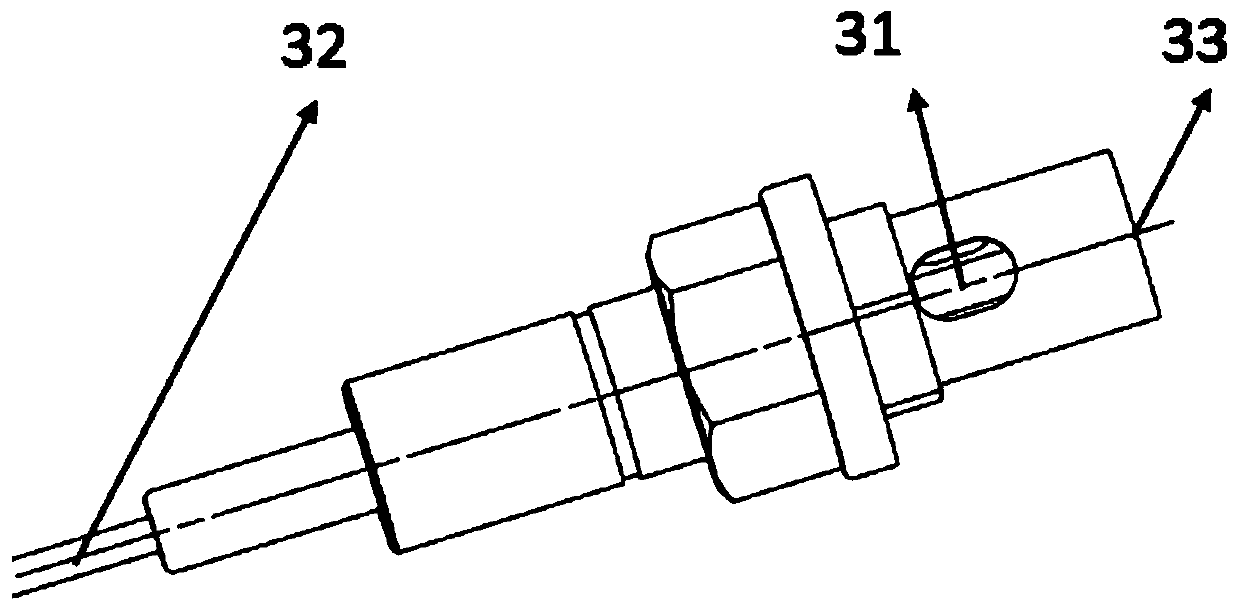

[0025] The invention relates to a plasma ignition and combustion-supporting combustion chamber for burning gas fuel with low calorific value, comprising five parts: a gas pipe, a plasma generator, a cyclone, a combustion chamber and a casing.

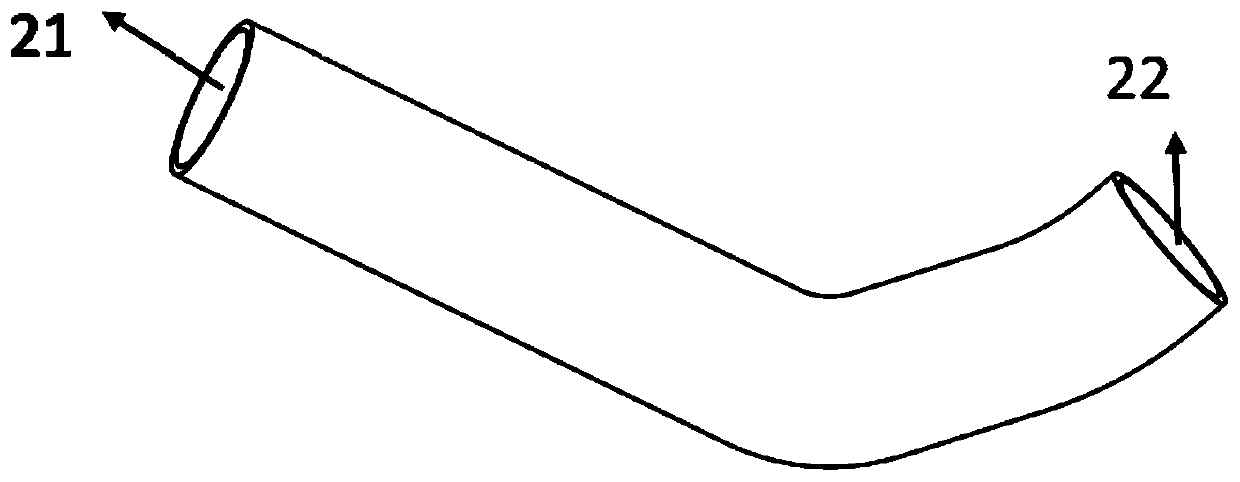

[0026] As for the gas pipe, the outlet of one end of the gas pipe is directly connected to the central pipeline of the cyclone, the inlet of the gas pipe at one end is fixed outside the casing, and the gas fuel with low calorific value can enter the central pipeline of the cyclone through the inlet of the gas pipe, and then Through the jet orifice of the central pipeline of the cyclone, it directly enters the combustion chamber for combustion, and the gas fuel with low calorific value can pass through the mixing nozzle of the central pipeline of the cyclone, and enter the primary pipeline of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com