Instant bird's nest product and production process thereof

A production process and bird's nest technology, applied in the field of instant bird's nest products and its production process, can solve the problems of unstable consistency, insufficient aroma of bird's nest, low solid content, etc., to maintain biological nutrients, improve nutrient retention rate, quality stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

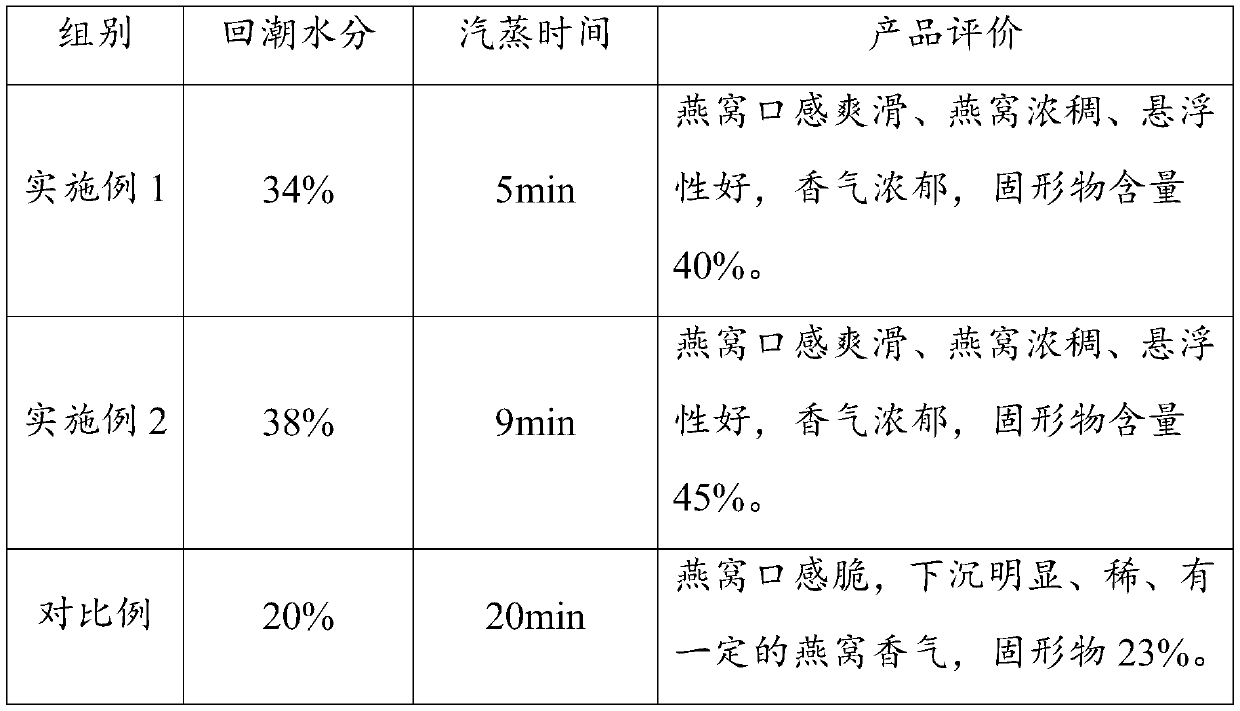

Embodiment 1

[0056] A kind of production technology of instant bird's nest product, comprises the steps:

[0057] 1) Take 1000g of bird’s nest evenly spread out on a plate, put it on the shelf in order, push it into the re-moisture room to re-moisture, the re-moisture position needs to be more than 1m away from the water mist nozzle of the ultrasonic humidifier, re-moisture for 1 hour, and weigh 1515g, after calculation, it can be known that after the bird’s nest re-moisture Moisture is 34%, spare;

[0058] 2) Spread the bird’s nest flat on the steaming tray, open the steaming cabinet, start timing when the steaming temperature is 85°C, and steam for 5 minutes to obtain the dried bird’s nest;

[0059] 3) Soak the dried bird’s nest product in purified water at 0°C for 10 hours. When the hair growth rate of the dried bird’s nest product is 4.6 times, pick the soaked bird’s nest to remove impurities, and use tweezers to gently remove the bird’s nest, eggshell, etc. Removal of impurities and ...

Embodiment 2

[0063] A kind of production technology of instant bird's nest product, comprises the steps:

[0064] 1) Take 1000g of bird’s nest evenly spread out, put it on the shelf in order, push it into the re-moisture room to re-moisture, the re-moisture position needs to be more than 1m away from the water mist nozzle of the ultrasonic humidifier, re-moisture for 1.5h, and weigh 1613g, and the calculation shows that the bird’s nest has re-moisture After the water is 38%, spare;

[0065] 2) Spread the bird's nest flat on the steaming tray, open the steaming cabinet, start timing when the steaming temperature is 85°C, and steam for 9 minutes to obtain the dried bird's nest;

[0066] 3) Soak the dried bird’s nest product in purified water at 0°C for 10 hours. When the hair growth rate of the dried bird’s nest product is 4.4 times, pick the soaked bird’s nest to remove impurities, and use tweezers to gently remove the bird’s nest, eggshell, etc. Removal of impurities and foreign matter; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com