Poultry assembly line neck-cutting tooth cutter production technology

A production process and assembly line technology, which is applied in the production process of poultry assembly line neck cutting knives, can solve the problems of reducing the service life of the knives, damaging the knives, difficult cutting, etc., and achieves the effect of strong cutting force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

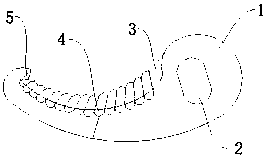

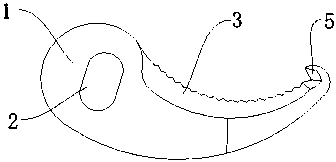

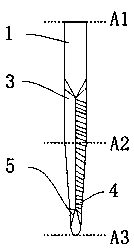

[0029] A poultry assembly line neck-cutting knife production process, including a cutting knife body 1, the cutting knife body 1 is crescent-shaped as a whole, and the right end of the cutting knife body 1 is circular, and the right end of the cutting knife body 1 is provided with a tool for processing and cutting positioning The auxiliary hole 2 of the cutting knife body 1 is fishhook-shaped at the left end, and the inner arc edge of the crescent-shaped cutting knife body 1 is machined to form a blade 3 on both sides. 4. The cross-section of the cutting alveolar 4 is semicircular arc-shaped, and the inner sides of the fishhook-shaped left end of the cutting knife body 1 are processed to form a hook blade 5. For the convenience of explanation, we have made auxiliary lines A1, A2 and A3 in the drawings of the specification , the thickness of the cutter body from the auxiliary line A2 to the auxiliary line A1 is the same, and the thickness of the cutter body from the auxiliary li...

Embodiment 2

[0040] A poultry assembly line neck-cutting knife production process, including a cutting knife body 1, the cutting knife body 1 is crescent-shaped as a whole, and the right end of the cutting knife body 1 is circular, and the right end of the cutting knife body 1 is provided with a tool for processing and cutting positioning The auxiliary hole 2 of the cutting knife body 1 is fishhook-shaped at the left end, and the inner arc edge of the crescent-shaped cutting knife body 1 is machined to form a blade 3 on both sides. 4. The cross-section of the cutting alveolar 4 is semicircular arc-shaped, and the inner sides of the fishhook-shaped left end of the cutting knife body 1 are processed to form a hook blade 5. For the convenience of explanation, we have made auxiliary lines A1, A2 and A3 in the drawings of the specification , the thickness of the cutter body from the auxiliary line A2 to the auxiliary line A1 is the same, and the thickness of the cutter body from the auxiliary li...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com