An automatic flexible mirror image clamping and damping device for CNC machine tools

A technology of CNC machine tools and clamping devices, which is applied in positioning devices, clamping, metal processing mechanical parts, etc., can solve the problems of rigid tooling and other problems such as poor versatility, and achieve the effect of fast clamping and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with accompanying drawing, the present invention is described in more detail.

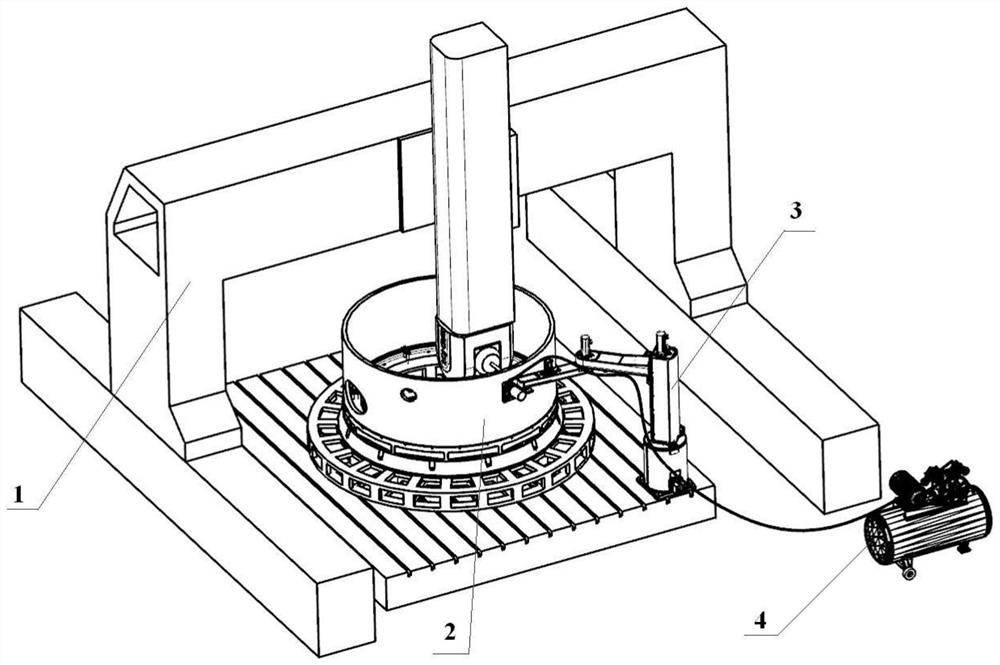

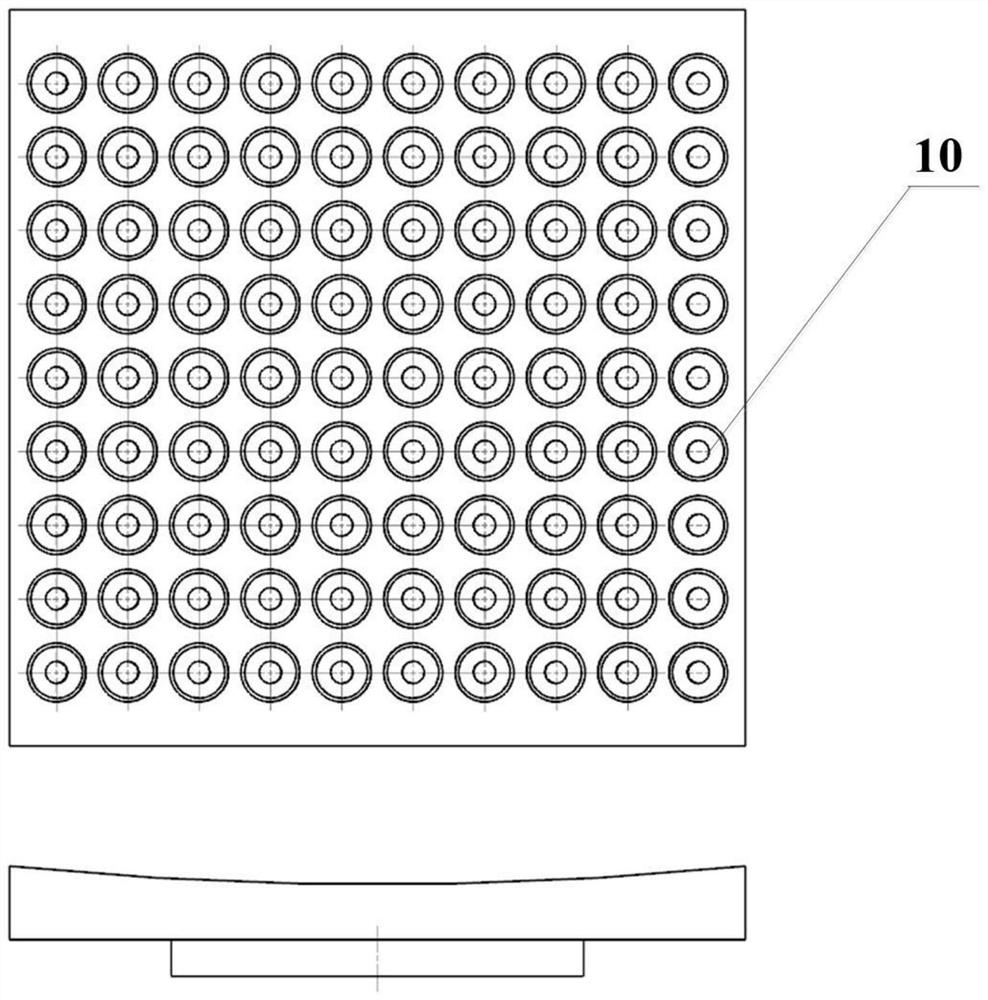

[0019] An automatic flexible mirror image clamping and damping device for a numerically controlled machine tool, comprising an automatic positioning device and a quick clamping device.

[0020] The automatic positioning device includes a machine tool coordinate data acquisition and analysis system, a robot and its control system.

[0021] Its working principle and process are:

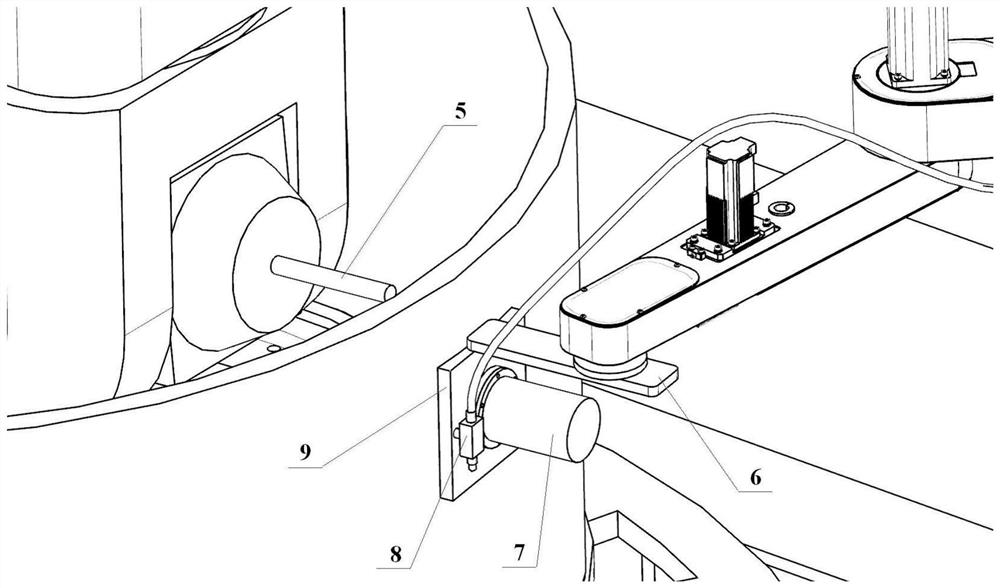

[0022] 1) The processing cutting tool 5 of the CNC machine tool 1 is positioned to the processing position of the workpiece 2;

[0023] 2) The data acquisition and analysis system pre-reads the content of the NC machining program to obtain the coordinate points of the machining position;

[0024] 3) The data acquisition and analysis system performs the mirror image transformation of the coordinates of the processing position to obtain the coordinate point of the optimal action position of the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com