A control cabinet for a collaborative robot

A technology for control cabinets and robots, applied in manipulators, manufacturing tools, etc., can solve the problems of difficult replacement of fan filters, inconvenient installation and maintenance, signal interference, etc., achieve good anti-electromagnetic interference characteristics, good anti-electromagnetic interference performance, and improve The effect of anti-interference ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

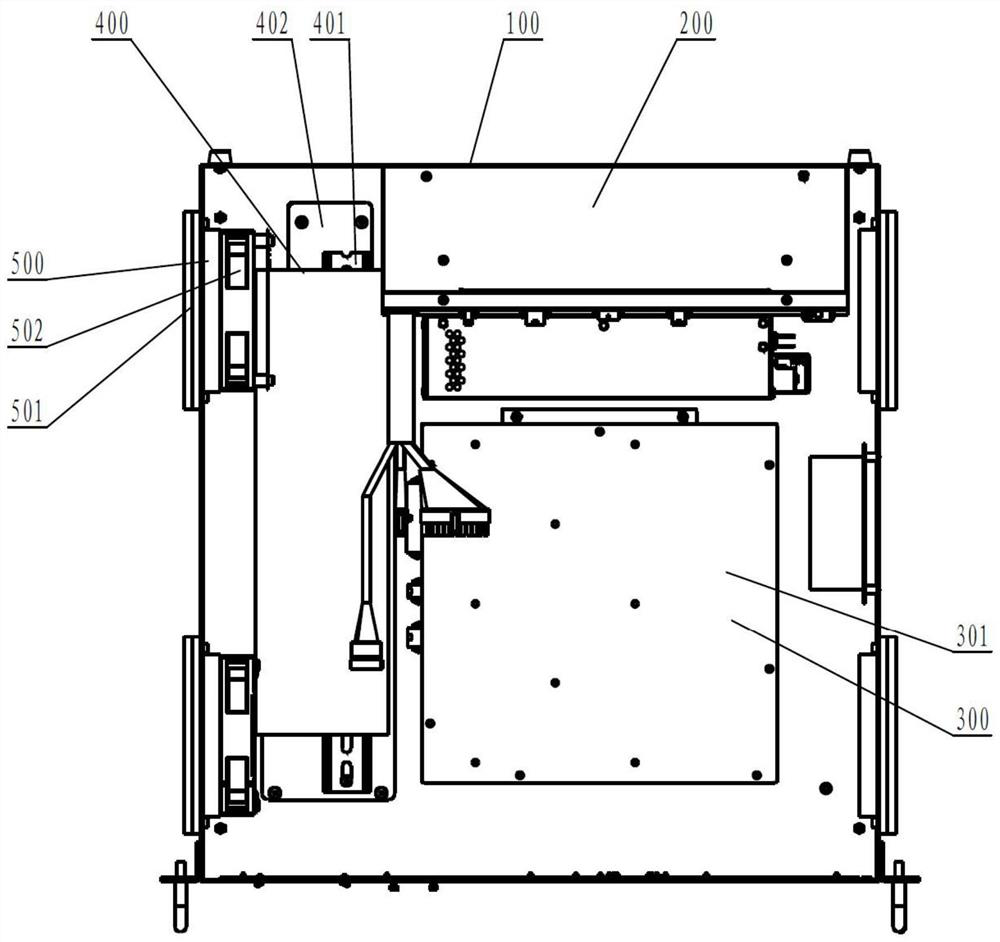

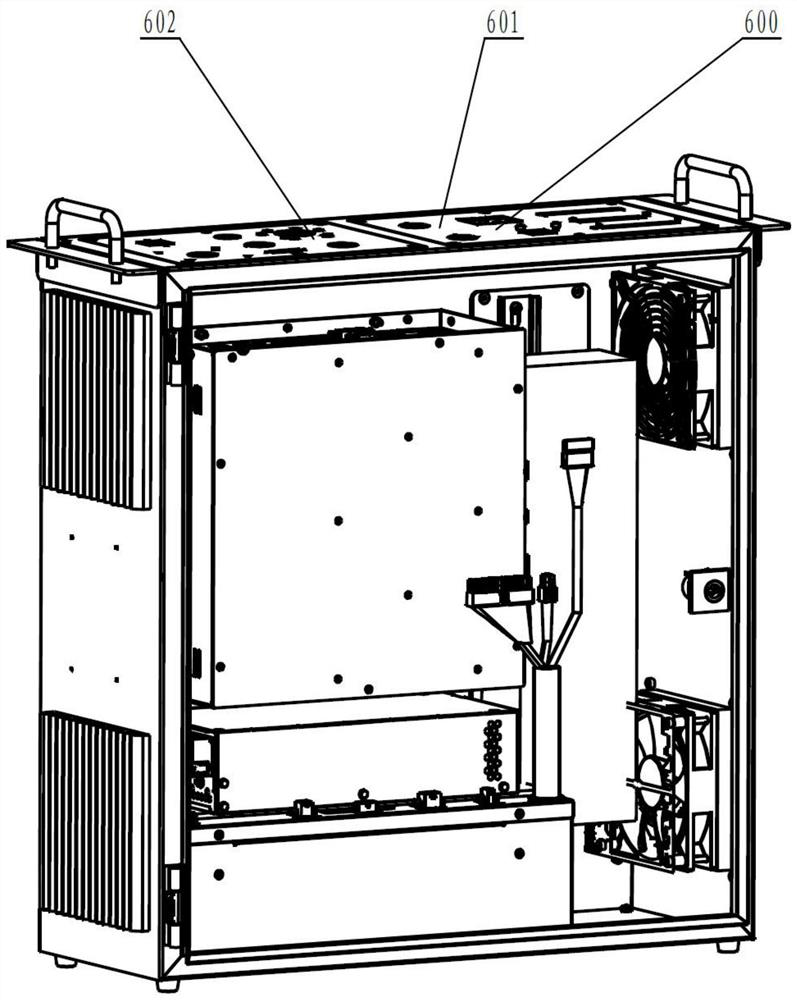

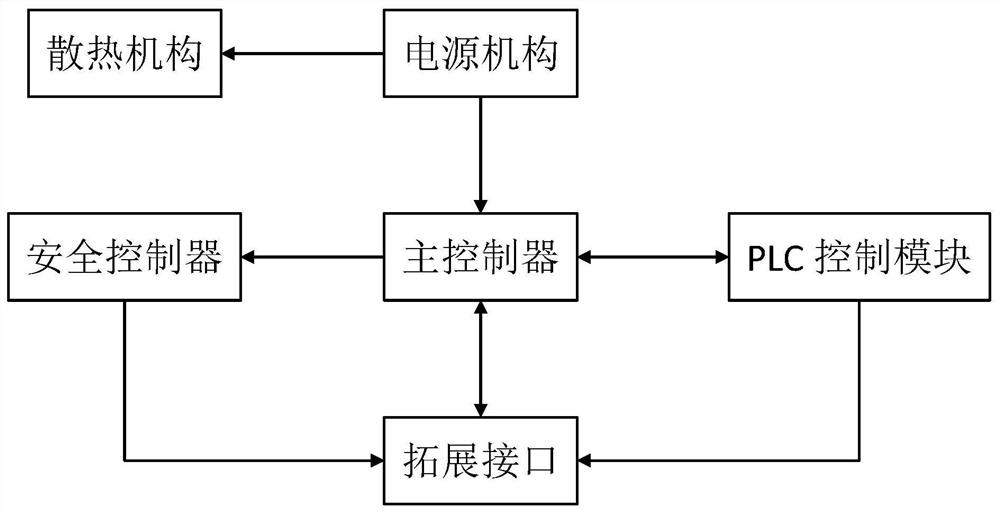

[0051] Refer to attached Figure 1-4 , a control cabinet for collaborative robots, including a cabinet body 100, the improvement of which is: it also includes a power supply mechanism 200 installed in the cabinet body 100, a main controller 300, a heat dissipation mechanism 500, and an expansion panel 600;

[0052] The power supply mechanism 200 is composed of two power supply modules, which are mechanically packaged externally, and are used to provide control power and power supply for the power supply system;

[0053] The main controller 300 is mechanically packaged externally, and is used to control the power output of each module according to the power-on sequence of the robot system;

[0054] The expansion panel 600 is provided with a plurality of expansion interfaces, and the expansion interfaces are interfaces for power supply and communication connection between the control cabinet and the collaborative robot;

[0055] The heat dissipation mechanism 500 is connected t...

Embodiment 2

[0060]On the basis of Embodiment 1, a PLC control module connected to the main controller 300 is also included, and the PLC control module is used to realize communication control and signal input and output of the collaborative robot.

Embodiment 3

[0062] On the basis of Embodiment 2, the PLC control module includes a PLC coupler, a common DI module, a common DO module, an EtherCat communication module, and an RS485 communication module.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com