Woodworking industrial processing rapid edge trimming device

It is an industrial and woodworking technology, which is applied in the field of fast edge lifting device in woodworking industry, which can solve the problems of poor adjustment function, low efficiency, and high degree of manual participation, and achieve the effect of high work efficiency, high positioning accuracy, and half operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

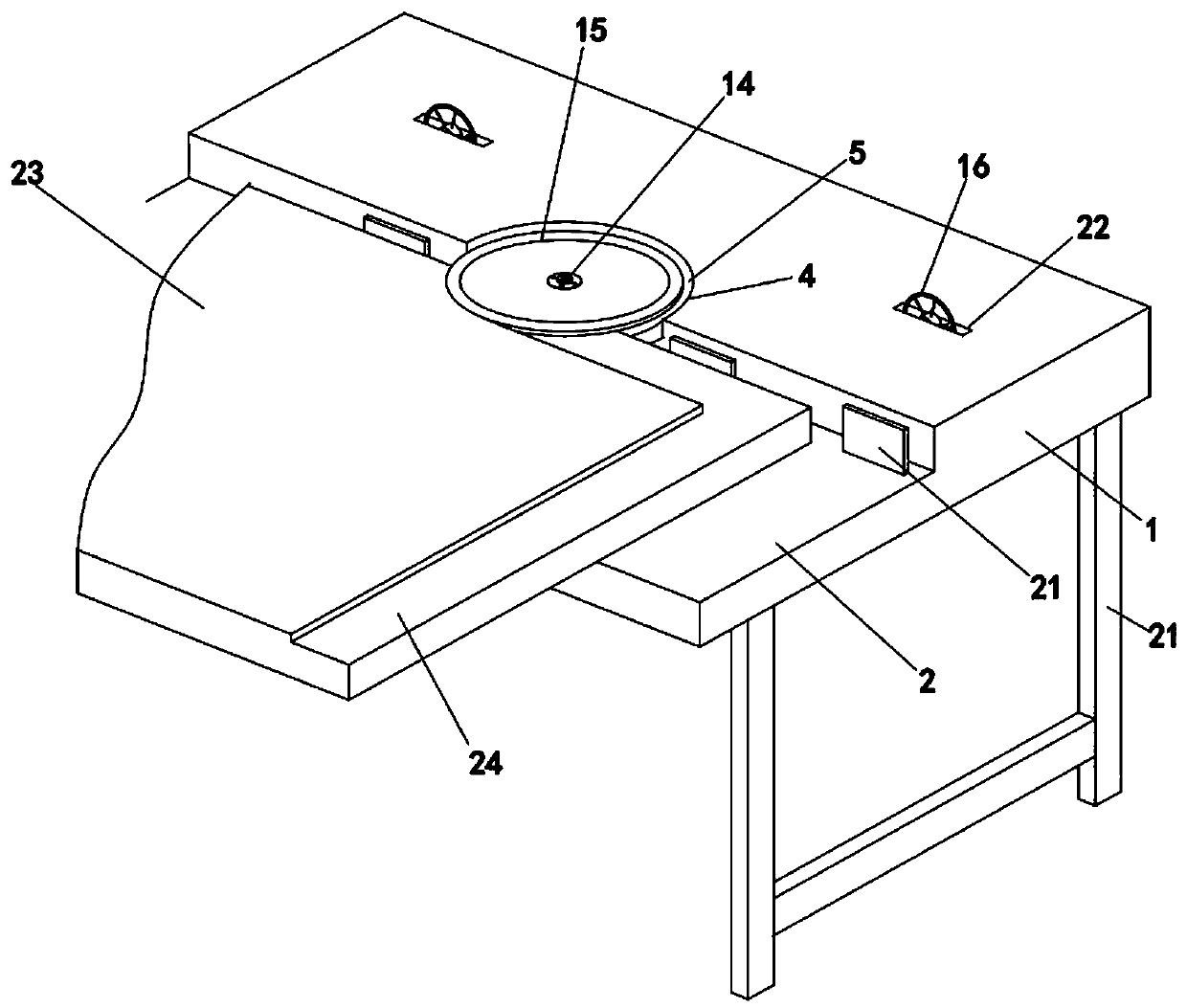

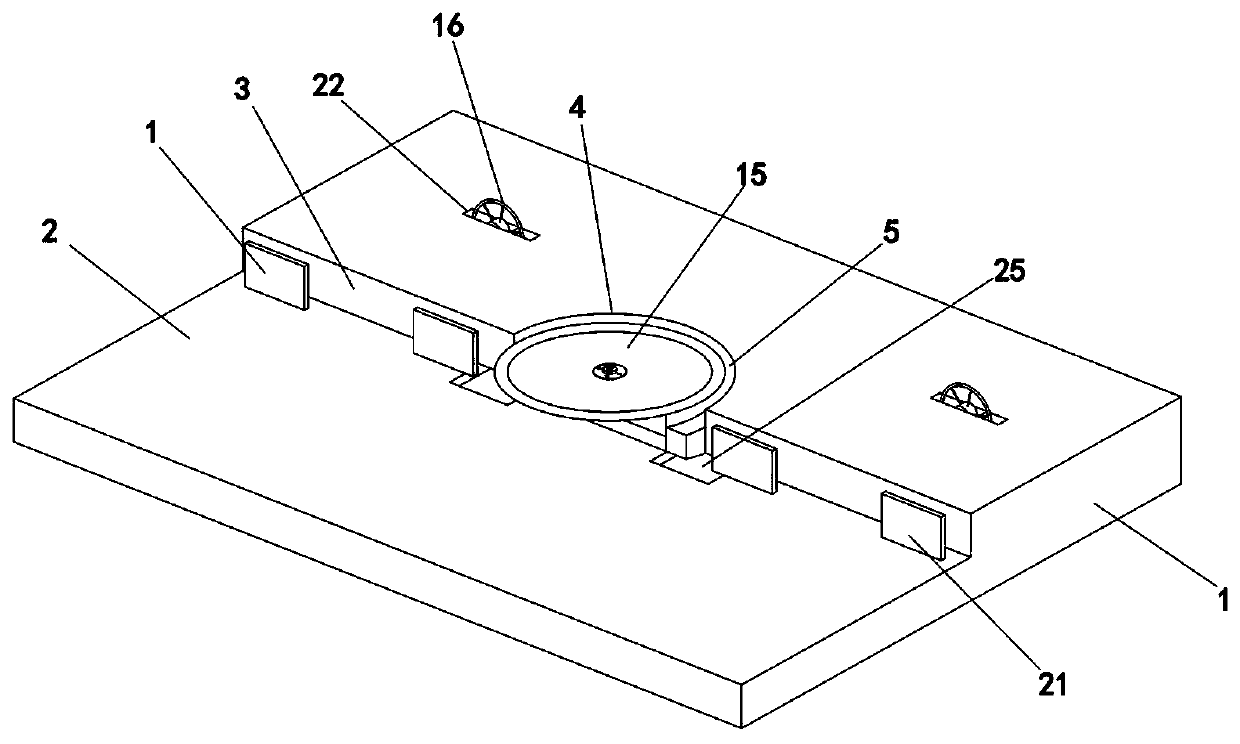

[0019] Embodiment 1: a kind of simple in structure but practical high-efficiency carpentry trimming device, such as figure 1 and figure 2 As shown, the device includes components such as a support 27, a workbench 1, and a chainsaw mechanism. Specific as figure 2 Among them, the workbench 1 includes a support platform 2 on the front side and an adjustment area on the rear side. The support platform 2 on the front side is a plane platform for carrying the plate 23. There are basically no accessories on the surface of the plane platform, but the plane platform can expand outward along the width direction to meet the processing requirements for plates 23 of different widths.

[0020] figure 2 It can be seen that the upper surface of the adjustment area is higher than the support platform 2, and there is a support facade 3 between the two. The upper side of the adjustment area is not an area for processing, and auxiliary parts and adjustment parts can be arranged. It can be...

Embodiment 2

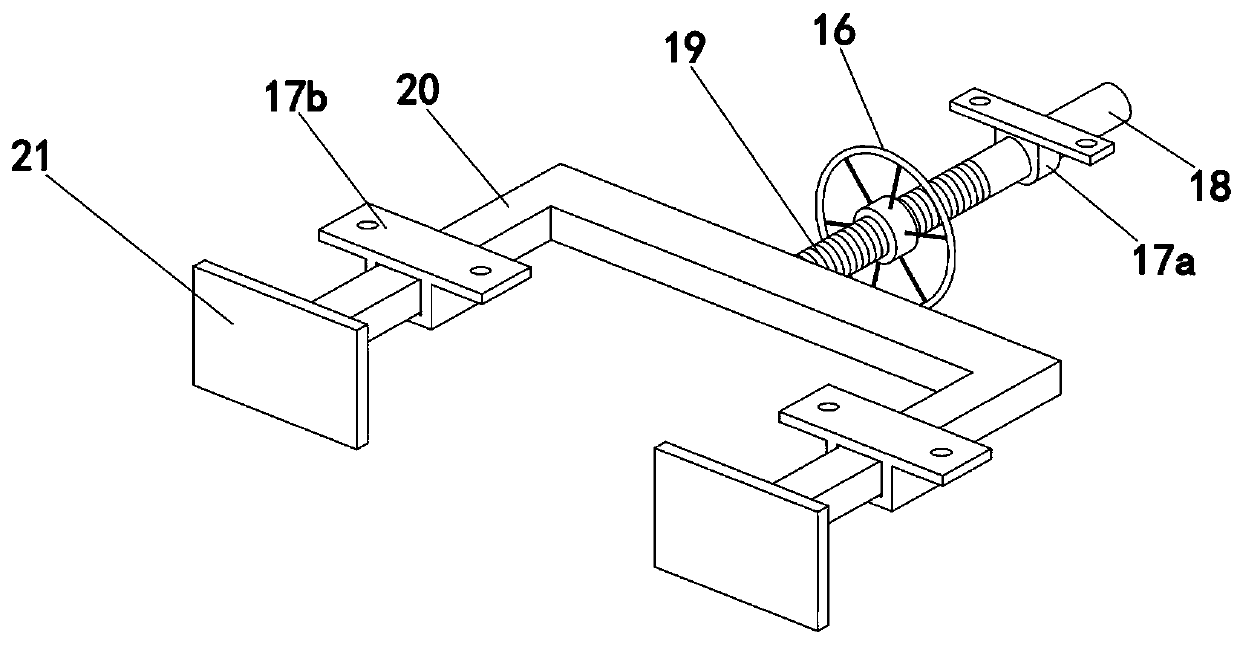

[0025] Embodiment 2: as Figure 4-6 Shown, on the basis of embodiment 1, by Figure 6 It can be seen that an assembly hole is provided in the center of the semicircular support base 5 and a matching lifting sleeve 7 is provided. The bottom of the lifting sleeve 7 is fixed with a motor 8, and the rotating shaft 9 of the motor 8 is installed on the shaft of the lifting sleeve 7 through a bearing 10. In the center hole, after the rotating shaft 9 of the motor 8 passes through the center hole, a horizontal circular saw blade 15 is fixed through the saw blade fixing part 14. Half of the saw teeth on the edge of the circular saw blade 15 are located in the semi-circular groove, and the other Half of the protrusion is located on the support platform 2 upper side.

[0026] A groove is arranged at the center of the upper part of the semicircular support seat 5, and the lifting support 6 is fixed on the upper end of the lifting sliding sleeve 7, and the lifting support 6 is matched and...

Embodiment 3

[0027] Embodiment 3: On the basis of Embodiment 1 or 2, the support platform is set as two support platforms, the rear support platform 2a and the front support platform 2b respectively, and the front and rear support platforms respectively include protruding support bodies and the groove between the adjacent support body, the rear support platform 2a and the front support platform 2b are successively matched with each other by convex and concave, such as Figure 7 shown. In addition, the bracket 27 includes a rear leg 27a and a front leg 27b, the rear leg 27a is vertically connected with a rear connection pipe 28a, the front leg 27b is vertically connected with a front connection pipe 28b, and the rear connection pipe 28a is connected to the front connection pipe 28b. After the suit is fixedly connected by locking wire 29. The rear support platform is fixed on the upper end of the rear outrigger, and the front support platform is fixed on the upper end of the front outrigger...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com