Large sheet shaving gluing and inflaming retarding device

A technology of shavings and large pieces, which is applied in the field of sizing devices for large shavings, can solve problems such as uneven sizing and fast falling speed, and achieve the effects of reducing application processes, saving equipment costs, and streamlining production processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

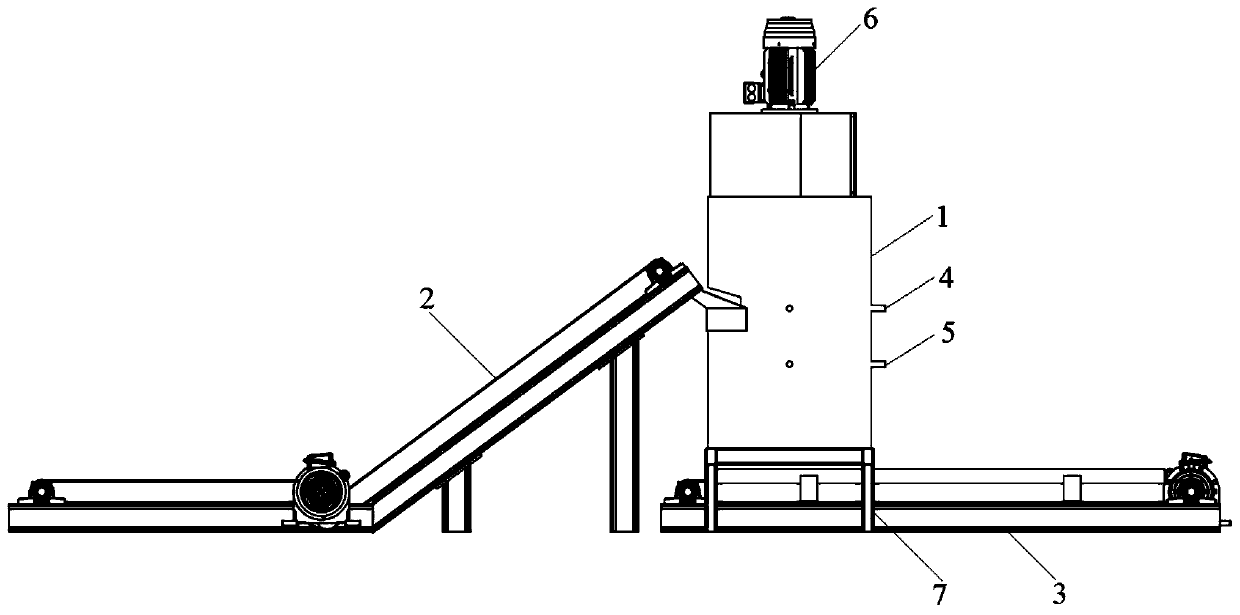

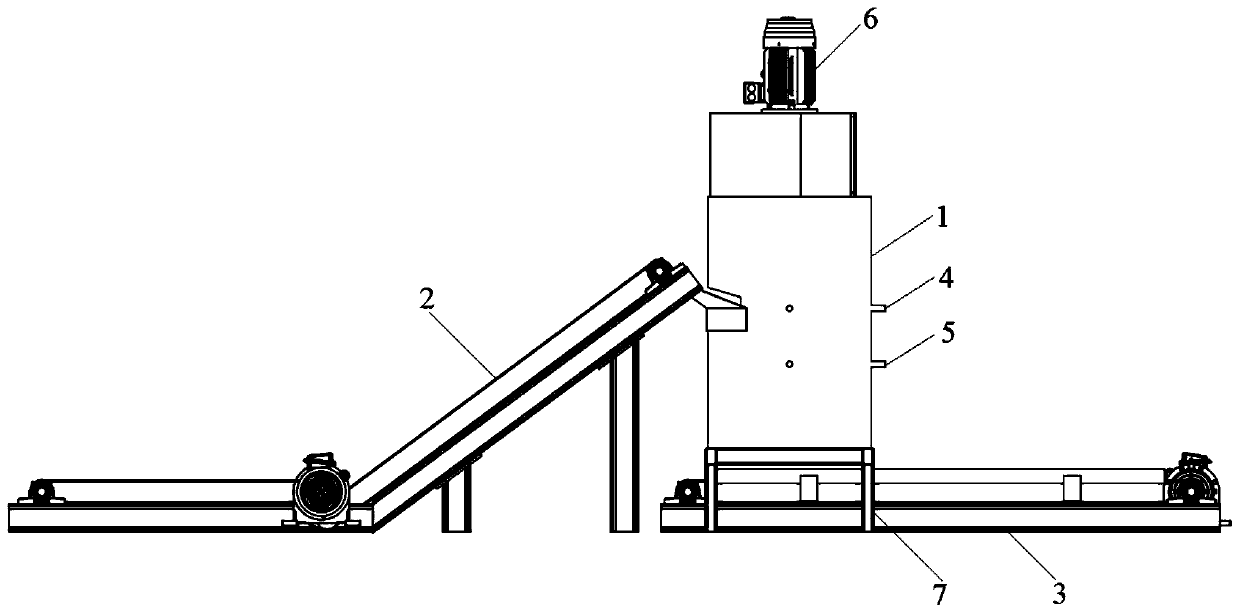

[0024] first embodiment ,refer to figure 1 and 2 , an example of a fire retardant device for sizing large flakes of the present invention, including: a housing 1, a first conveying device 2, a second conveying device 3, a flame retardant nozzle 4, an adhesive nozzle 5 and a centrifugal fan 6 ; Wherein: the housing 1 is a cylindrical structure with a chamber, the upper part of the side wall of the housing 1 is provided with a feed port, and the bottom of the housing 1 is provided with a discharge port; the first conveying device 2 is provided with The raw material is transported to the material inlet; the second conveying device 3 is arranged below the material outlet; the first conveying device 2 is supported by a bracket and extends to the material inlet. The flame retardant nozzle 4 and the adhesive nozzle 5 are all arranged on the side wall of the housing 1 and are located on the opposite side of the feed inlet; the centrifugal fan 6 is arranged on the top wall of the ho...

no. 2 example

[0026] second embodiment , the large flakes sizing flame retardant device also includes a base 7, the housing 1 is installed on a bracket, and the bracket supports the housing 1 at a certain height from the ground, so as to be installed under the discharge port of the housing Second delivery device.

no. 3 example

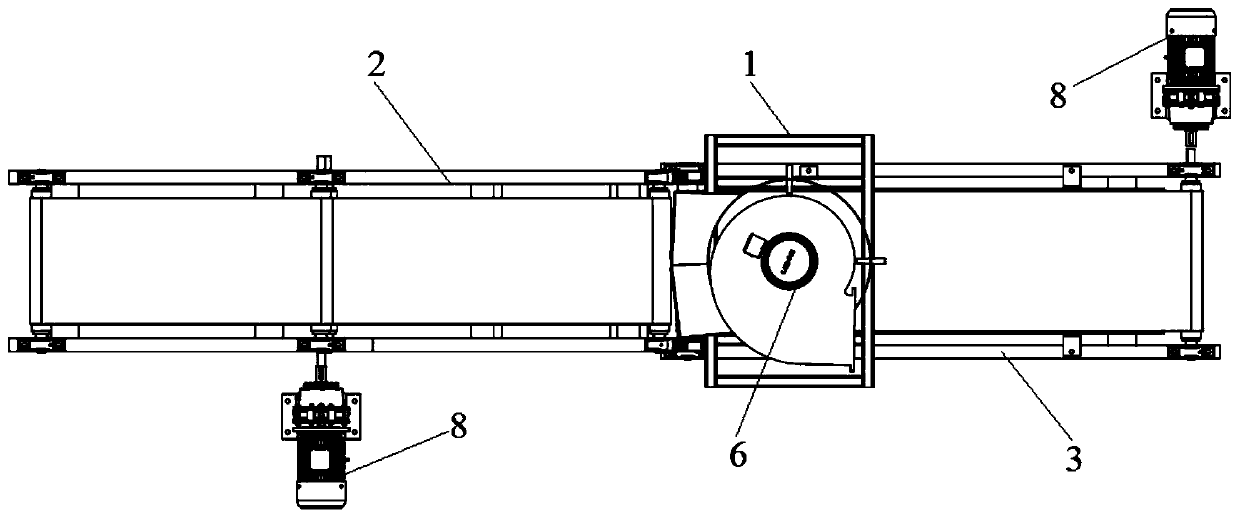

[0027] third embodiment ,refer to figure 2 , the first conveying device 2 and the second conveying device 3 are conveyor belts driven by a motor 8, through the first conveying device 2, a large piece of thin shavings are sent from the feed port into the housing chamber, after sizing and applying flame retardant After the agent is added, it is transported out from the discharge port at the bottom of the shell and enters the next process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com