Cement gypsum-based straw light-weight wall heat-insulation board and preparation method thereof

A lightweight wall, gypsum-based technology, applied in the field of building materials, can solve problems such as low strength, achieve excellent thermal insulation performance, high strength, and reduce environmental pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

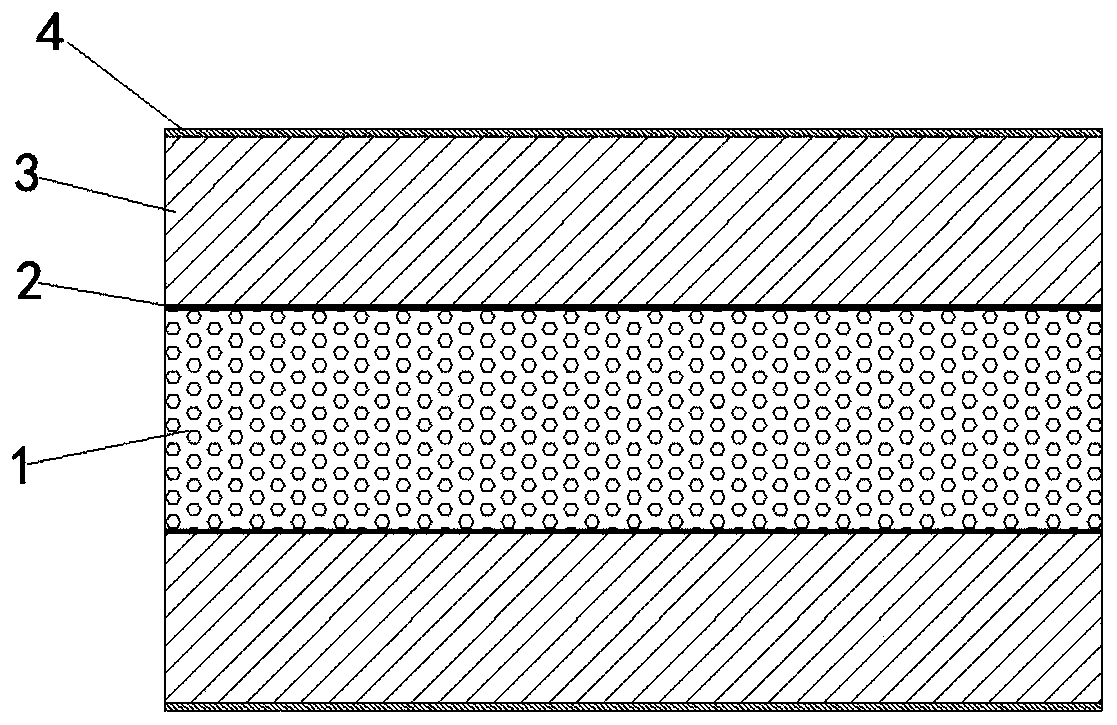

[0033]A cement gypsum-based straw lightweight wall insulation board, comprising a low-density cement gypsum-based straw inner lining board 1, glass fiber mesh cloth 2, a high-density cement gypsum-based straw outer panel 3, and a cement gypsum protective layer 4. The front and rear sides of the cement gypsum-based straw lining board 1 are glued with glass fiber mesh cloth 2, and the outer layer of the glass fiber mesh cloth 2 is equipped with a high-density cement gypsum-based straw outer panel 3, and a high-density cement gypsum-based straw outer panel 3. A cement plaster protective layer 4 is provided on the outside. The thickness of the high-density cement gypsum-based straw outer panel 3 is 5 cm; the thickness of the low-density cement gypsum-based straw inner liner 1 is 7 cm; the thickness of the glass fiber mesh cloth 2 is 2.5 mm; the thickness of the cement gypsum protective layer 4 is 0.8 cm.

[0034] The preparation method of the cement gypsum-based straw lightweight...

Embodiment 2

[0043] A cement gypsum-based straw lightweight wall insulation board, comprising a low-density cement gypsum-based straw inner lining board 1, glass fiber mesh cloth 2, a high-density cement gypsum-based straw outer panel 3, and a cement gypsum protective layer 4. The front and rear sides of the cement gypsum-based straw lining board 1 are glued with glass fiber mesh cloth 2, and the outer layer of the glass fiber mesh cloth 2 is equipped with a high-density cement gypsum-based straw outer panel 3, and a high-density cement gypsum-based straw outer panel 3. A cement plaster protective layer 4 is provided on the outside. The thickness of the high-density cement gypsum-based straw outer panel 3 is 4 cm; the thickness of the low-density cement gypsum-based straw inner liner 1 is 6 cm; the thickness of the glass fiber mesh cloth 2 is 3 mm; the thickness of the cement gypsum protective layer 4 is 1 cm.

[0044] The preparation method of the cement gypsum-based straw lightweight wal...

Embodiment 3

[0053] A cement gypsum-based straw lightweight wall insulation board, comprising a low-density cement gypsum-based straw inner lining board 1, glass fiber mesh cloth 2, a high-density cement gypsum-based straw outer panel 3, and a cement gypsum protective layer 4. The front and rear sides of the cement gypsum-based straw lining board 1 are glued with glass fiber mesh cloth 2, and the outer layer of the glass fiber mesh cloth 2 is equipped with a high-density cement gypsum-based straw outer panel 3, and a high-density cement gypsum-based straw outer panel 3. A cement plaster protective layer 4 is provided on the outside. The thickness of the high-density cement gypsum-based straw outer panel 3 is 7cm; the thickness of the low-density cement gypsum-based straw inner liner 1 is 8cm; the thickness of the glass fiber mesh cloth 2 is 2mm; the thickness of the cement gypsum protective layer 4 is 0.8cm .

[0054] The preparation method of the cement gypsum-based straw lightweight wal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com