Bottle blowing machine with limiting assembly

A limit component and blow molding machine technology, applied in the field of plastic processing, can solve the problems of raw material cost and transportation cost increase, large installation space, opening and closing mold structure reservation, etc., to reduce raw material cost and transportation cost, simplify assembly The difficulty of maintenance and the effect of reducing maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] This embodiment provides a bottle blowing machine with a limit assembly.

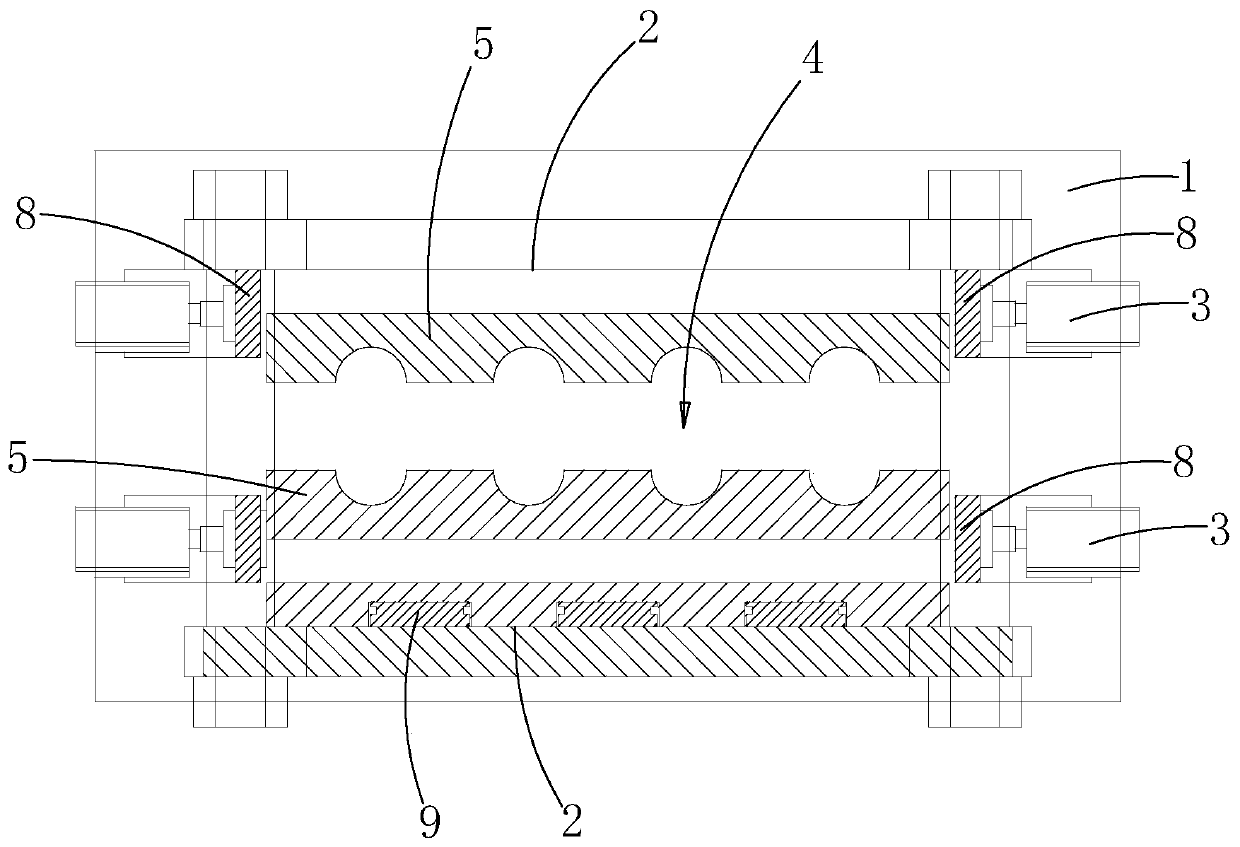

[0034] like figure 1 The bottle blowing machine shown is composed of a frame 1 and a conveying mechanism, a heating mechanism, and a bottle blowing mechanism arranged on the frame 1. The bottle blowing mechanism includes a mold opening and closing structure and a blowing structure, and the mold opening and closing The structure includes a limiting working surface 2 with two axes parallel to each other, and a limiting component 3 and a mold component 4 separated along the axial direction are interposed between the limiting working surfaces 2, and the mold component 4 is formed by opening the mold When the station is axially closed to the mold clamping station, the limit assembly 3 moves from the idle station that is misaligned with the axial projection of the mold assembly 4 to the clamping station that coincides with the axial direction of the mold assembly 4, so that the limit working surface 2...

Embodiment 2

[0041] Compared with the first embodiment, this embodiment provides a specific blow molding machine structure.

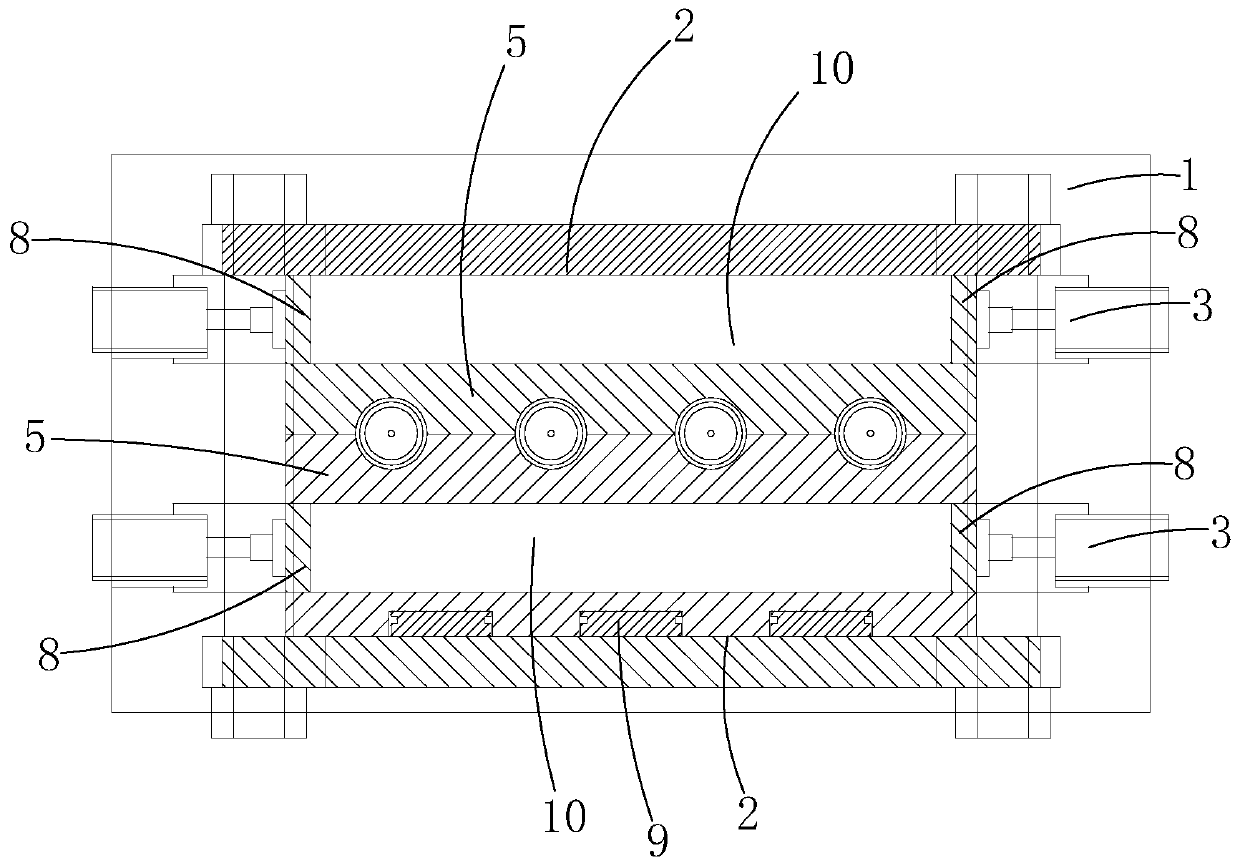

[0042] like figure 2 As shown, the mold assembly 4 includes two mold plates 5 that are arranged in parallel and can be opened and closed in the axial direction. An active space 10 for the axial displacement of the die plate 5 is formed between the limit working surfaces 2 . The film grooves are provided on the facing surfaces of the mold plates 5, so that the mold plates 5 can form a mold cavity for blowing the bottle body by facing each other. When in use, when the limit assembly 3 is switched from the clamping position to the idle position, an active space 10 is formed on the back of the mold plate 5 for its axial movement and opening, and no structure is arranged in the active space 10 , to ensure that the mold plates 5 move axially smoothly, so that the mold plates 5 move back to each other and ensure that the mold assembly 4 is switched to the mold opening s...

Embodiment 3

[0062] Compared with the second embodiment, this embodiment provides another specific blow molding machine structure.

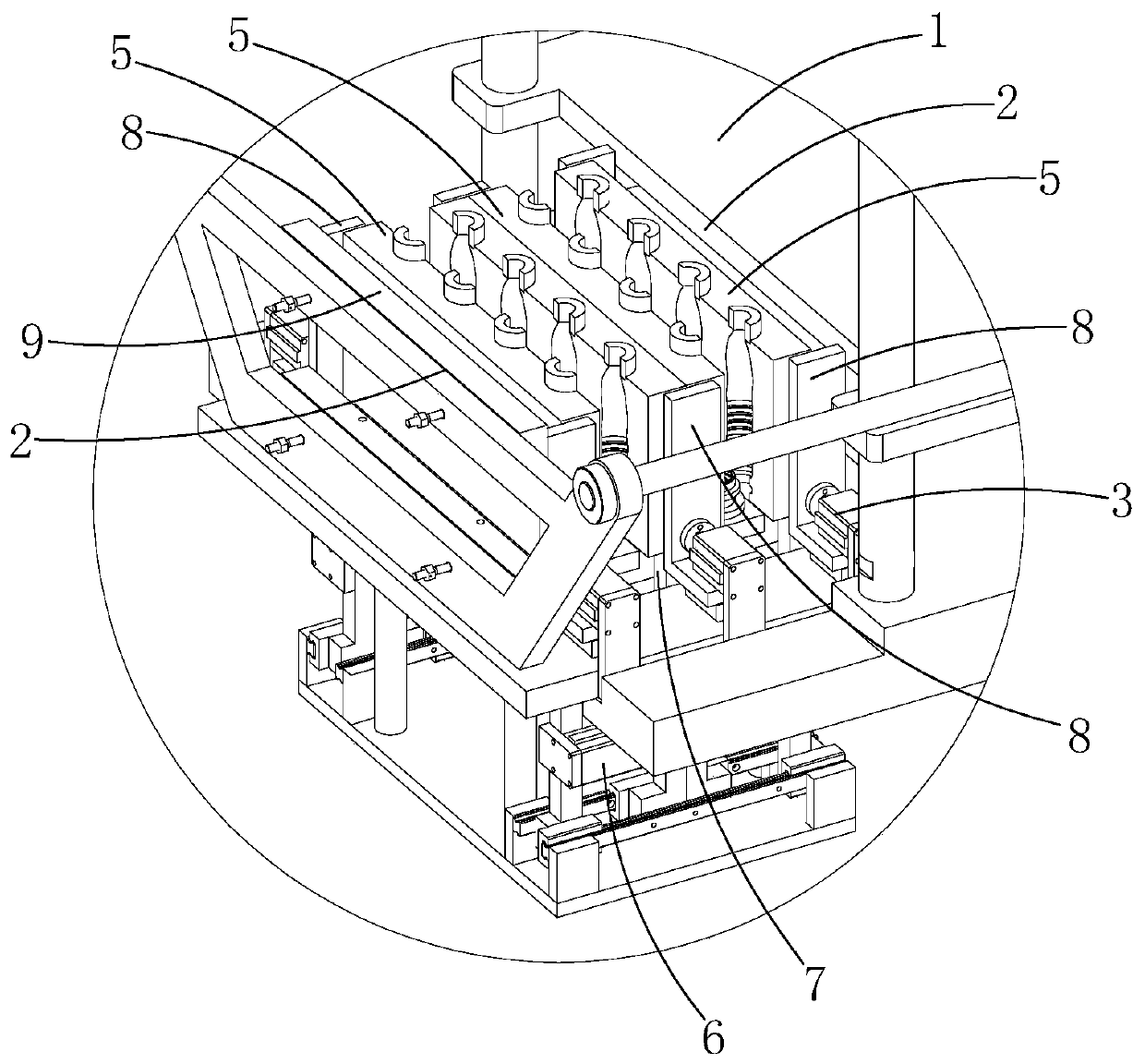

[0063] like image 3 and 4 As shown, the mold components 4 are at least two groups and are arranged at an axial distance, and a limit component 3 is provided between adjacent mold components 4, so that the limit working surface 2 axially clamps each mold component through the limit component 3 4. Specifically, the number of mold cavities is increased by increasing the number of mold components 4 between the limiting working surfaces 2, thereby increasing the number of single-mold closing and blowing bottles, effectively improving processing efficiency.

[0064] In this embodiment, when the number of mold components 4 increases, the number of said limiting components 3 will also increase accordingly, so as to ensure that each mold plate 5 has a corresponding movable space 10 . The limiting components 3 are at least two groups, and are arranged separately on...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap