Rubbing-resistant flexible composite material

A composite material and rubbing-resistant technology, which is applied in the field of composite material manufacturing, can solve problems affecting the airtightness and use of the aerostat capsule, air leakage, difficulty in finding and repairing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

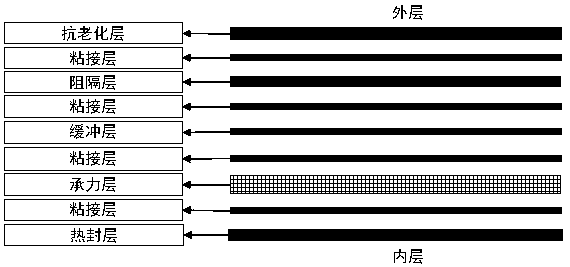

[0019] Embodiment 1: The rub-resistant flexible composite material is composed of 9 layers, which are flexible anti-aging layer, adhesive layer, barrier layer, adhesive layer, buffer layer, adhesive layer, load-bearing layer, adhesive layer from outside to inside. Tie layer and heat seal layer. The thickness of the anti-aging layer is 12-50um, and the surface density is 15-80g / m 2 ;The bonding layer density is 2~25g / m 2 ; The thickness of the barrier layer is 10-15um, and the surface density is 12-25g / m 2 ;The thickness of the buffer layer is 12~25um, and the surface density is 15~40g / m 2 ;The density of bearing layer is 60~130g / m 2 ; The surface density of the heat-sealing layer material is 15-40g / m 2 , each layer becomes an integrated and multi-functional material through the lamination composite preparation process.

specific Embodiment approach 2

[0020] Embodiment 2: This embodiment differs from Embodiment 1 in that the material of the anti-aging layer is polyvinyl fluoride (PVF) film or polyvinylidene fluoride (PVDF) film. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0021] Embodiment 3: This embodiment is different from Embodiment 1 in that the material of the barrier layer is PET film. Others are the same as in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com