A kind of method for preparing fusible ptfe

A technology of PTFE and solid materials, applied in chemical instruments and methods, chemical/physical processes, feeding devices, etc., can solve the problems of easy accumulation, inconvenient filtration, washing and drying, etc., to ensure collection, improve fluidity, reduce The effect of the bend settings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

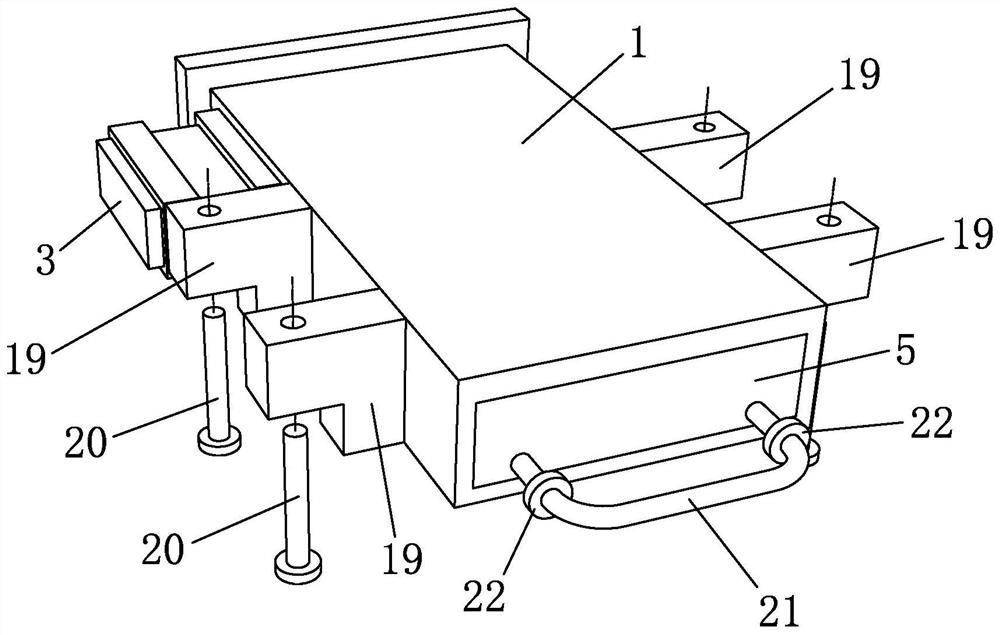

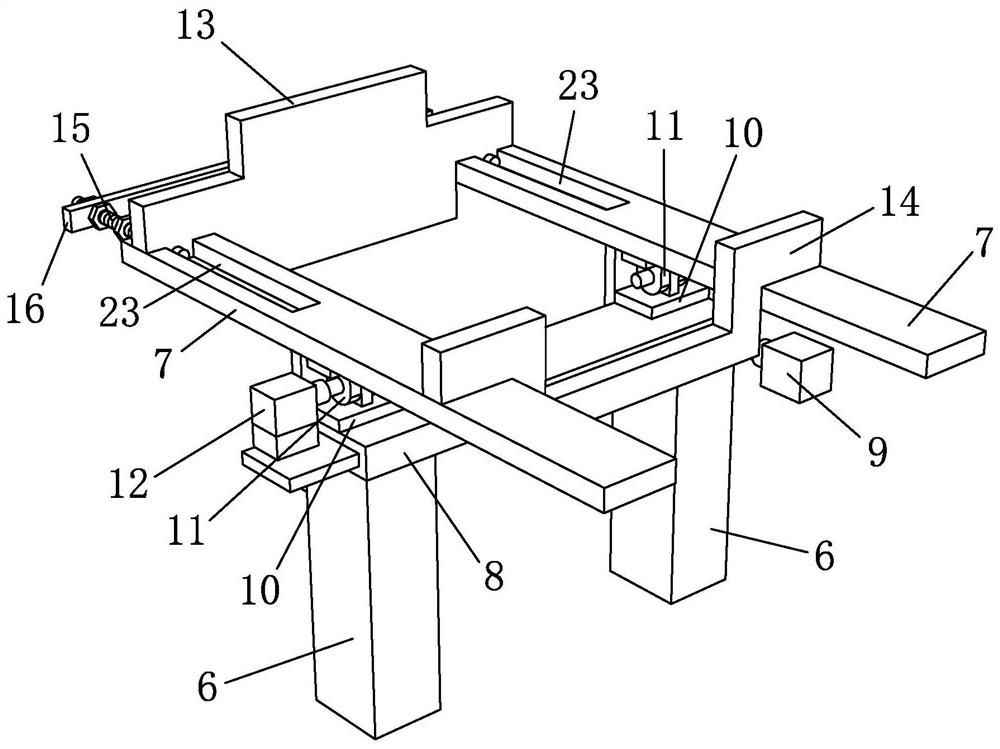

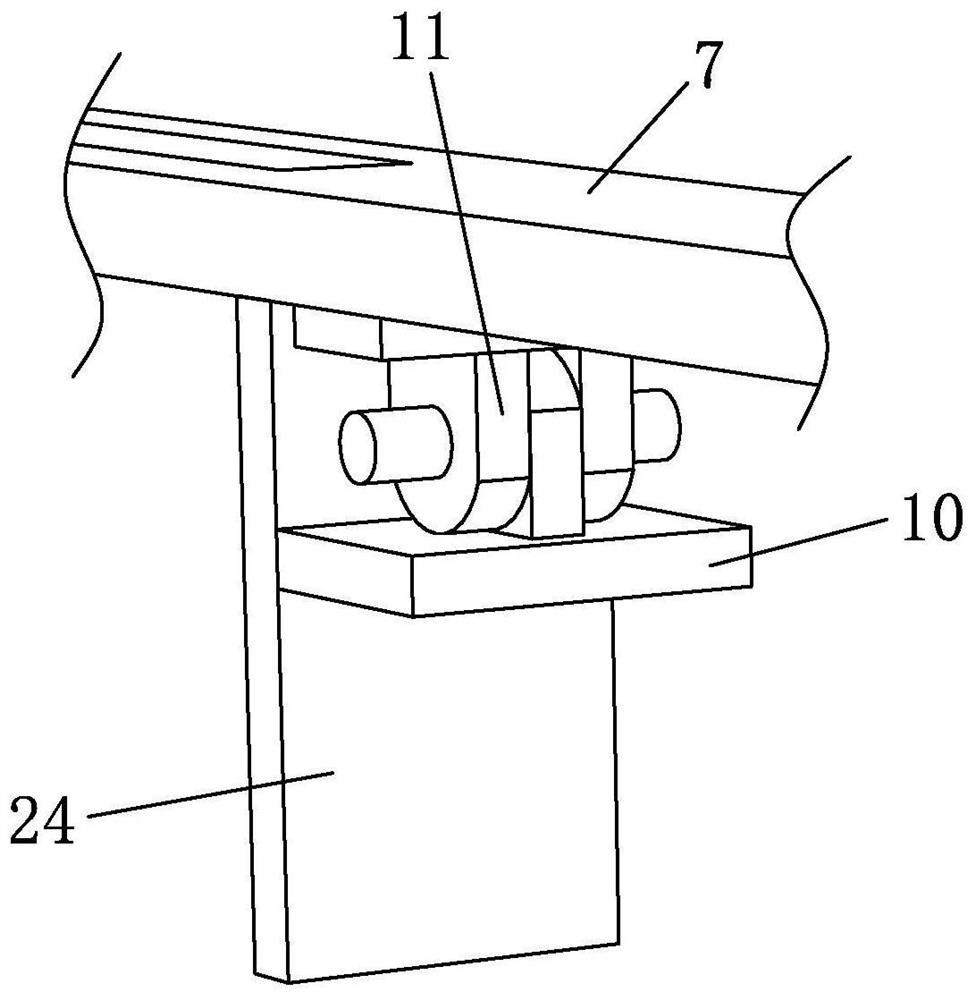

[0038] Such as Figure 1 to Figure 7 Shown, be a kind of method for preparing fusible PTFE of the present invention, comprise the steps:

[0039] a. In an oxygen-free polymerization kettle, add an initiator to the mixture of solvent, polymerizable monomer and chain transfer agent to carry out polymerization reaction, and use tetrafluoroethylene to control the pressure in the reaction environment to be constant, and use tetrafluoroethylene to control the reaction environment. The pressure is constant at 0.3-0.6MPa.

[0040] b. After tetrafluoroethylene is added to a predetermined mass, add preheated deionized water and an initiator, and the initiator is selected from ammonium persulfate, potassium persulfate, perfluoroacyl peroxide, and azobisisobutyronitrile at least one. Continue the polymerization reaction. After the deionized water and tetrafluoroethylene are added to a certain mass, stop adding tetrafluoroethylene and deionized water, and keep warm at 40°C.

[0041] c. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com