Copper surface micro-etching roughening solution and preparation method thereof

A technology of roughening liquid and copper surface, which is applied in the copper surface micro-etching roughening liquid of PCB and its preparation field, which can solve the problems such as the crystal structure of the copper surface becomes smaller, the copper surface is difficult to form roughening, and the color difference of the PCB surface. To achieve the effect of improving adhesion, good treatment effect and small difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

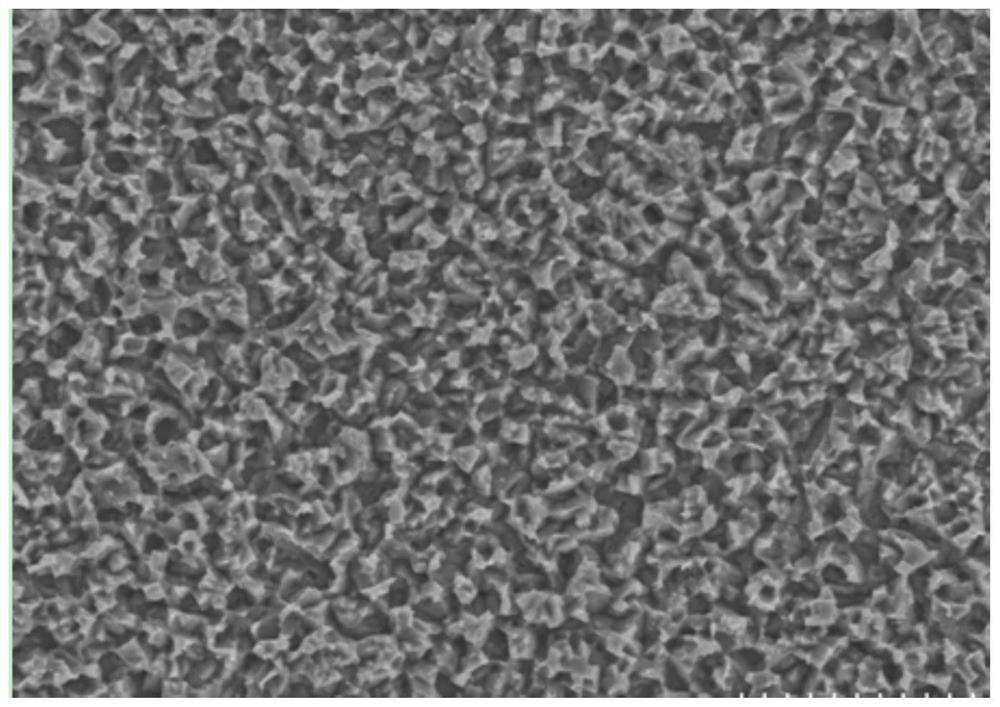

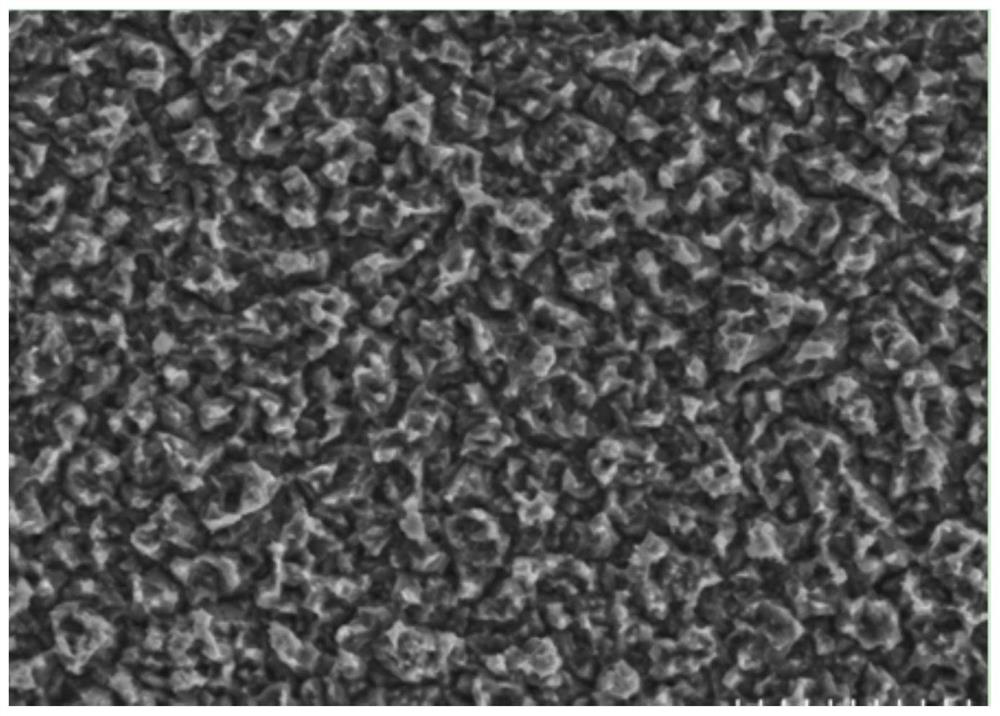

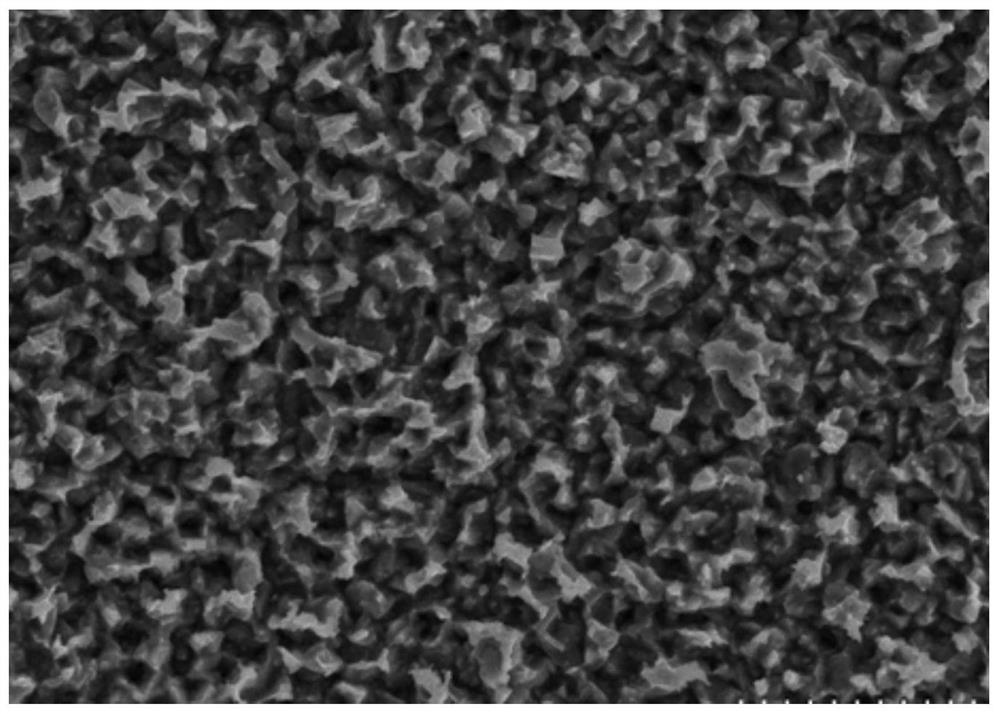

Image

Examples

preparation example Construction

[0043] A preparation method of copper surface micro-etching roughening solution, the steps are as follows:

[0044] Step 1: Weigh the copper ion source, organic acid and chloride ion source of the formula, add them in deionized water and stir to dissolve;

[0045] Step 2: Weigh the water-soluble polymer and pyridine derivative in the formula amount in the solution prepared in step 1, and stir evenly;

[0046] Step 3: Dilute the solution obtained in Step 2 to 1L with deionized water, and stir evenly to obtain the coarsening solution;

[0047] Wherein, the water-soluble polymer is self-made vinylimidazole and acrylamide copolymer, vinylimidazole and diallyl quaternary ammonium salt copolymer, vinylimidazole and vinylpyrrolidone copolymer, or vinylimidazole and formazan Acryloyloxyethyltrimethylammonium chloride copolymer.

[0048] One, embodiment and preparation method thereof

Embodiment 1

[0050] 1) Including the following components and their mass concentrations:

[0051] Malic acid 20g / L;

[0052] Divalent copper ion 5g / L, from copper bromide;

[0053] Chloride ion 5g / L, from potassium chloride;

[0054] Self-made water-soluble polymer (I) 0.0005g / L, polymer (I) adopts vinylimidazole and acrylamide copolymer, the mass content of vinylimidazole is 30%, and the mass content of acrylamide monomer is 70%;

[0055] 2-picoline 0.001g / L;

[0056] The balance of deionized water;

[0057] 2) Preparation method:

[0058] Step 1: Weigh the copper ion source, organic acid and chloride ion source of the formula, add them in deionized water and stir to dissolve;

[0059] Step 2: Weigh the water-soluble polymer and pyridine derivative in the formula amount in the solution prepared in step 1, and stir evenly;

[0060] Step 3: Dilute the solution obtained in Step 2 to 1 L with deionized water, and stir evenly to obtain the coarsening solution.

Embodiment 2

[0062] 1) Including the following components and their mass concentrations:

[0063] Citric acid 25g / L;

[0064] Divalent copper ion 10g / L, from copper formate;

[0065] Chloride ion 10g / L, from ferric chloride;

[0066] Self-made water-soluble polymer (II) 0.001g / L, polymer (II) adopts vinylimidazole and diallyl quaternary ammonium salt copolymer, vinylimidazole mass content 40%, diallyl quaternary ammonium salt monomer Mass content 60%;

[0067] Niacin 0.005g / L;

[0068] The balance of deionized water;

[0069] 2) The preparation method is the same as in Example 1;

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com