A multi-cathode sliding arc plasma igniter

A plasma and igniter technology, which is used in machines/engines, jet propulsion devices, gas turbine devices, etc., to achieve the effect of improving energy utilization, increasing contact area, and improving ignition ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

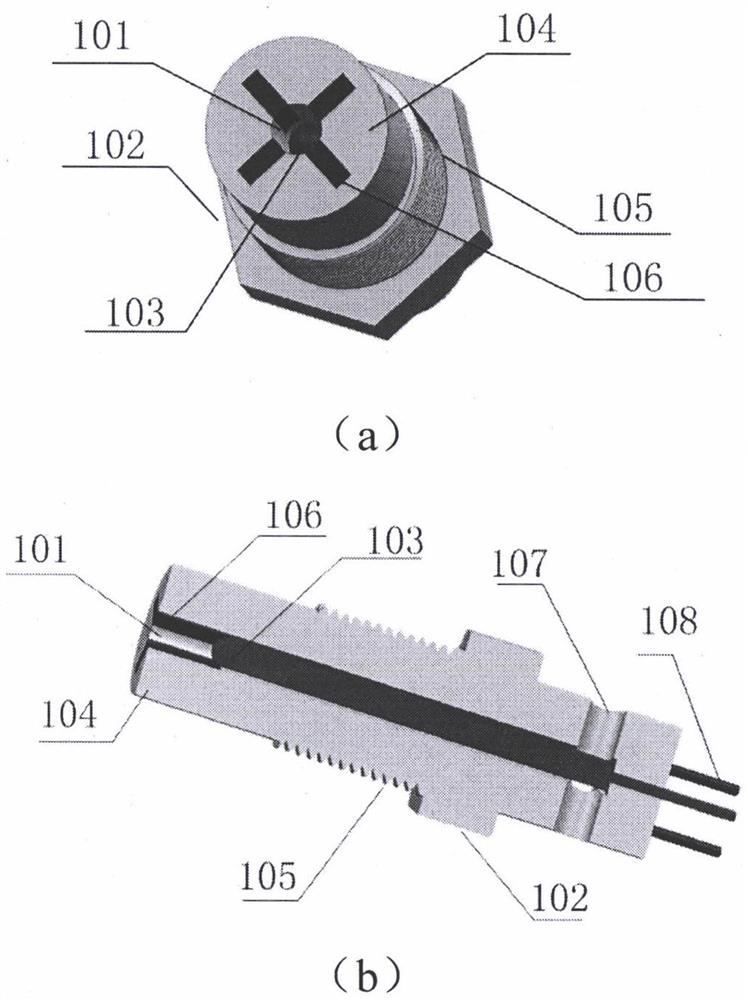

[0042] The main insulator 104 is made of glass-ceramics, and is a cylinder as a whole, with an outer diameter of 12-20mm, preferably 18mm, and a height of 80-200mm, preferably 100mm; the diameter of the jet hole 101 processed inside the main insulator 104 is 4-8mm. Preferably 5mm, the depth is 70-180mm, preferably 90mm; at the bottom of the insulator, four round holes are evenly processed in the circumferential direction as the air inlet 107, with a diameter of 3-8mm, preferably 5mm, and the air inlet communicates with the jet hole 101. The external high-pressure gas enters the igniter through the air inlet 107. On the one hand, it is used to drive the plasma channel to form a sliding arc, and on the other hand, it is used to cool the cathode 106 and the anode 103 to reduce electrode ablation. The cathode 106 is processed by four pieces of high-temperature-resistant metal, preferably metal tungsten, which is connected to the corresponding wire in the lead wire 108 through the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com