Modularized vibration absorber, vibration absorber module and machine tool

A vibration absorber and modular technology, applied in the field of vibration absorption, can solve the problems of unable to adjust the output force in real time and occupy a large space, and achieve the effect of compact structure, compact space, and increased air gap magnetic field strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

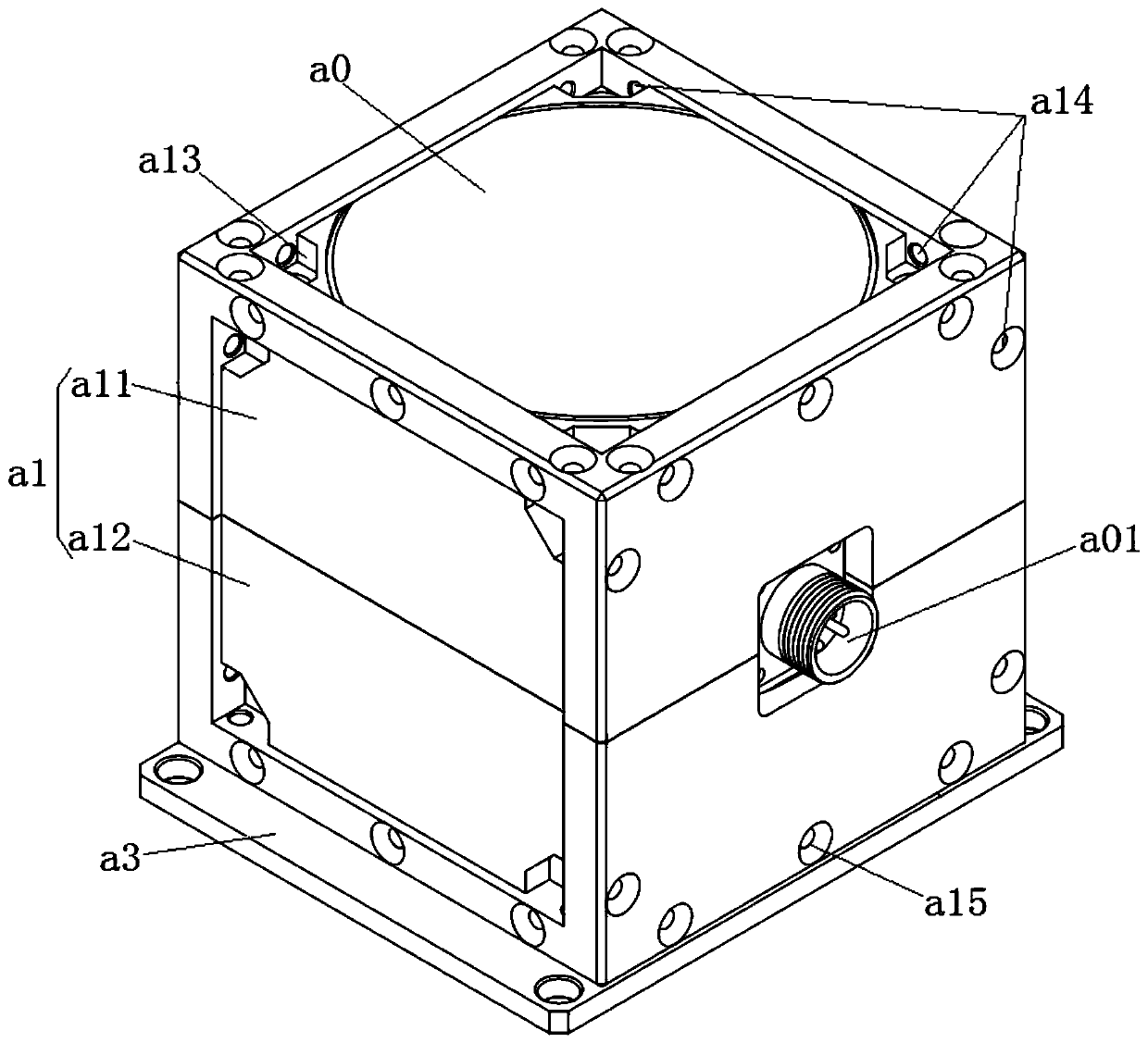

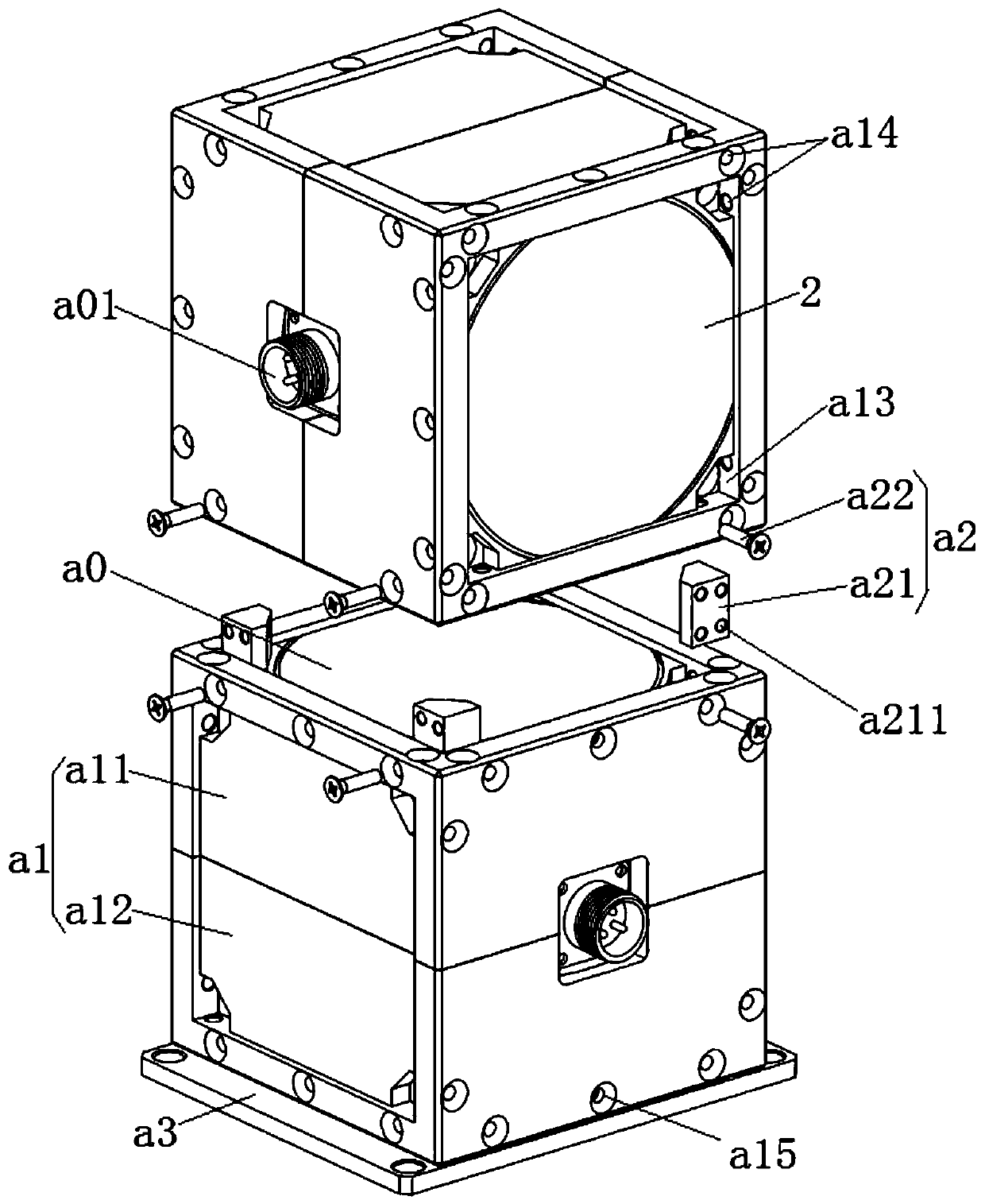

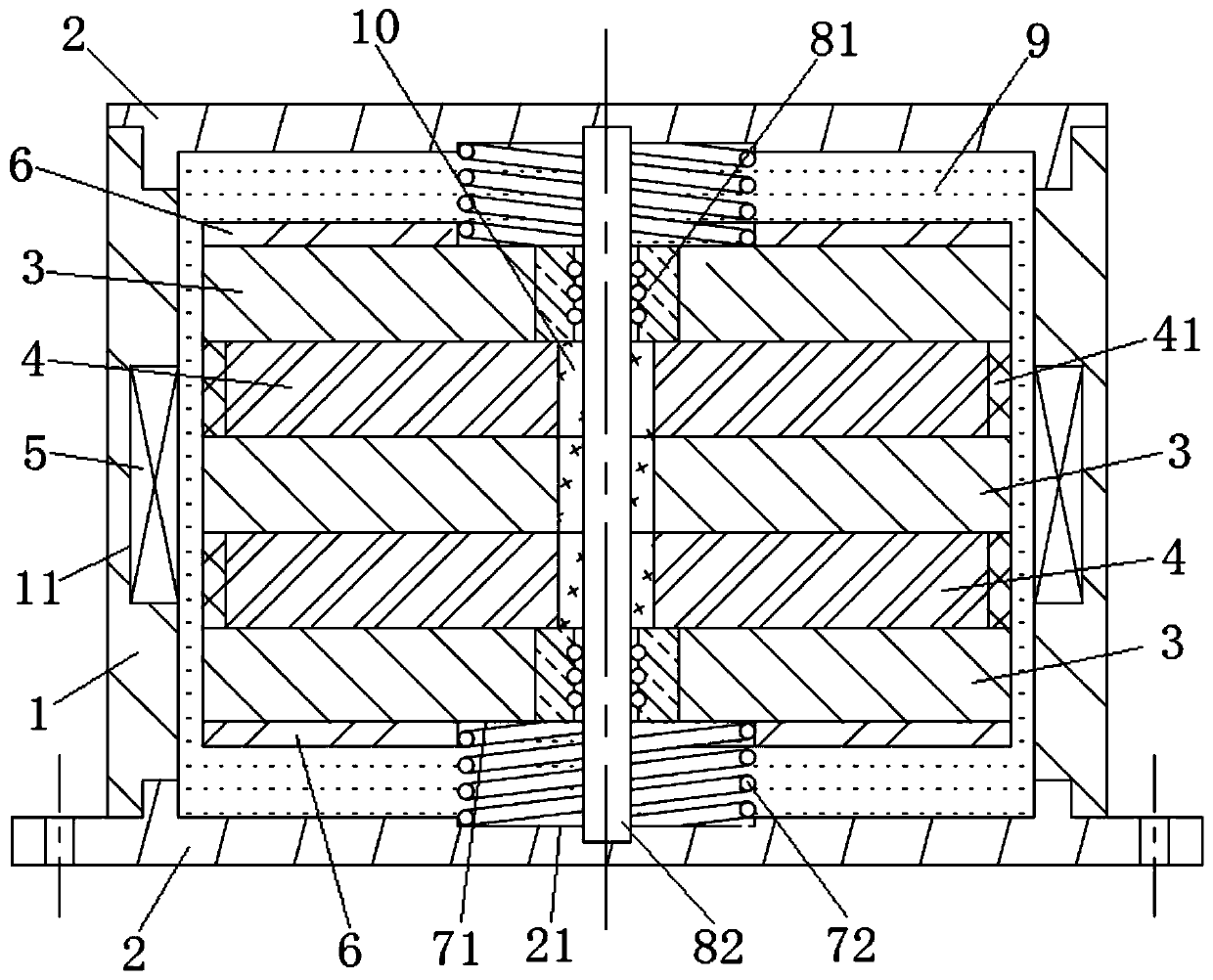

[0085] This embodiment provides a modular shock absorber, such as figure 1 As shown, it includes at least one vibration absorber unit and at least one set of connecting components a2 connecting the vibration absorber unit. The vibration absorber unit includes a vibration absorber unit a0 and a connection structure a1. The connection structure a1 is polyhedral, and it is sheathed outside the vibration absorber unit a0. Any inner wall surface of the connection structure a1 is at least partially in contact with the outer surface of the vibration absorber unit a0, so as to fully reduce the distance between the vibration absorber unit a0 and the connection structure a1. The space between the connection structure a1 and the vibration absorber unit a0 is more compact, and any surface on the polyhedron avoiding the plug a01 can be used as the connection surface, so that any two vibration absorber units a0 can pass through their respective The connection surfaces on the connection stru...

Embodiment 2

[0105] This embodiment provides a modular shock absorber. Compared with the technical solution of Embodiment 1, the difference is that, as Figure 4 As shown, the limit part of the vibration guide assembly of the vibration absorber unit a0 adopts a flange 73, and the flange 73 is coaxially threaded on the central axis 82 and fixed on the mover core 3 at both ends of the mover. 73 is located in the inner ring of the secondary permanent magnets 6 at both ends, and the elastic member adopts a leaf spring 74, which is symmetrically distributed about the flange 73. In the present embodiment, the leaf spring 74 is circular, and the edge of the circular inner ring is fixed on On the outer peripheral surface of the flange 73, the outer edge of the flange is fixed on the inner step of the seal between the cover plate 2 and the casing 1. When the mover is in a balanced state, the surface of the leaf spring 74 is arranged perpendicular to the axial direction of the mover.

[0106] As the...

Embodiment 3

[0109] This embodiment provides a vibration absorber module, including the external connector a3 and the modular vibration absorber in Embodiment 1 or Embodiment 2. Such as Figure 8 As shown, one of the connection structures a1 is provided with an external connector a3, and two modular shock absorbers are coaxially stacked and fixedly connected together with respect to the shock absorber unit a0 to form a shock absorber with twice the output force. Similarly, Three, four, etc. can be stacked coaxially to form a triple, quadruple output force absorber.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com