A load-sharing structure for flexible pins that eliminates the axial inclination of planetary gears

A planetary gear shaft and flexible pin technology, which is applied in the direction of belts/chains/gears, transmission parts, mechanical equipment, etc., can solve the problem of uneven tooth load distribution of planetary gears, eliminate the axial inclination of planetary gears, increase flexibility, Counteracts the effects of manufacturing and installation errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings.

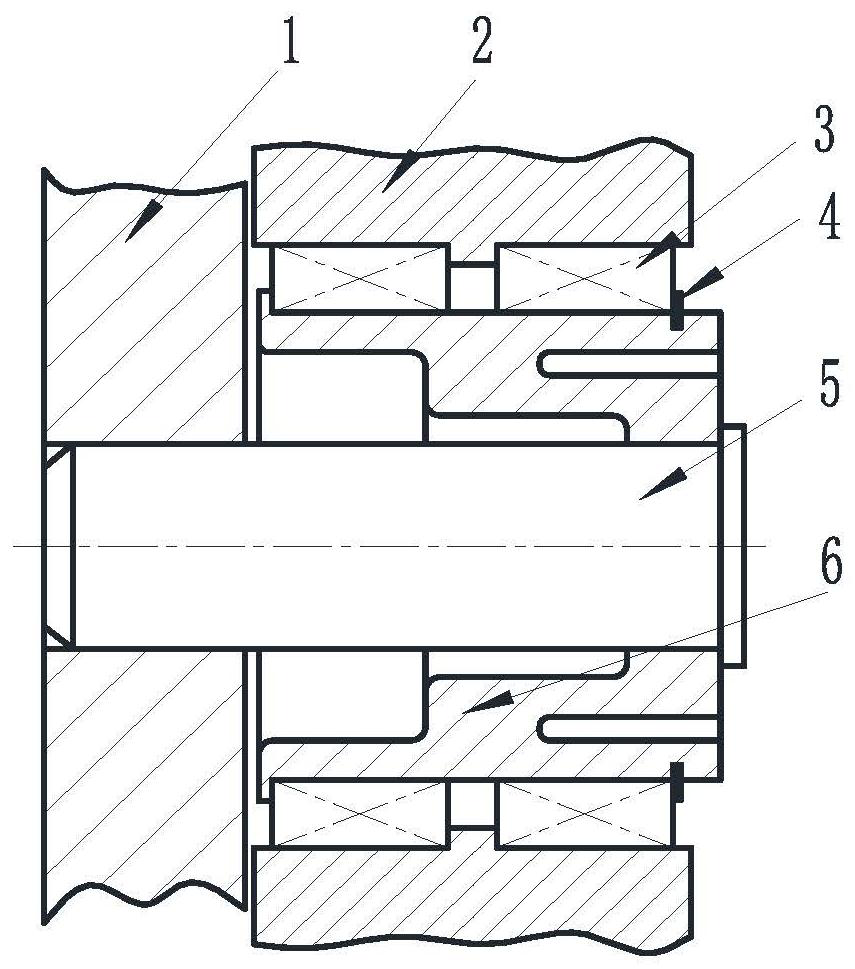

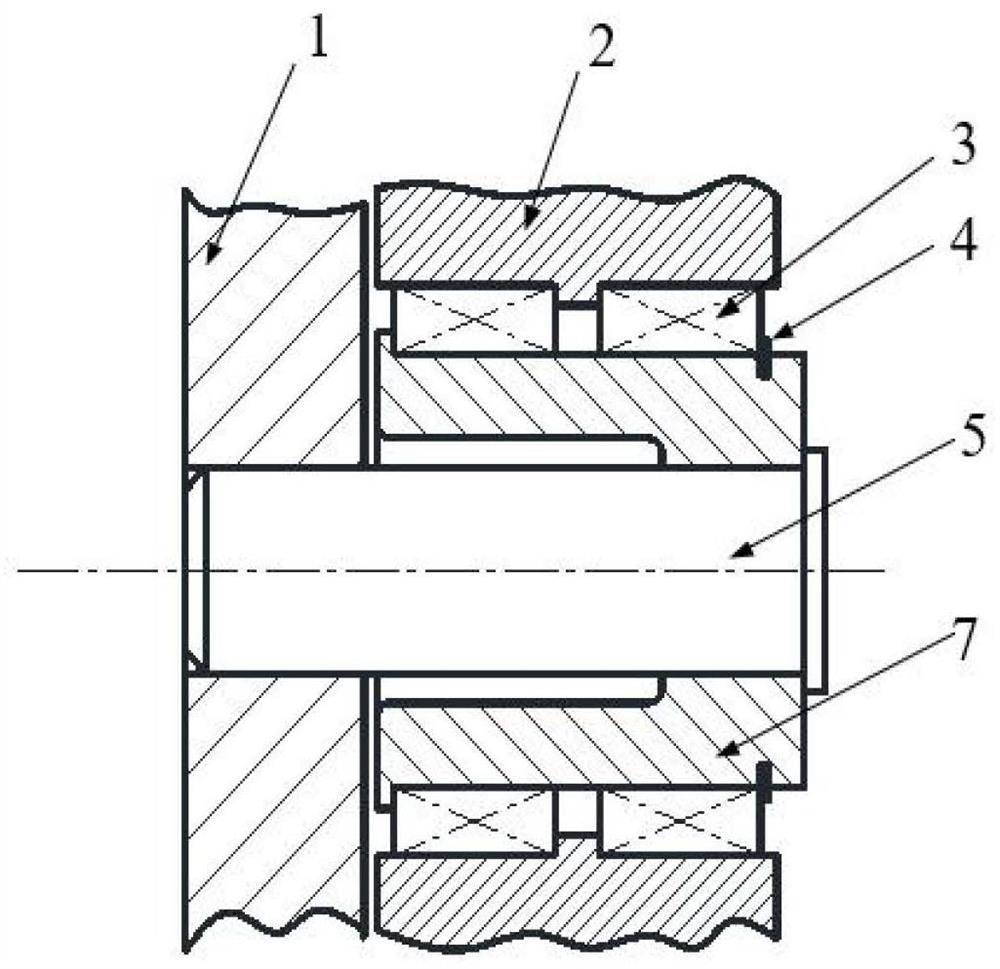

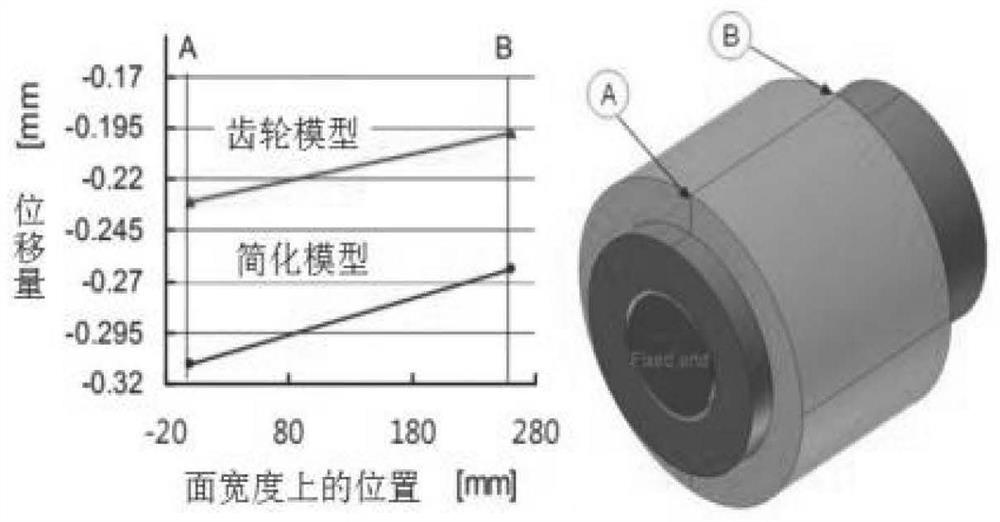

[0023] like figure 1 , Figure 5 Shown are a flexible pin shaft load sharing structure that eliminates the axial inclination of the planetary wheel, and a flexible pin shaft deformation principle diagram that eliminates the axial inclination of the planetary wheel. The present invention is a flexible pin shaft load-sharing structure for eliminating the axial inclination angle of the planetary wheel, which mainly consists of a planet carrier (1), a planetary wheel (2), a bearing (3), an elastic retaining ring (4), a pin shaft (5), The pin sleeve (6) is composed. Its installation process is as follows: first insert the small bore end of the pin bushing (6) from the shoulderless end of the pin shaft (5) until the shoulder of the pin shaft (5) and the small bore end of the pin bushing (6) Complete contact, the smallest diameter part of the pin sleeve (6) and the pin (5)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com