System and method for controlling humidity in alkali metal gas chamber

A technology of alkali metal gas chamber and control system, applied in humidity control, control/regulation system, non-electric variable control, etc., can solve problems such as low consistency and unstable anti-relaxation coating performance, and achieve improved consistency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

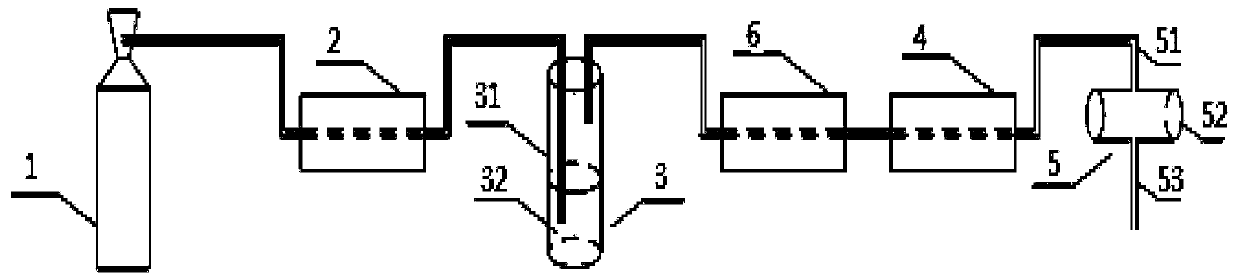

[0023] A humidity control system in an alkali metal gas chamber, comprising an inert gas pipeline through which an inert gas source device 1, a gas volume control device 2, a wetting device 3 and a humidity testing device 4 are sequentially connected, the The humidity testing device 4 inputs a set humidity inert gas into the alkali metal gas chamber 5, the inert gas source device 1 is a dry inert gas, and the gas volume control device 2 controls the dry inert gas to enter the wetting device 3, the humidity of the wet inert gas is tested by the humidity testing device 4 after the wetting device 3 wets the dry inert gas, and by adjusting the air intake and / or Or intake rate to obtain the set humidity inert gas.

[0024] When the measured humidity data of the humidity testing device 4 is lower than the humidity data of the set humidity inert gas, adjust the gas volume control device 2 to increase the intake air volume of the dry inert gas, when the humidity testing device 4 detec...

Embodiment 2

[0027] The difference between this embodiment and the above-mentioned embodiment is that the humidity control system in the alkali metal air chamber also includes a drying device 6 arranged between the wetting device 3 and the humidity testing device 4, and the drying device 6 is The humid inert gas whose humidity exceeds the set humidity inert gas is subjected to dry moisture absorption adjustment to obtain the set humidity inert gas.

[0028] When the measured humidity data of the humidity testing device 4 is higher than the humidity data of the set humidity inert gas, then by increasing the drying efficiency of the drying device 6, the humid inert gas flowing through the drying device 6 is adjusted to dry and absorb moisture Obtain the set humidity inert gas.

[0029] Preferably, the dry inert gas is nitrogen or argon. Preferably, the gas volume control device 2 can be a peristaltic pump or a flow meter. Preferably, the wetting device 3 can be a scrubber bottle 31 filled ...

Embodiment 3

[0031] Preferably, the humidity control system in the alkali metal air chamber further includes a humidity control module, the humidity control module includes a humidity data receiving sub-module and an air volume control sub-module, and the humidity data receiving sub-module is used to receive the humidity test Humidity data of the device 4, the gas volume control sub-module controls the gas volume control device 2 according to the humidity data, and then controls the intake air volume and / or intake rate of the dry inert gas entering the wetting device 3, to obtain The set humidity is inert gas.

[0032] Preferably, the humidity control module also includes a time control sub-module, and the time control sub-module starts timing from the time when the standard humidified inert gas enters the upper tailpipe 51 of the alkali metal gas chamber, and the main body 52 of the alkali metal gas chamber After the inside is at least completely wetted by the standard inert gas, the timi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com