AGV warehouse tray checking method based on RFID technology

A technology for pallets and warehouses, applied in the field of warehouse management systems, can solve problems such as inapplicability, inability to take inventory, and seriously affect the identification distance of RFID tags, so as to achieve the effect of reducing the area of operation channels and increasing the storage area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below in conjunction with embodiment and experimental example, the present invention will be further elaborated, and described embodiment and experimental example are only a part of embodiment of the present invention and experimental example, and these embodiments and experimental example are only for explaining the present invention, to the present invention The scope does not constitute any limitation.

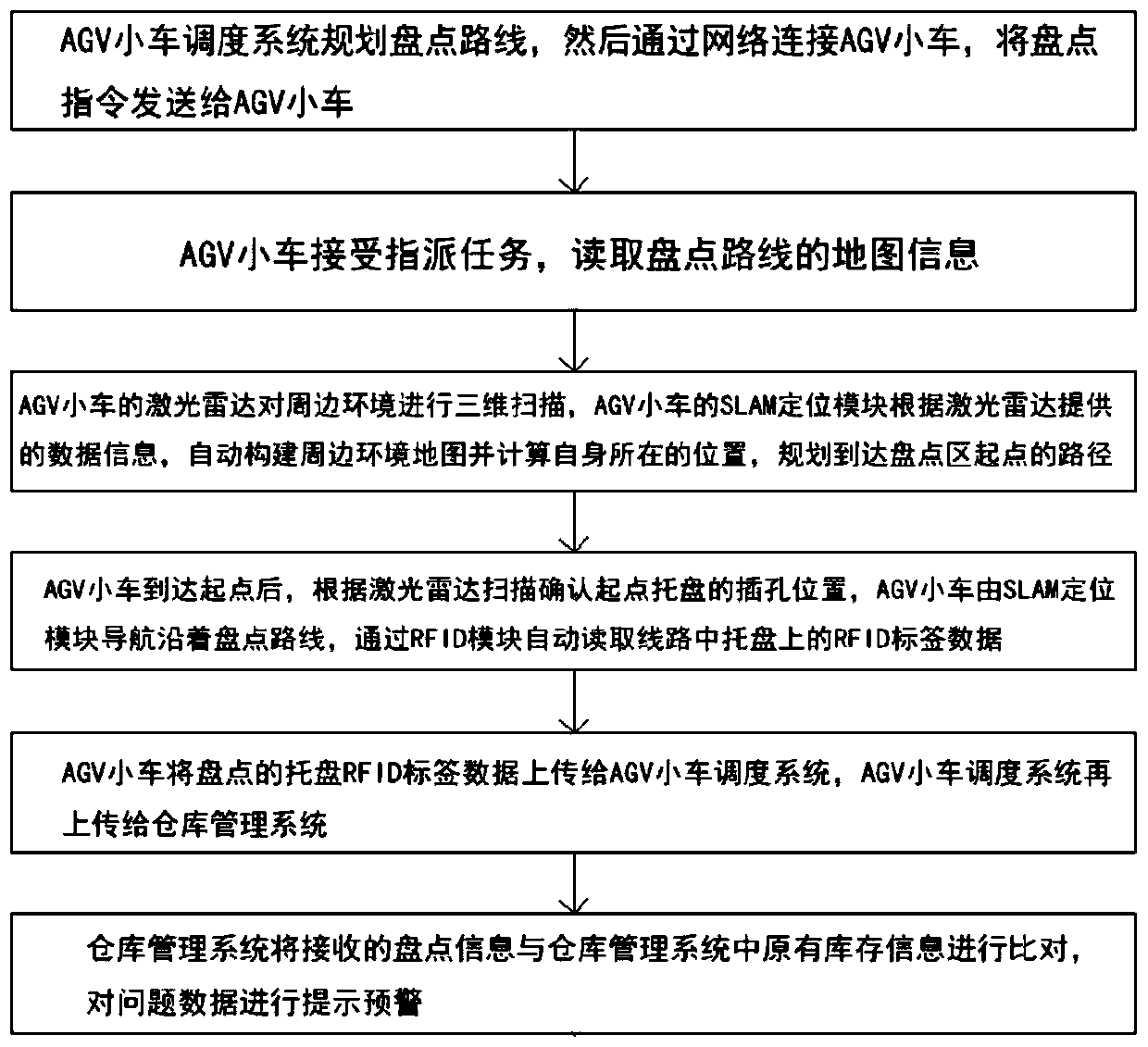

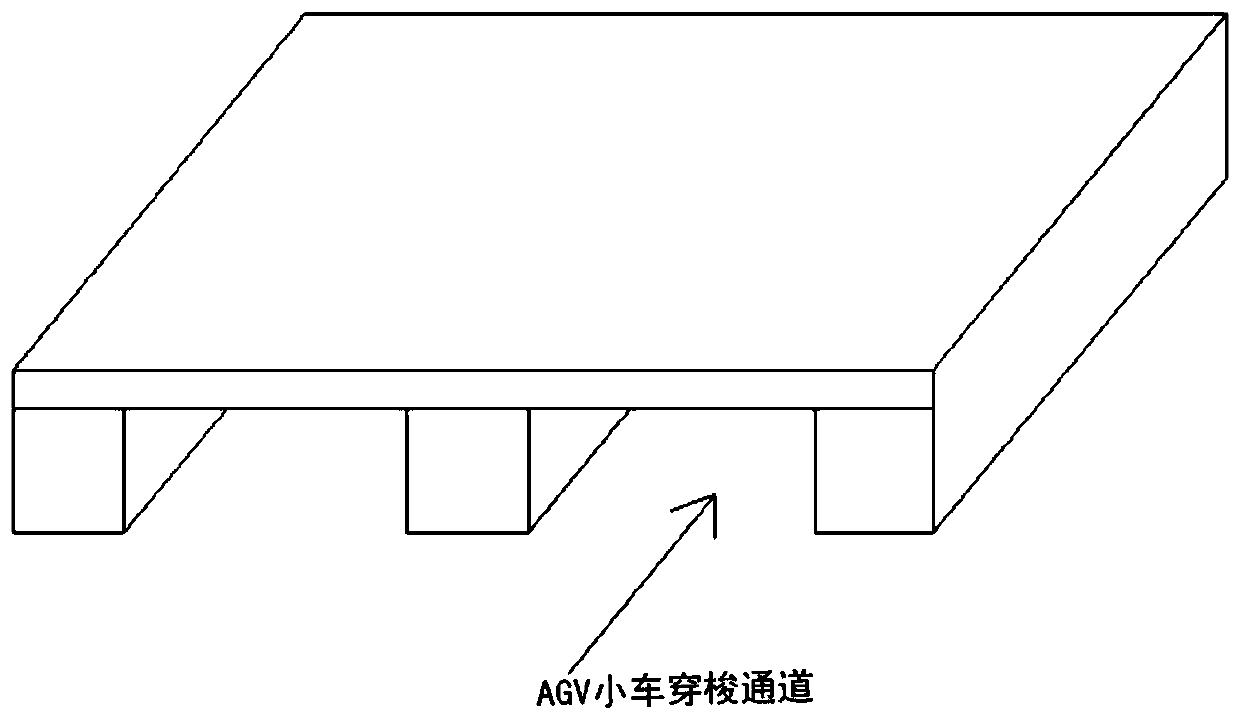

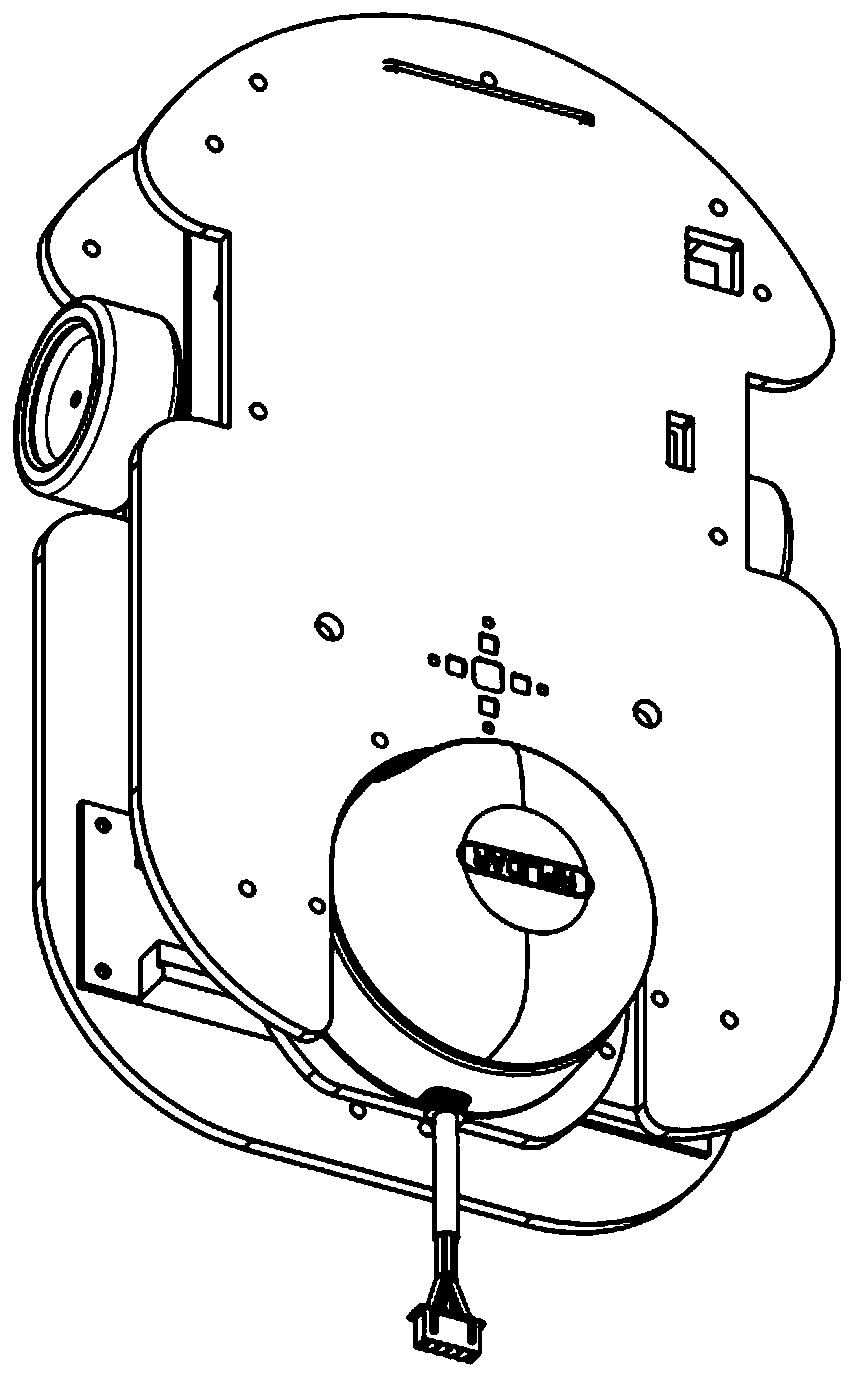

[0029] A method for AGV inventory warehouse pallets based on RFID technology, especially for single-storey storage scenarios in warehouses, ordinary guided transport vehicle AGVs cannot pass RFID modules in the middle of the pallet electronically in the peripheral warehouse passages When the tag (RFID tag) is read, a small AGV trolley is used to shuttle in the socket at the lower part of the pallet to read the electronic tag information of the pallet. Specifically include the following steps:

[0030] Step 1. The AGV car dispatching system plans the inventory route,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com