A vulcanization-free rubber insulated cable

An insulated cable, vulcanization-free technology, applied in the direction of insulated cables, insulated conductors, cables, etc., can solve the problems of high detection and maintenance costs, long detection and replacement time, shortened service life, etc., to achieve enhanced tear resistance and resistance Corrosion performance, reduced inspection and maintenance costs, and the effect of preventing mutual influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

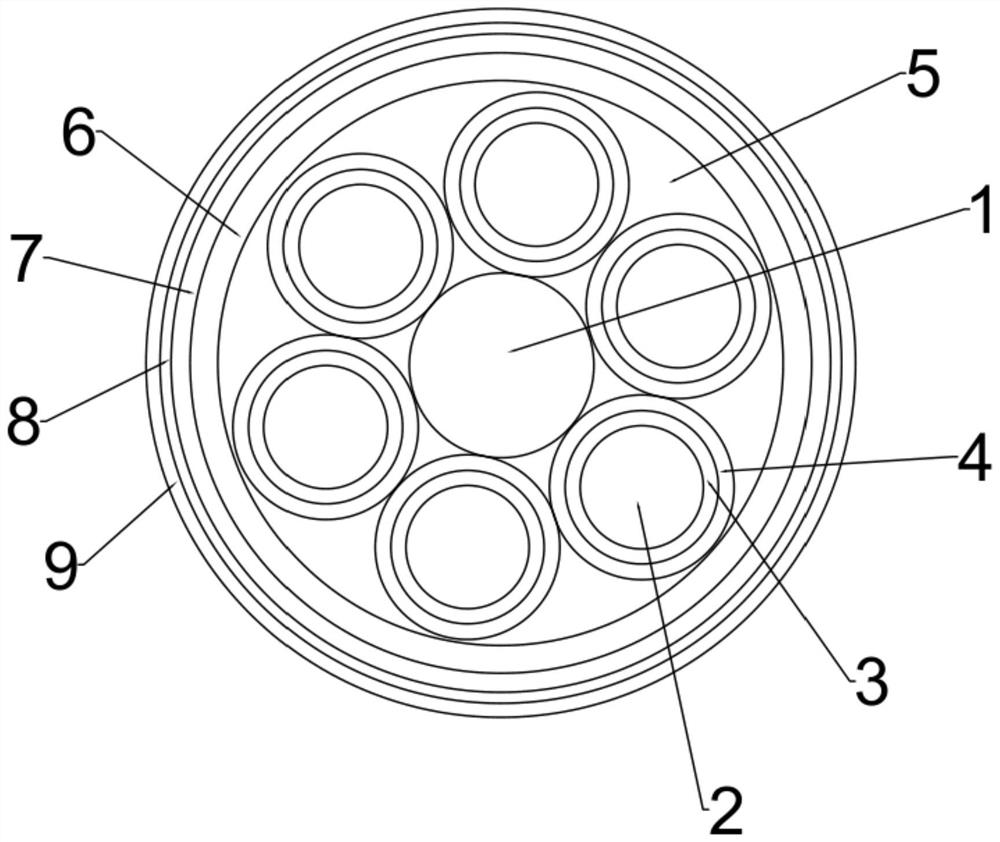

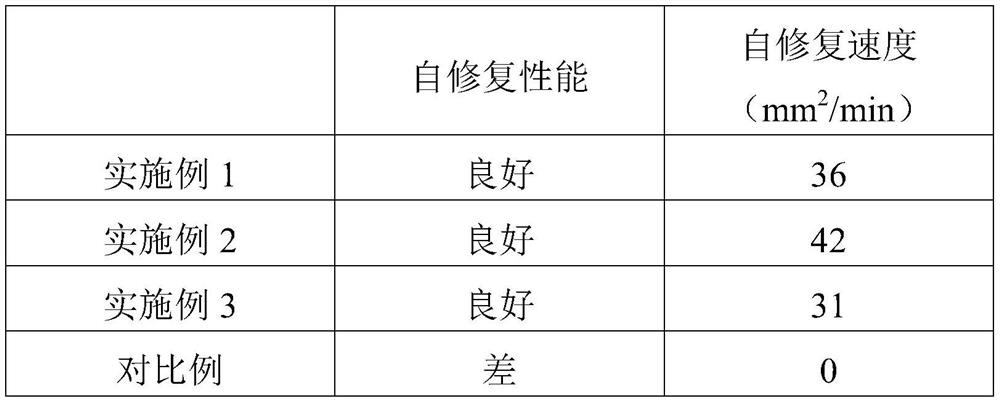

[0026] Embodiment 1: a vulcanization-free rubber insulated cable provided in this embodiment, which includes a support 1, a cable group arranged around the support 1, a protective layer covering the outer peripheral surface of the cable group, And the buffer layer 5 filled between the cable group and the protective layer, the cable group includes a number of twisted cables 2, the outer surface of the cable 2 is sequentially wrapped with an insulating layer from the inside to the outside 3 and a heat insulation layer 4, the protective layer includes a shielding layer 6, a vulcanization-free rubber layer 7 and a self-repairing layer 8 arranged sequentially from the inside to the outside;

[0027] The self-healing layer 8 is made of the following components in parts by mass: 10 parts of carbon nanotubes, 8 parts of graphene, 10 parts of urea, 16 parts of formaldehyde, 5 parts of polyurethane, and 4 parts of azobisisoheptanonitrile , 6 parts of dicyclopentadiene, 6 parts of OP-10,...

Embodiment 2

[0032] Embodiment 2: A vulcanization-free rubber insulated cable provided in this embodiment, which includes a support member 1, a cable group arranged around the support member 1, a protective layer covering the outer peripheral surface of the cable group, And the buffer layer 5 filled between the cable group and the protective layer, the cable group includes a number of twisted cables 2, the outer surface of the cable 2 is sequentially wrapped with an insulating layer from the inside to the outside 3 and a heat insulation layer 4, the protective layer includes a shielding layer 6, a vulcanization-free rubber layer 7 and a self-repairing layer 8 arranged sequentially from the inside to the outside;

[0033] The self-healing layer 8 is made of the following components in parts by mass: 8 parts of carbon nanotubes, 5 parts of graphene, 12 parts of urea, 18 parts of formaldehyde, 8 parts of polyurethane, and 6 parts of azobisisoheptanonitrile , 8 parts of dicyclopentadiene, 7 pa...

Embodiment 3

[0038] Embodiment 3: A vulcanization-free rubber insulated cable provided in this embodiment includes a support member 1, a cable group arranged around the support member 1, a protective layer covering the outer peripheral surface of the cable group, And the buffer layer 5 filled between the cable group and the protective layer, the cable group includes a number of twisted cables 2, the outer surface of the cable 2 is sequentially wrapped with an insulating layer from the inside to the outside 3 and a heat insulation layer 4, the protective layer includes a shielding layer 6, a vulcanization-free rubber layer 7 and a self-repairing layer 8 arranged sequentially from the inside to the outside;

[0039] The self-healing layer 8 is made of the following components in parts by mass: 10 parts of carbon nanotubes, 10 parts of graphene, 14 parts of urea, 20 parts of formaldehyde, 10 parts of polyurethane, and 7 parts of azobisisoheptanonitrile , 10 parts of dicyclopentadiene, 8 parts...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com