Variable step size disturbance observation energy-saving control method for three-phase asynchronous motor

A variable step size disturbance and energy-saving control technology, which is applied in motor control, motor generator control, AC motor control, etc., can solve the problems of motor operating efficiency decline and no change, so as to improve operating efficiency, ensure speed regulation performance, Avoiding the Effect of Search Oscillation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

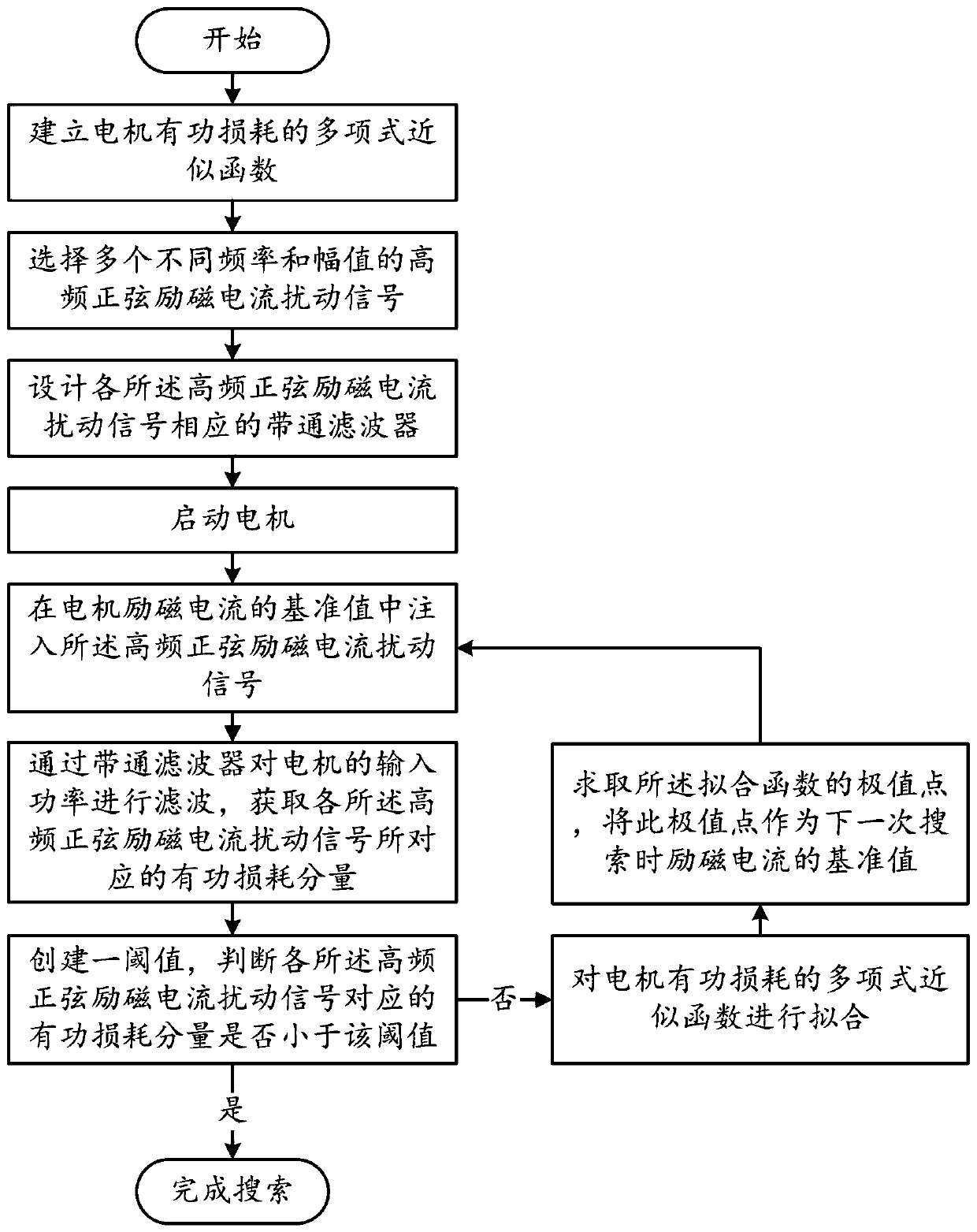

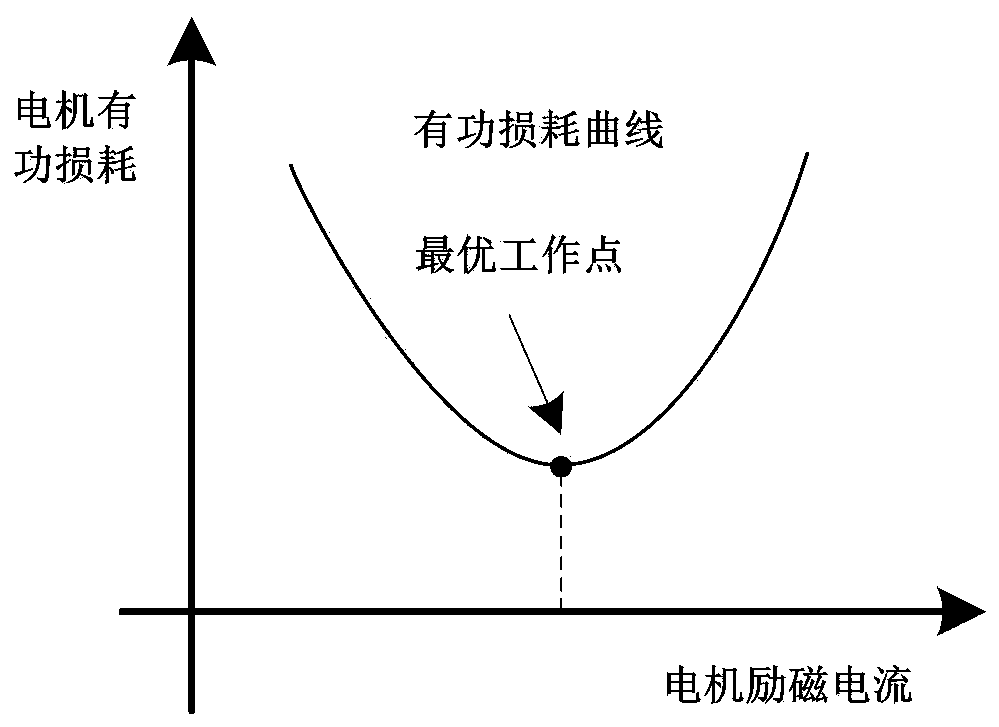

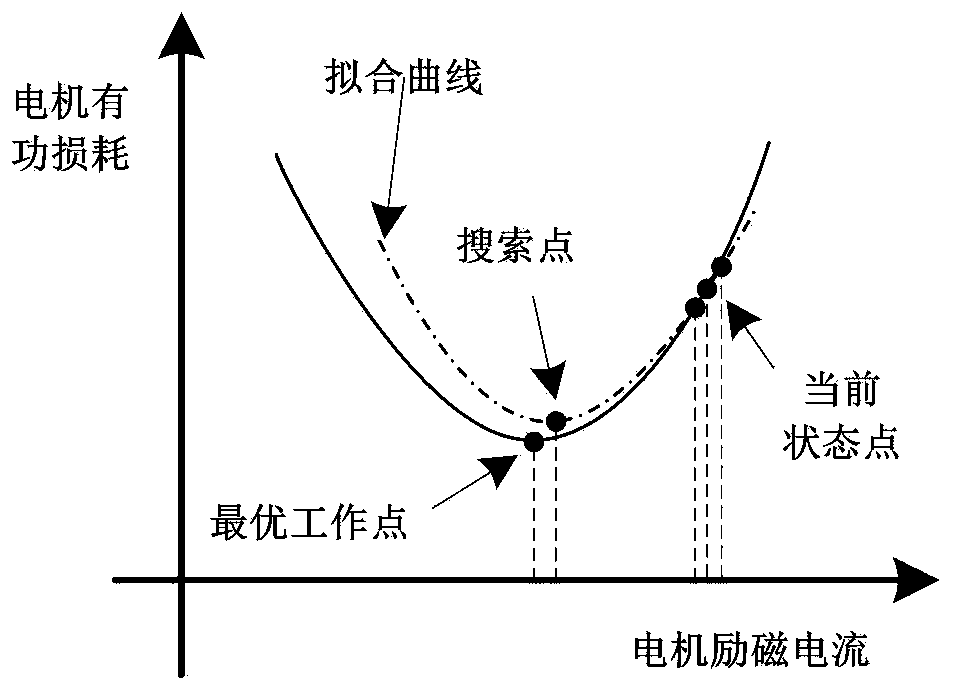

[0033] The general idea of the technical solution in the embodiment of this application is as follows: Since the high-frequency sinusoidal disturbance signal is injected into the excitation current of the motor, the electromagnetic torque, rotational speed and active power output of the motor can be approximately unchanged, so the change of the input power of the motor It is determined by the excitation current; it can be known from the motor loss model that the total active loss of the motor in the current state has a concave function relationship with the excitation current, that is, the total active loss of the motor decreases first and then increases with the increase of the excitation current, such as figure 2 As shown; the polynomial function is used to fit the concave function, and the minimum value point of the polynomial function is calculated as the reference value of the excitation current in the next search, and the excitation control of the motor is carried out t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com