Surface acoustic wave module one-step molded packaging structure and packaging process thereof

A surface acoustic wave and packaging structure technology, applied in electrical components, impedance networks, etc., can solve the problems of affecting performance, affecting shielding effect, single chip function, etc., and achieve the effect of reducing the package size, good shielding effect, and good overall performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

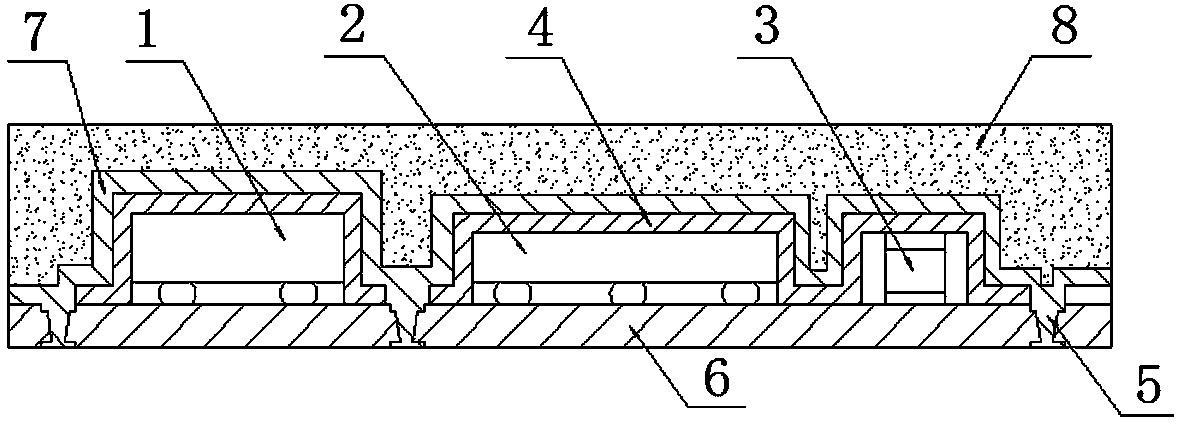

[0023] Embodiment 1: as attached figure 1 As shown, a packaging structure of a surface acoustic wave module is formed at one time, including a laminated board 6, and five acoustic surface bare chips 1, active devices 2 and passive devices 3 are arranged on the laminated board 6, and the active device 2 The device 2 includes a switch and an LNA. The passive device 3 includes three capacitors and four inductors. The laminated board 6 is provided with a via hole connection ground PAD5. An epoxy resin film 4 is provided on the mounting surface of the device 2 and the passive device 3, and a nickel layer 7 is provided on the epoxy resin film 4, and the nickel layer 7 is connected to the ground pad on the front side and the pad on the back side through a via hole. The ground PAD5 encapsulates the EMC layer 8 on the periphery of the nickel layer 7, and the EMC layer 8 is epoxy resin molding compound.

Embodiment 2

[0024] Embodiment 2: A packaging process for a packaging structure of a surface acoustic wave module, comprising the following steps,

[0025] In the first step, the SAW bare chip 1, the active device 2 and the passive device 3 are mounted on the laminate 6 through the SMT patch, gold ball flip chip or solder ball flip chip process; the active device 2 includes a A switch and an LNA, the passive device 3 includes three capacitors and four inductors;

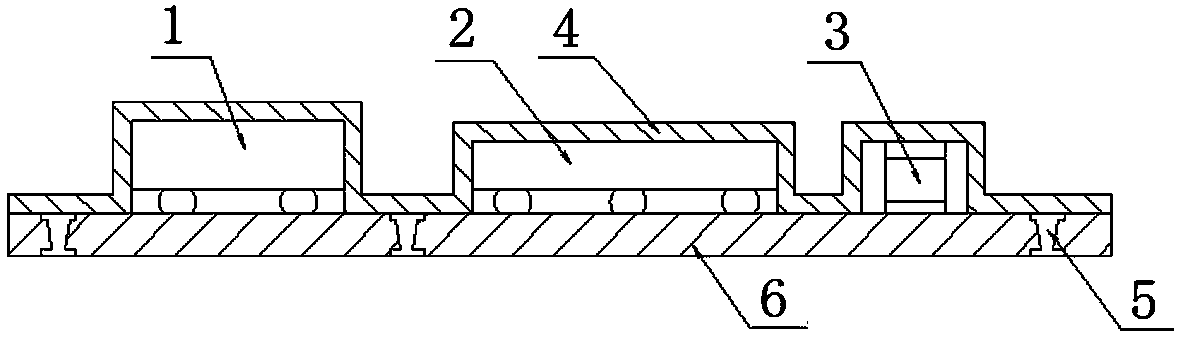

[0026] In the second step, cover the epoxy resin film 4 on the mounting surface of the acoustic surface bare chip 1, active device 2 and passive device 3, and after lamination by vacuum lamination equipment, solidify in an oven (such as figure 2 shown); the film has a good combination with the laminate and the device, and there is no resin filling at the bottom of the device, which can ensure the normal function of the surface acoustic wave device;

[0027] The third step is to pass the laminated plate of the cured epoxy resin ...

Embodiment 3

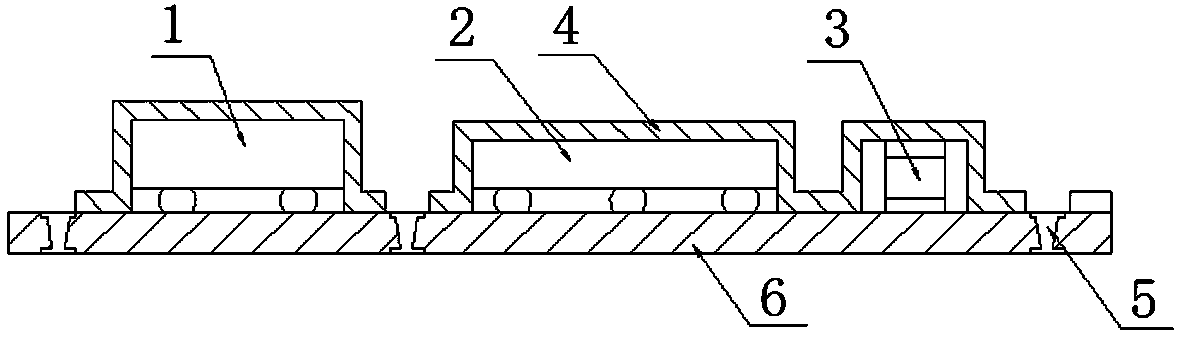

[0030] Embodiment 3: The packaging structure of the second surface acoustic wave module at one time, including a laminate 6, on which four SAW bare chips 1 and active devices 2 are arranged, and the active device 2 Includes a switch. The metal plating layer 7 is a copper layer. Others are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com