Rotary compressor

A technology of rotary compressors and compression chambers, which is applied in the direction of rotary piston machines, rotary piston pumps, rotary piston/swing piston pump components, etc., and can solve the problems that the piston cannot be installed on the eccentric part, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach 》

[0070] A first embodiment of the present invention will be described.

[0071] -The overall structure of the compressor-

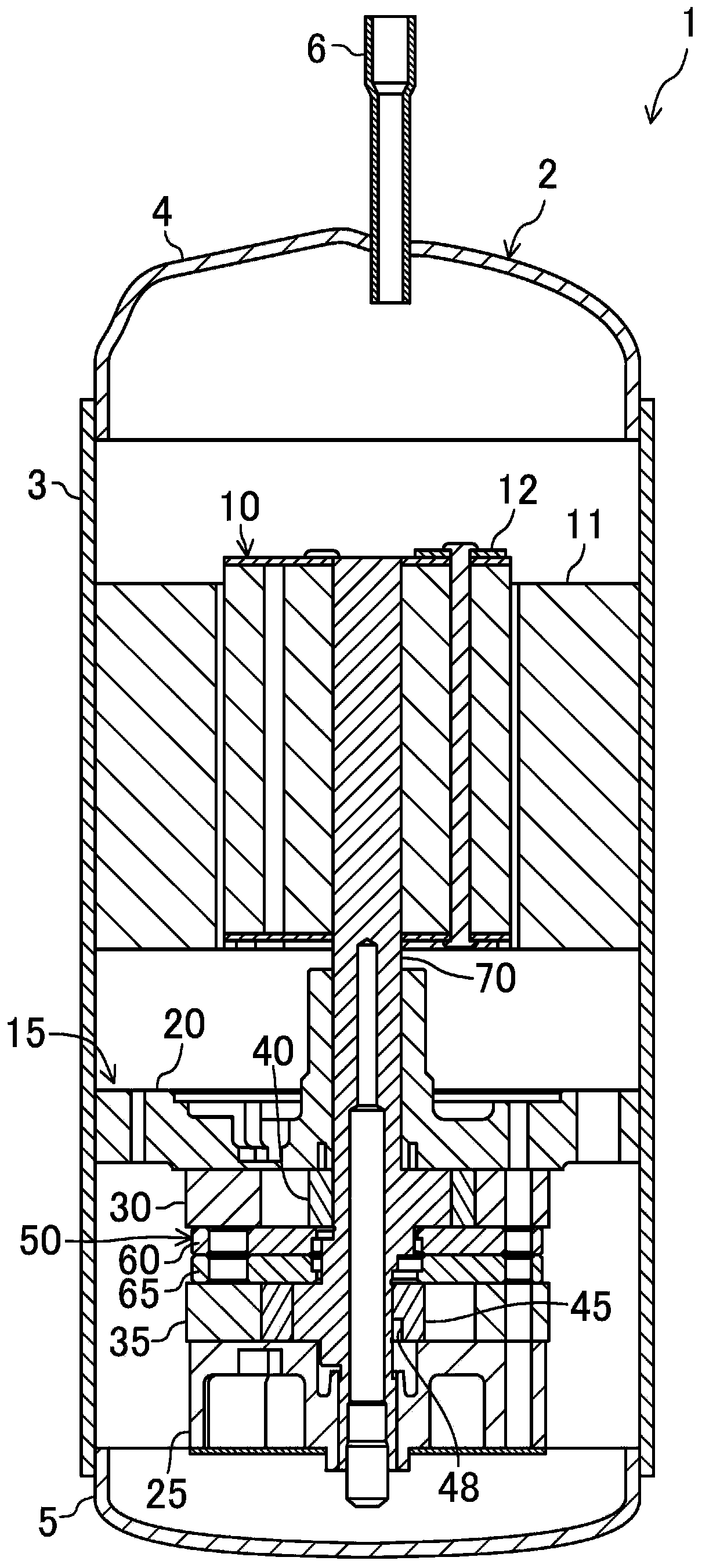

[0072] Such as figure 1 As shown, the compressor of this embodiment is a hermetic rotary compressor 1 . In the rotary compressor 1 , a compression mechanism 15 and a motor 10 are housed in a casing 2 . The rotary compressor 1 is installed in a refrigerant circuit that performs a vapor compression refrigeration cycle, and compresses refrigerant that has been evaporated by an evaporator by sucking it in.

[0073] The casing 2 is a cylindrical airtight container in an upright state. The casing 2 includes a cylindrical body portion 3 and a pair of end plates 4 and 5 that block the ends of the body portion 3 . A suction pipe (not shown) is attached to the lower portion of the trunk portion 3 . A discharge pipe 6 is attached to the upper end plate 4 .

[0074] The electric motor 10 is arranged in an upper portion of the inner space of the housing 2 . The ...

no. 1 approach

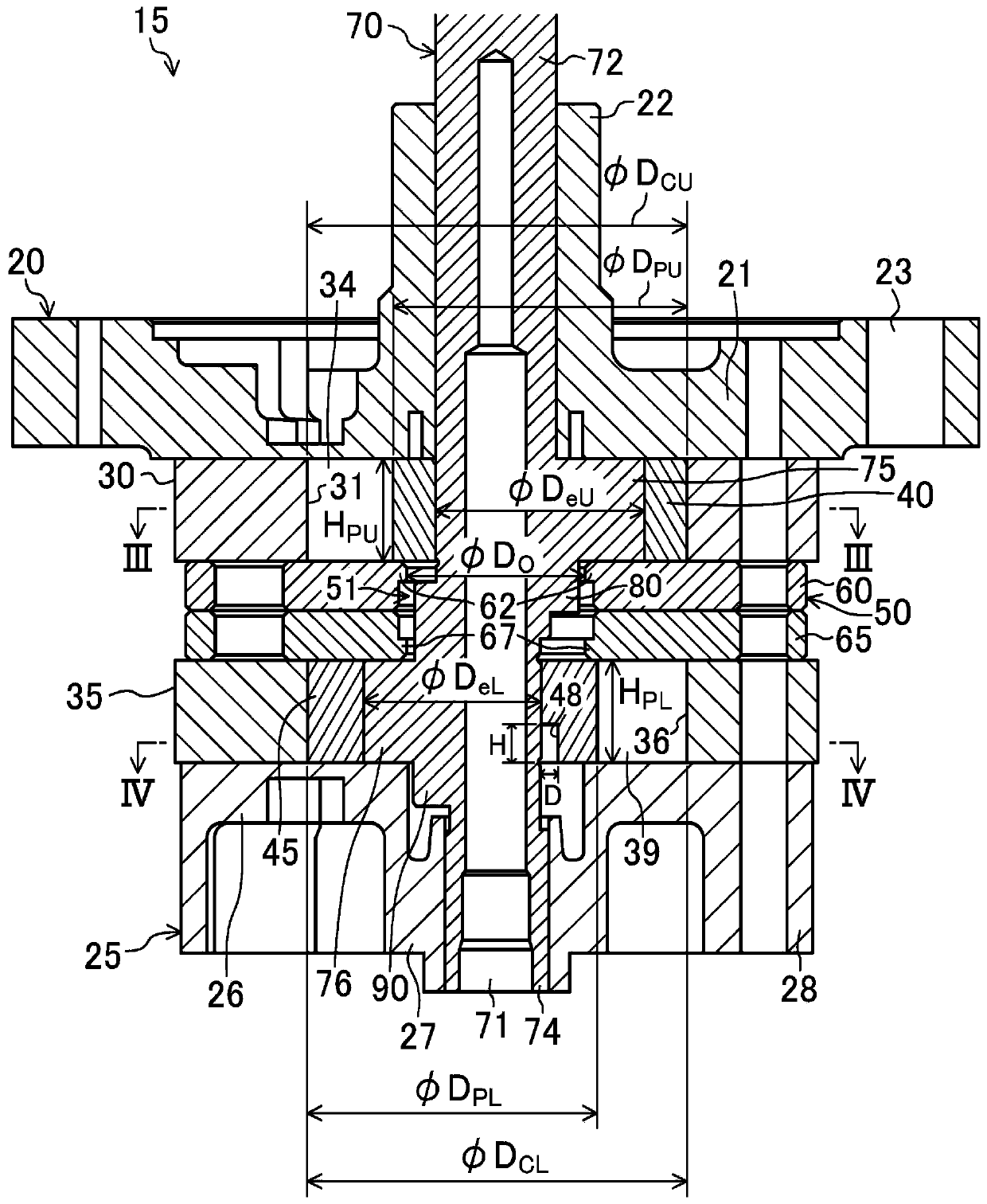

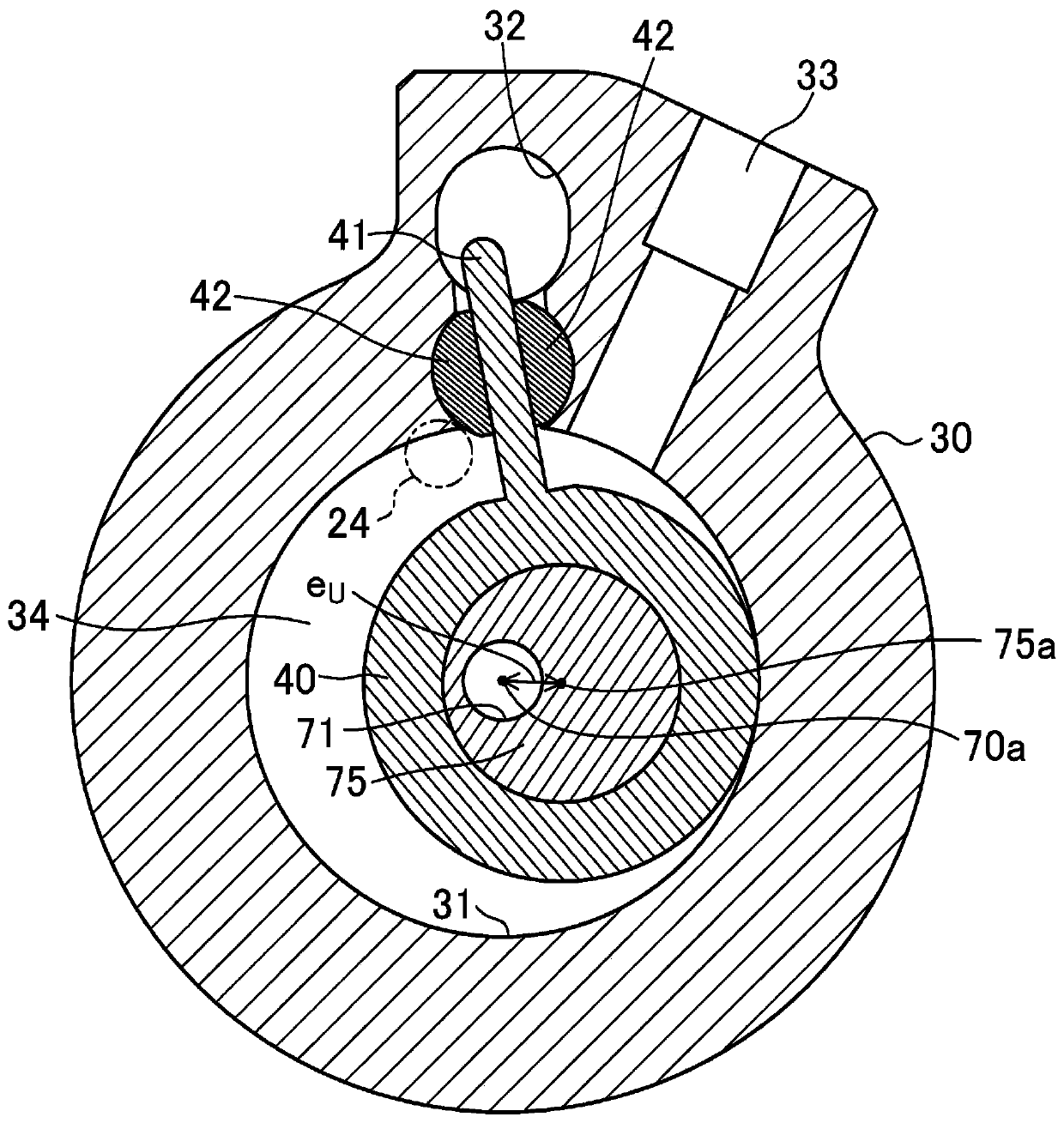

[0196] In addition, in the first embodiment, the drive shaft 70 is configured such that the distance r which is the minimum value of the distance from the rotation center axis 70 a of the drive shaft 70 to the outer peripheral surface of the upper eccentric portion 75 8 The radius R of the spindle portion 72 M Above (r 8 = R eU -e U ≥R M ). That is, the drive shaft 70 is configured such that the outer surface of the drive shaft 70 is not dented toward the eccentric side at the upper eccentric portion 75 . Therefore, when assembling the lower piston 45 and the upper piston 40 to the lower eccentric portion 76 and the upper eccentric portion 75, the drive shaft 70 can be inserted into the lower piston 45 from the counter shaft portion 74 side and can be inserted from the main shaft portion 72 side. The upper piston 40 is inserted and assembled. Accordingly, instead of assembling the upper piston 40 to the upper eccentric portion 75 over the lower eccentric portion 76 , the...

other Embodiment approach

[0198] The above-described embodiments may also take the following configurations.

[0199] In the first embodiment described above, the first coupling portion is formed between the counter shaft portion 74 and the lower eccentric portion 76 so that the drive shaft 70 satisfies R eL -e L S , but it may also be configured such that the first connecting portion according to the present invention is formed between the main shaft portion 72 and the upper eccentric portion 75 so that the drive shaft 70 satisfies R eU -e U M .

[0200] Specifically, in the first embodiment described above, the lower cylinder 35 constitutes the first cylinder, the lower piston 45 constitutes the first piston, the lower eccentric portion 76 constitutes the first eccentric portion, and the subshaft portion 74 constitutes the first piston. The upper cylinder 30 constitutes the second cylinder, the upper piston 40 constitutes the second piston, the upper eccentric portion 75 constitutes the second ecc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com