Fish slice processing and intelligent sorting integrated device and method

A fish body and slicing technology, which is applied in the processing of fish, fish sorting, cephalopod processing, etc., can solve the problems of low efficiency of manual slicing, sorting of unqualified products, low yield, etc., to solve the cutting efficiency. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

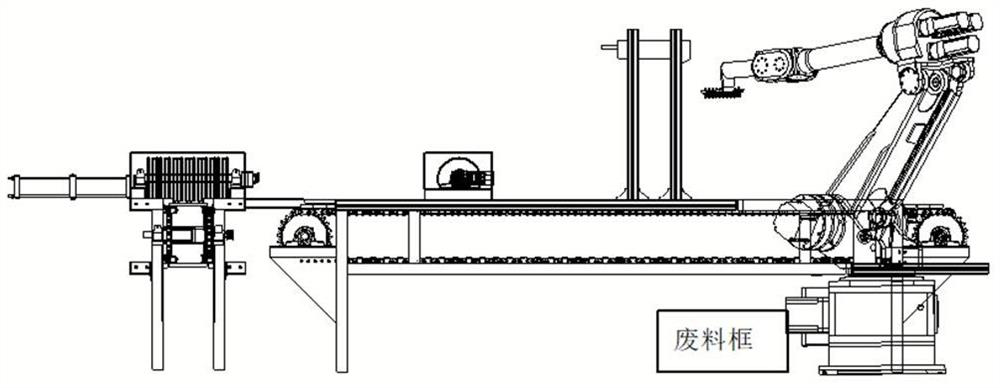

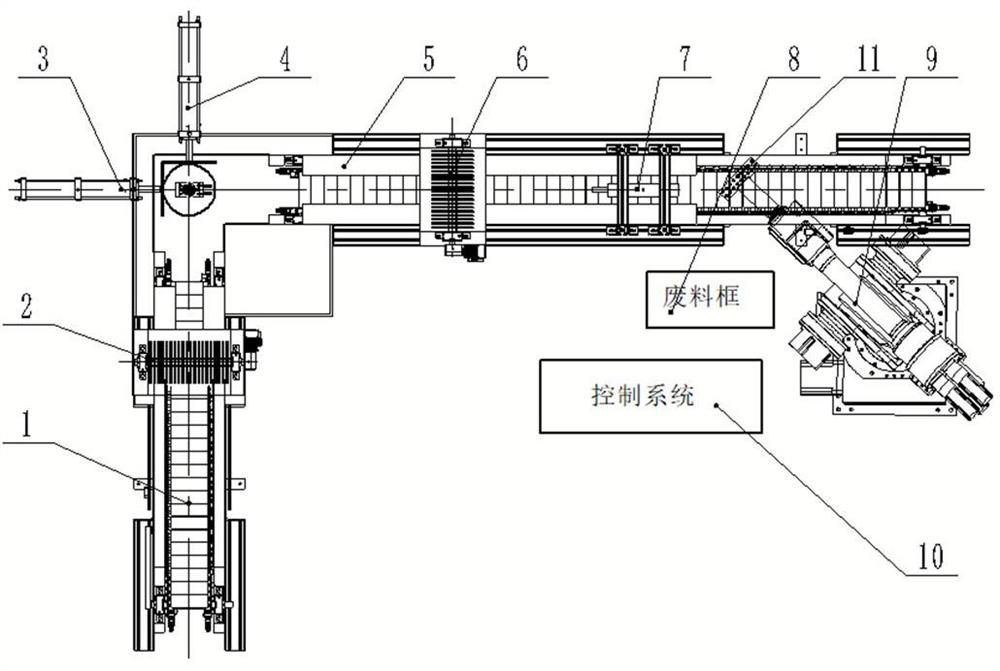

[0026] The present invention will be further described below in conjunction with the accompanying drawings.

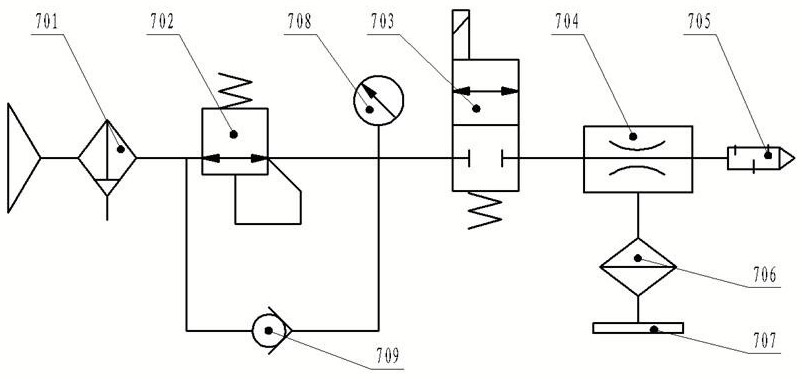

[0027] The invention mainly includes a fish body sprocket conveying mechanism, a cutting knife row, a propulsion mechanism, a one-side leveling mechanism, a 3D scanning system, and a fish body leftover material selection and sorting mechanism.

[0028] The fish body longitudinal sprocket conveying mechanism and the fish body transverse sprocket conveying mechanism have the same structure, and both include a conveying chain plate, a metal liner, a built-in drive motor, a conveyor belt driving sprocket, a conveyor belt driven sprocket and a sprocket tightening mechanism. The inner two ends of the conveyor chain plate are respectively fixed by the conveyor belt driving sprocket and the conveyor belt driven sprocket. A metal liner is lined on the inner side of the lower surface of the conveyor chain plate. The sprocket tensioning mechanism tightens the chain, and the built...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com