Method for preparing tar extract with aroma characteristic by using waste cigarette butts and application of tar extract in cigarettes

An extract and tar technology, which is applied in the field of tobacco technology, can solve problems such as not involving the extraction process of cigarette butts, and achieve the effects of broadening the scope of application and usage, wide source of raw materials and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Example 1 Extraction of tar extract with aroma-inducing properties from waste cigarette butts

[0033] A method of utilizing waste cigarette butts to prepare a tar extract with aroma-causing properties, comprising the following steps:

[0034] (1) pretreatment of discarded cigarette butts: tear off the tipping paper of discarded cigarette butts, remove residual tobacco shreds and cigarette paper, collect fiber tow, and cut the tow into small sections less than 1 cm long;

[0035] (2) put 20g of processed waste cigarette butts in the subcritical extraction tank, inject 800mL of n-butane, carry out subcritical extraction, extraction pressure 1.0MPa, extraction temperature 40 ℃, extraction time is 70min, extract once, obtain extraction liquid;

[0036] (3) after the extract is vacuum filtered, the filtrate is distilled under reduced pressure at 30°C under 0.07Mpa conditions to obtain concentrated extract;

[0037] (4) the concentrated extract is carried out two-stage mo...

Embodiment 2

[0056] Example 2 Applying tar extract to cigarettes

[0057] The cigarette tar extract prepared in Example 1 was added to the cigarette filter tip at a proportion of 2% by weight of the cigarette, to prepare a cigarette sample A with tar aroma components added.

[0058] The cigarette tar extract prepared in Example 1 was added to the shredded cigarette in a proportion of 2% of the weight of the cigarette, to prepare a cigarette sample B with tar aroma components added.

[0059] The cigarette tar extract prepared in Example 1 was added to the shredded cigarette in a proportion of 3% of the weight of the cigarette, to prepare a cigarette sample C with tar aroma components added.

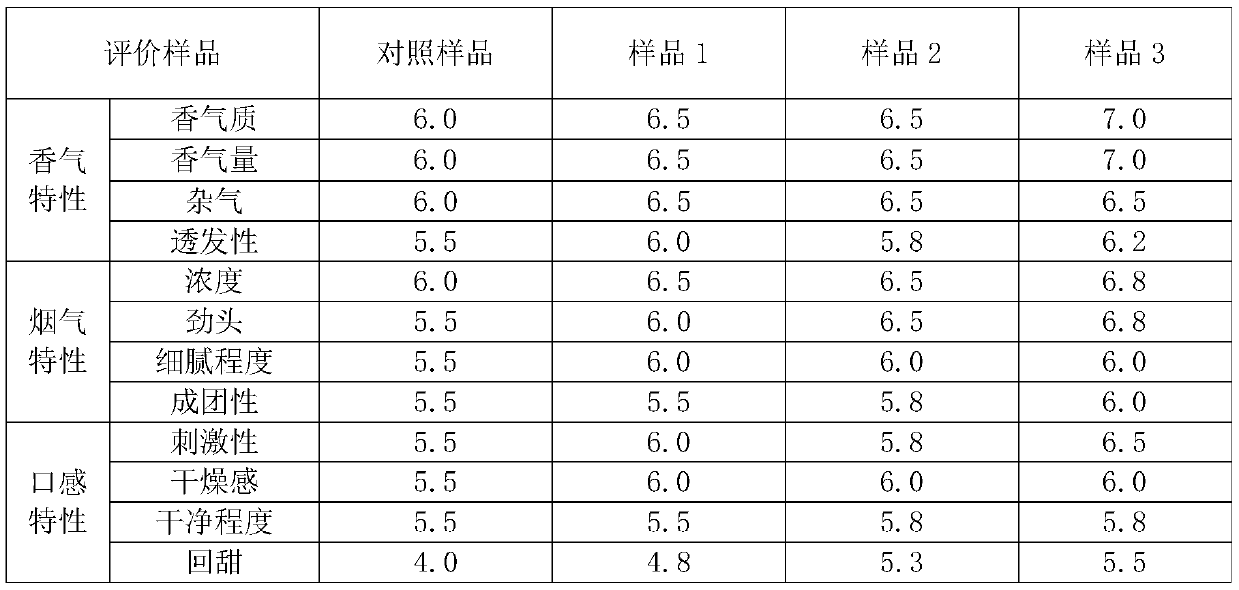

[0060] After equilibrating the cigarette samples prepared by the above scheme and the cigarettes without adding tar aroma components in a constant temperature and humidity environment of (20 ± 1) ℃ and relative humidity of (60 ± 3)% for 24 hours, 10 or more people were organized to evaluate the smoki...

Embodiment 3

[0064] Example 3 Selection of preparation method conditions

[0065] 1. Selection of extraction pressure

[0066] Weigh 20g of the treated waste cigarette butts, add them into a subcritical extraction tank, and then inject 800 mL of n-butane into the extraction tank. The waste cigarette butts were extracted subcritically under MPa, and the extraction was performed once for 70 minutes. The effects of different extraction pressures on the extraction effect were compared and analyzed. The test results are shown in Table 2. It can be seen from Table 2 that the extraction effect at 1.0 MPa is the best.

[0067] Table 2 Extraction effect of different extraction pressures (mg / g)

[0068]

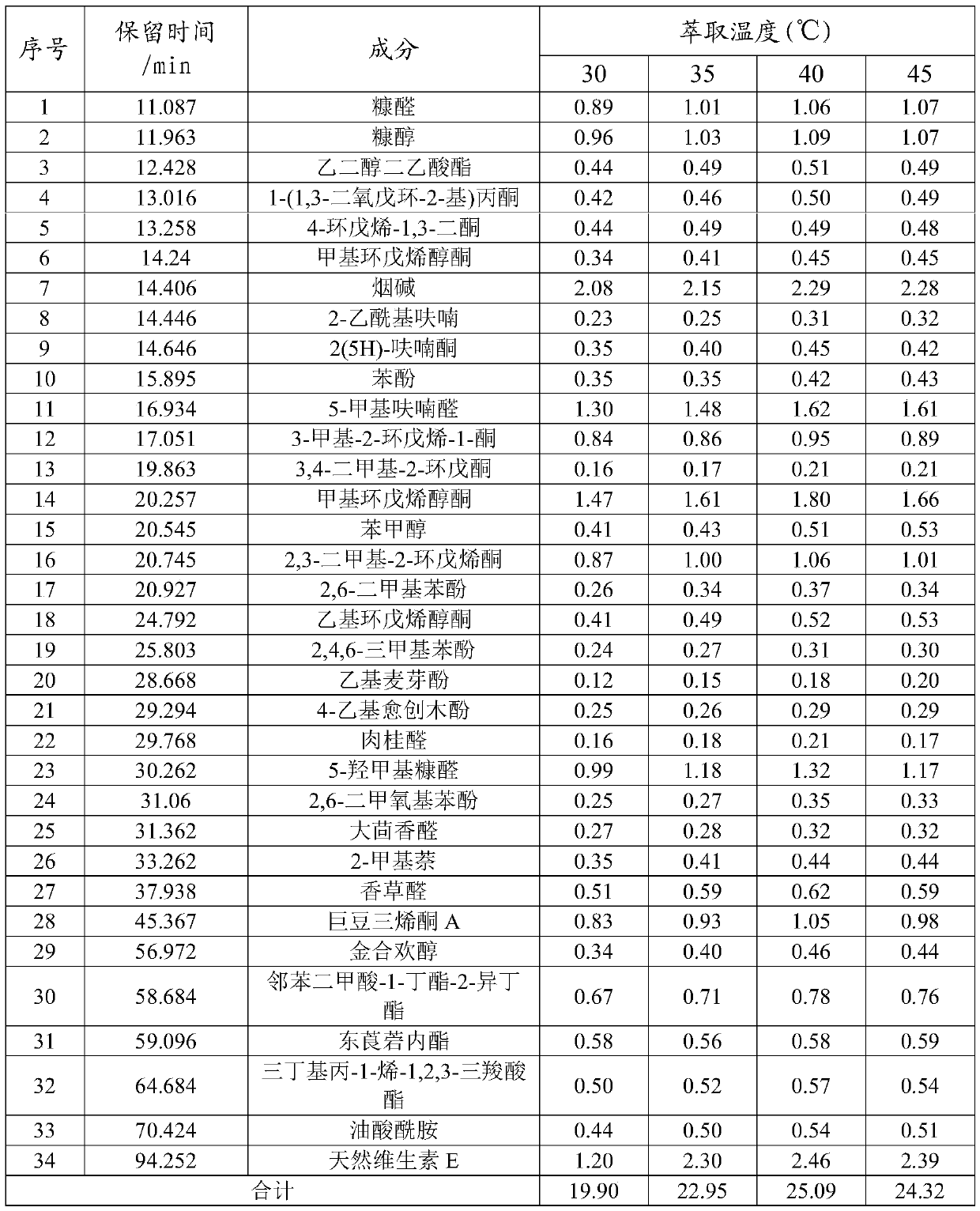

[0069] 2. Selection of subcritical extraction temperature

[0070] Weigh 20 g of the treated waste cigarette butts, add them into a subcritical extraction tank, and then inject 800 mL of n-butane into the extraction tank. The extraction pressure is set to 1.0 MPa, and the extraction tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com