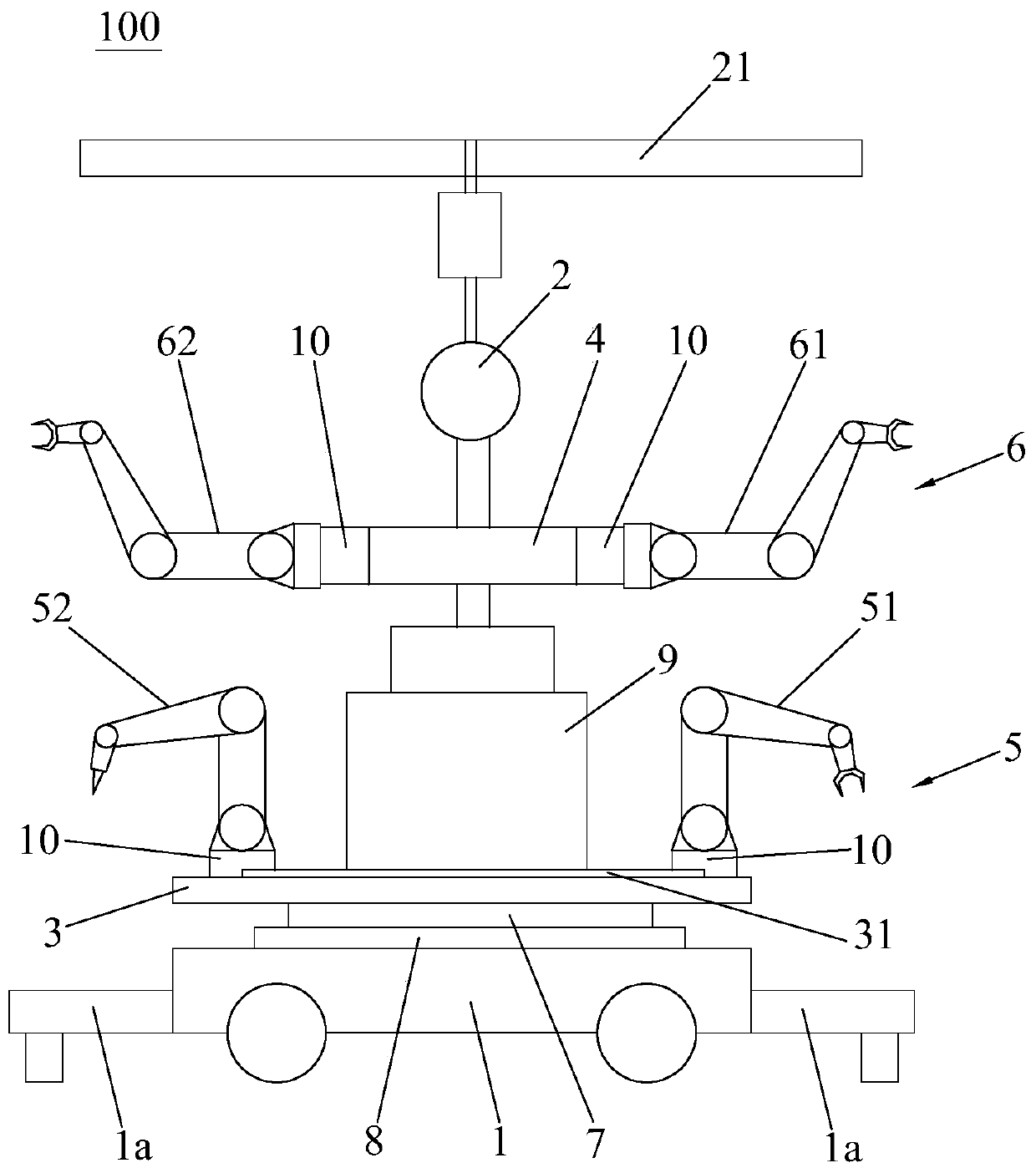

Building reinforcing steel bar construction robot

A technology of building steel bars and robots, which is applied in the field of robots, can solve problems such as low construction efficiency, high labor intensity of workers, troublesome positioning and binding or welding and fixing, and achieve the effects of reducing labor intensity, improving construction efficiency, and realizing automated production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

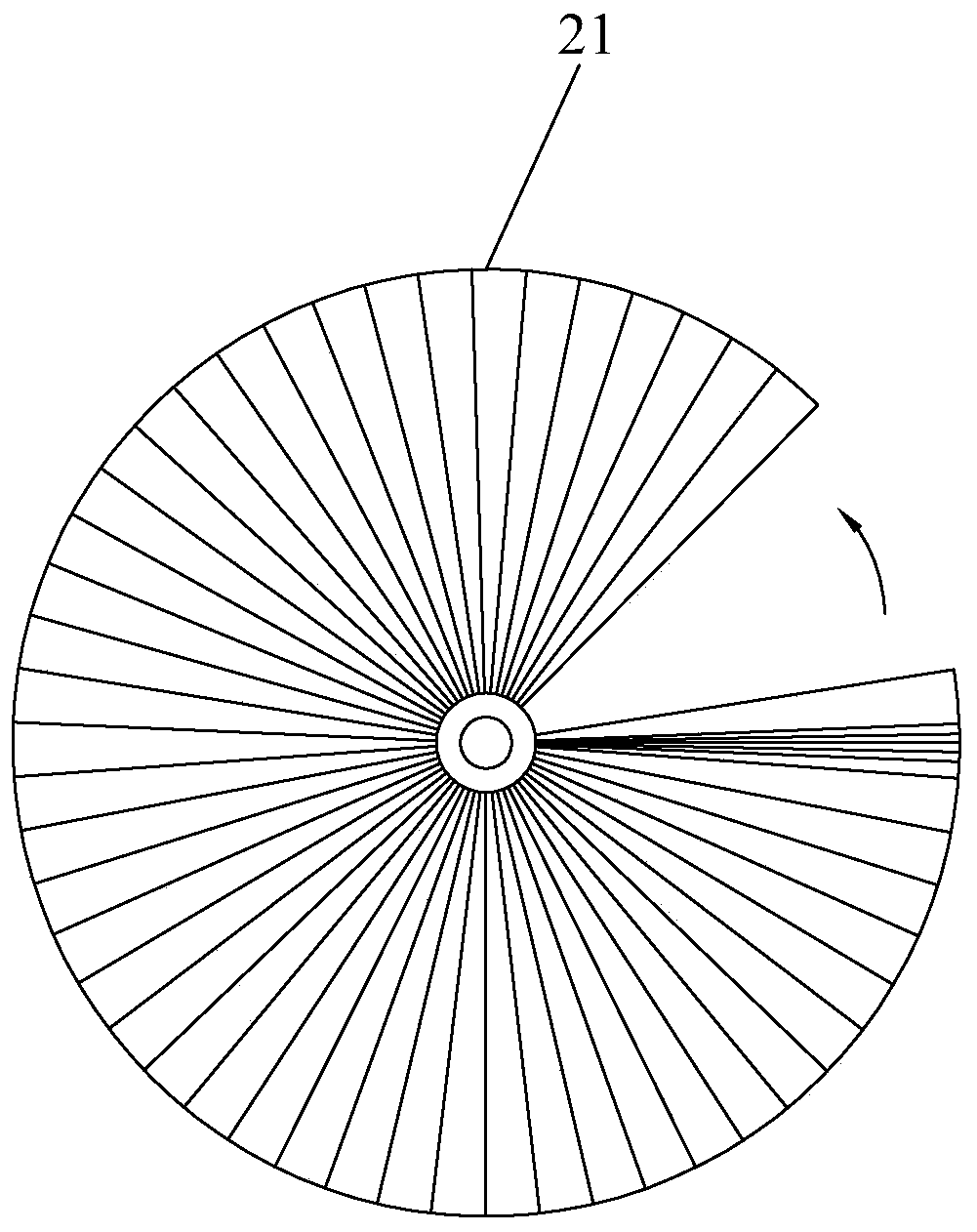

Method used

Image

Examples

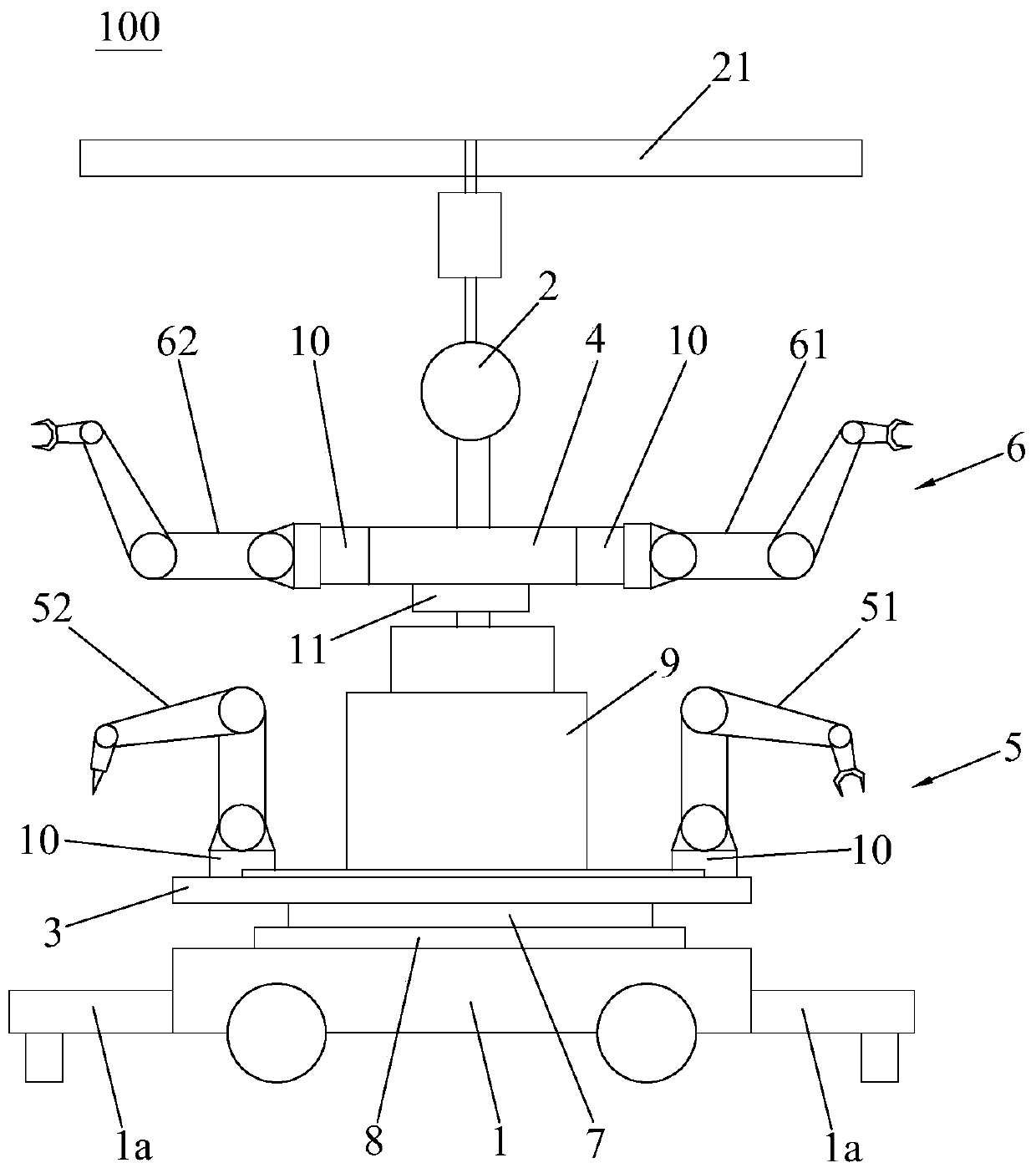

Embodiment 2

[0034] The structure of the building reinforcement construction robot 100 in this embodiment is basically the same as that of the construction reinforcement construction robot 100 in Embodiment 1, and the same points will not be described repeatedly. The difference is that this embodiment adds some functions on the basis of the first embodiment, specifically, the building reinforcement construction robot 100 also includes a second rotation drive mechanism 11 controlled by the monitoring system 2, the second The carrying platform 4 can rotate relative to the carrier 1 , and the rotation center axis coincides with the rotation center of the first carrying platform 3 . The second rotation driving mechanism 11 is arranged at the output end of the second lifting driving mechanism 9 and its output end is connected with the second carrying platform 4 to drive the second carrying platform 4 to rotate. The second rotation driving mechanism 11 can also be in the form of a motor-driven g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com