Composite double-layer ceramic flower pot blank machine

A composite double-layer, blank-making machine technology, applied in ceramic molding machines, manufacturing tools, auxiliary molding equipment, etc., can solve problems such as inability to make pottery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

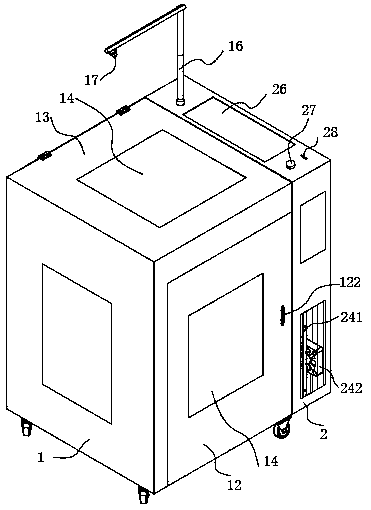

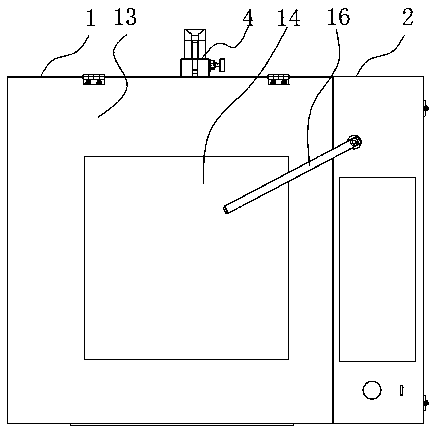

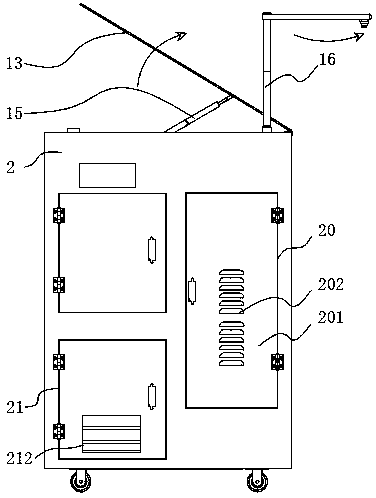

[0047] see Figure 1~Figure 8 , as an embodiment of the present invention, the composite double-layer ceramic flower pot blank making machine includes:

[0048] The sealing cabinet 1 is used to install the molding mechanism of the double-layer composite flower pot body. The inside of the sealing cabinet 1 is provided with a three-dimensional cabinet frame 11, and the front of the sealing cabinet 1 is provided with an openable and closing sealing door 12;

[0049] The control box 2 is arranged on the side of the sealed cabinet 1; the control box 2 is provided with an electrical control room 20 and a heating room 21, the heating room 21 is set on the side of the electrical control room 20, and the heating room 21 is located at the bottom of the control box 2;

[0050] The billet drawing mechanism 5 is arranged inside the sealed cabinet 1, and is used for forming and making the double-layer composite flowerpot blank;

[0051] The blanking controller includes a control circuit ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com