An error detection machine for linear low-density shuttle high-pressure winding of straw packaging tape

A linear low-density, packaging tape technology, applied in the field of error detection machines, can solve the problems of material processing loss of straw packaging tapes, affecting the effect of continuous supply adjustment, and unqualified finished products, avoiding vibration folding and pulling and cracking, and improving inspection. Incorrect self-regulation effect, effect of improving processing quality and progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

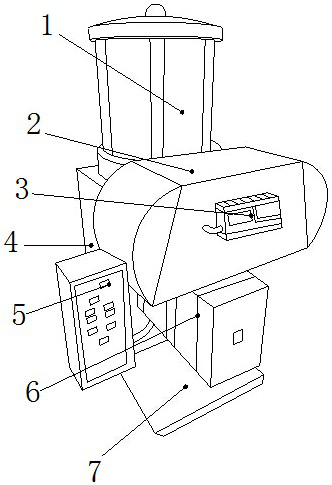

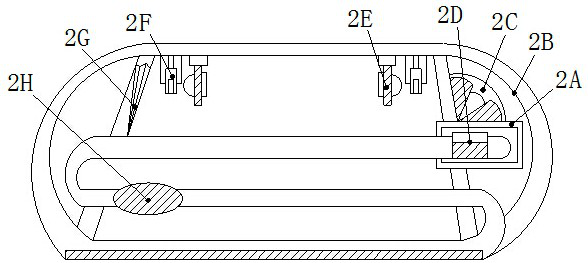

[0034] see Figure 1-Figure 7 , the present invention provides a linear low-density shuttle high-voltage winding error detection machine for straw packaging tape, the structure of which includes: a packaging tape reel 1, a shuttle correction chassis 2, a programmable controller 3, a transmission chassis 4, an electric control Box 5, motor slot seat 6, bottom support plate 7, the shuttle correction chassis 2 is nested in the front side of the transmission chassis 4 and penetrates each other, the programmable controller 3 is electrically connected with the shuttle correction chassis 2, the The packaging tape reel 1 is inserted and embedded on the top of the transmission case 4 and is on the same vertical plane, the electric control box 5 is installed on the lower left corner of the shuttle correction case 2, and the motor slot 6 is close to the slide Under the bottom surface of the shuttle correction cabinet 2, the bottom support plate 7 is arranged under the bottom surface of t...

Embodiment 2

[0041] see Figure 1-Figure 7 , the present invention provides a linear low-density shuttle high-pressure winding error detection machine for straw packaging tape, the other aspects are the same as in Embodiment 1, the difference is that:

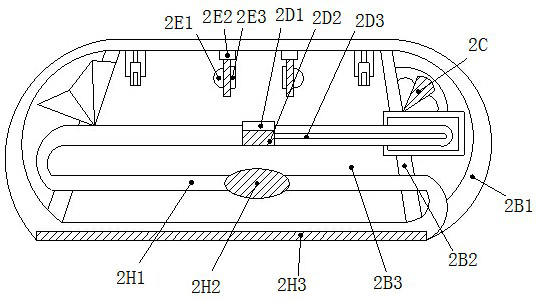

[0042] see image 3 The pole plate sliding frame 2E is composed of a pendulum semicircle groove 2E1, a suction cup slider 2E2, and a pole plate 2E3. The bottom of the slider 2E2 is on the same vertical line, and the suction cup slider 2E2 clips the pole plate 2E3 and the internal pins are connected to the circuit to form the effect of adjusting the resistance of the circuit caused by the suction cup adsorption and sliding, ensuring that the programmable controller 3 The programming books get feedback, and the real-time data of the straw packaging belt is also collected to facilitate the flexible program fine-tuning in the later stage.

[0043] see Image 6 The semicircular groove 2E1 of the pendulum is composed of a limit clamp 2E11, a c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com