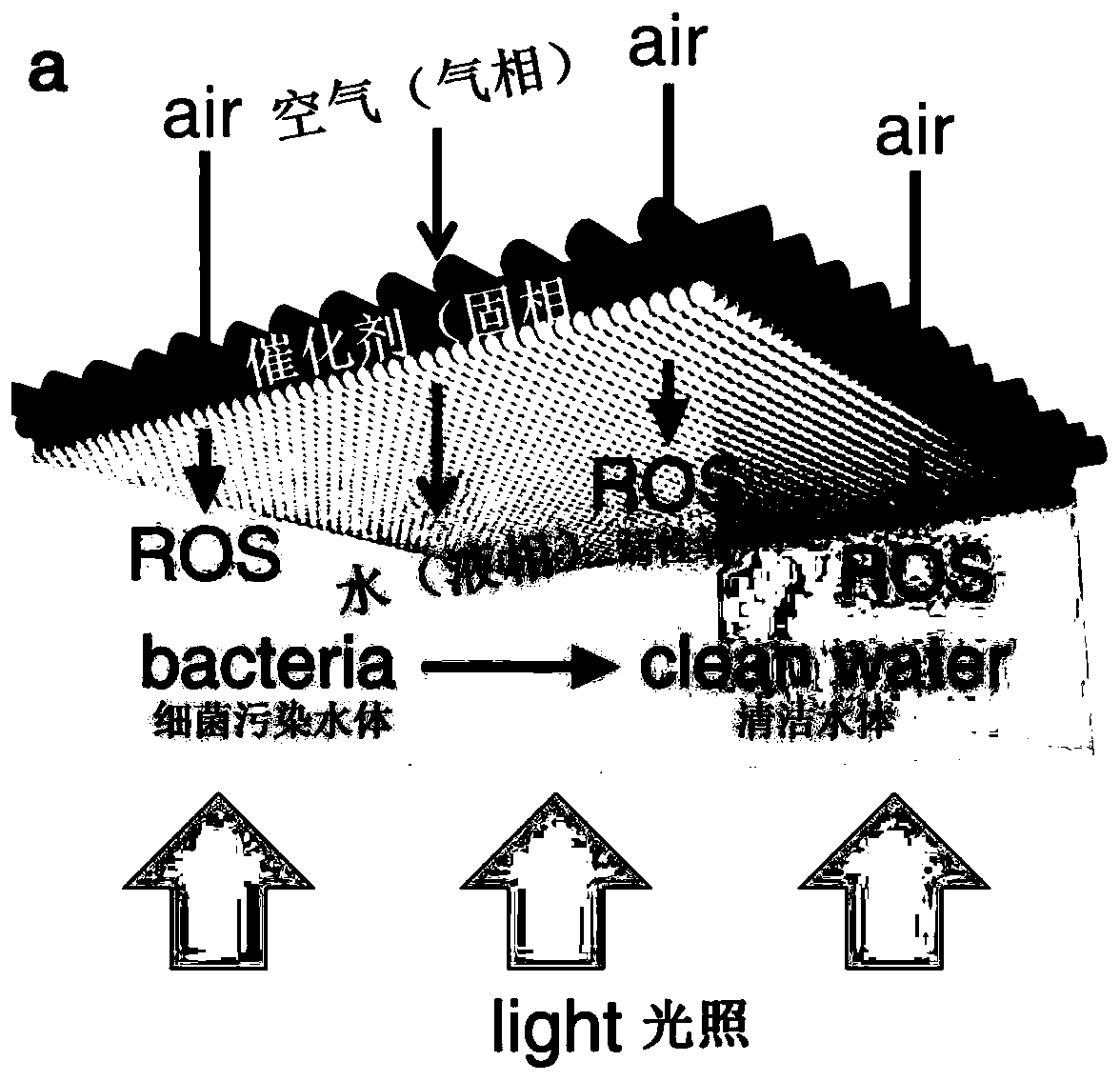

Photocatalytic gas-solid-liquid three-phase interface with adjustable wettability and preparation method and application thereof

A three-phase interface and catalytic gas technology, applied in chemical instruments and methods, light water/sewage treatment, oxidized water/sewage treatment, etc., can solve problems affecting three-phase interface contact and interface reaction, and improve the application effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A method for preparing a photocatalytic gas-solid-liquid three-phase interface with adjustable wettability, the steps of which are:

[0041] 1) Evenly disperse 100mg of photocatalyst titanium dioxide in 100mL of dispersion liquid H 2 O / EtOH(H 2 The volume ratio of O and EtOH is 1:10);

[0042] 2) Evenly drop the dispersed catalyst suspension on the 5×5cm 2 On the Toray carbon paper, the dropping rate is about 10mL per minute, and it is dried with infrared light;

[0043] 3) Transfer the above-mentioned dried sample to the reaction kettle, add 10 μL of (trifluoromethyl)trimethylsilane, under vacuum condition for 1-5min, and then react at 90-120°C for 30-60min;

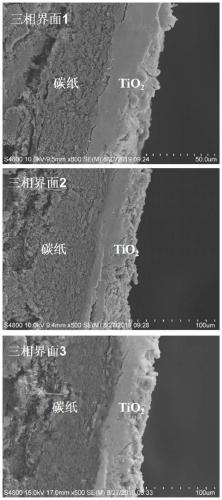

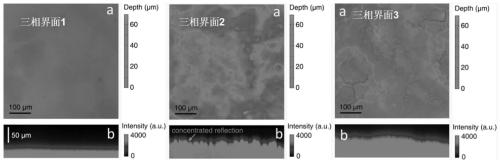

[0044] 4) After the reaction, the obtained carbon paper is put into a physical plasma processor, and the plasma is treated for 0.5h, 1h, and 2h, and a photocatalytic gas-solid-liquid three-phase interface with controllable wettability can be obtained. They are denoted as three-phase interface 1, three-phase i...

Embodiment 2

[0047] A method for preparing a photocatalytic gas-solid-liquid three-phase interface with adjustable wettability, the steps of which are:

[0048] 1) Evenly disperse 100mg of photocatalyst titanium dioxide in 100mL of dispersion liquid H 2 O / EtOH((H 2 The volume ratio of O and EtOH is 1:5);

[0049] 2) Evenly drop the dispersed catalyst suspension on the 5×5cm 2 On the Gaoshi Ruilian carbon paper, the dropping rate is about 1mL per minute, and it is dried with infrared light;

[0050] 3) Transfer the above-mentioned dried sample to the reaction kettle, add 10 μL of tridecafluorooctyltriethoxysilane, under vacuum condition for 1-5min, and then react at 90-120°C for 30-60min;

[0051] 4) After the reaction, the obtained carbon paper was put into a physical plasma processor, and after plasma treatment for 1 h, a photocatalytic gas-solid-liquid three-phase interface with controllable wettability was obtained, which was denoted as three-phase interface 4 , the hydrophobic agen...

Embodiment 3

[0054] A method for preparing a photocatalytic gas-solid-liquid three-phase interface with adjustable wettability, the steps of which are:

[0055] 1) Evenly disperse 100mg of photocatalyst titanium dioxide in 100mL of dispersion liquid H 2 O / EtOH(H 2 The volume ratio of O and EtOH is 1:10);

[0056] 2) Evenly drop the dispersed catalyst suspension on the 5×5cm 2 On the Gaoshi Ruilian carbon paper, the dripping rate is about 10mL per minute, and it is dried with infrared light;

[0057] 3) Transfer the above-mentioned dried sample to the reaction kettle, add 10 μL of heptadecafluorodecyltrimethoxysilane, under vacuum condition for 1-5min, and then react at 90-120°C for 30-60min;

[0058] 4) After the reaction, the obtained carbon paper is placed in a physical plasma processor, and after plasma treatment for 0.5 h, a photocatalytic gas-solid-liquid three-phase interface with adjustable wettability can be obtained, which is recorded as the three-phase interface 5. The hydrop...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com