Furnace lining gap repairing material and furnace lining gap repairing method

A technology for repairing materials and gaps. It is applied in the direction of lining repair, furnace, furnace components, etc. It can solve problems such as lack of elasticity, aggravate furnace lining damage, and furnace lining cracks, so as to maintain long-term stability and avoid secondary damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

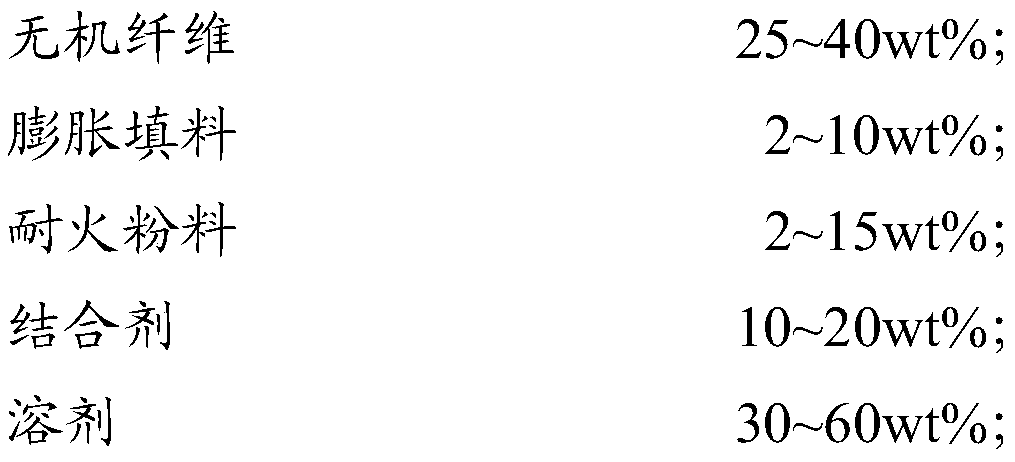

[0043] 1) Composition design:

[0044]

[0045] 2) Preparation of restoration materials:

[0046] According to the composition design in 1), each component is mixed evenly, and the furnace lining gap repair material can be obtained; the wet bulk density of the furnace lining gap repair material is 1250kg / m 3 , the bulk density after drying at room temperature (25°C) is 600kg / m 3 , compressive strength 0.5MPa, heating line shrinkage 0.1%, viscosity 100000MPa.S (25 ℃).

Embodiment 2

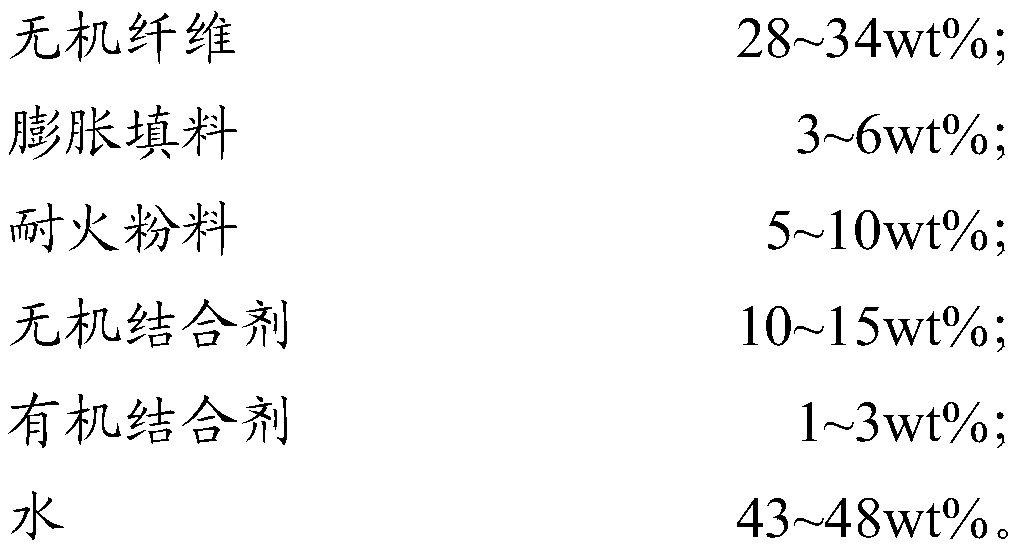

[0048] 1) Composition design:

[0049]

[0050] 2) Preparation of restoration materials:

[0051] Mix each component evenly according to the composition design in 1), and then the furnace lining gap repair material can be obtained; the wet bulk density of the furnace lining gap repair material is 1200kg / m 3 , the bulk density after drying at room temperature (25°C) is 580kg / m 3 , compressive strength 0.4MPa, heating line shrinkage 0.1%, viscosity 100000MPa.S (25 ℃).

Embodiment 3

[0053] 1) Composition design:

[0054]

[0055] 2) Preparation of restoration materials:

[0056] Mix each component evenly according to the composition design in 1), and then the furnace lining gap repair material can be obtained; the wet bulk density of the furnace lining gap repair material is 1150kg / m 3 , the bulk density after drying at room temperature (25°C) is 540kg / m 3 , compressive strength 0.3MPa, heating line shrinkage 0.2%, viscosity 100000MPa.S (25 ℃).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com