Energy absorption method based on hybrid cross-linked dynamic polymer

A technology of hybrid cross-linking and polymer, applied in the field of energy absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0374] In the preparation process of dynamic polymer foam materials, three methods of mechanical foaming, physical foaming and chemical foaming are mainly used to foam dynamic polymers.

[0375] Among them, the mechanical foaming method is to introduce a large amount of air or other gases into the emulsion, suspension or solution of the polymer with the help of strong stirring during the preparation of the dynamic polymer to make it a uniform foam, and then through physical Or chemical changes make it shape and become a foam material. In order to shorten the molding cycle, air can be introduced and emulsifiers or surfactants can be added.

[0376] Wherein, the physical foaming method is to use physical principles to realize the foaming of the polymer during the preparation of the dynamic polymer, which includes but not limited to the following methods: (1) inert gas foaming method, that is, after adding Press the inert gas into the molten polymer or pasty material under high ...

Embodiment 1

[0396] Using 3-acrylamido dopamine as raw material and AIBN as initiator, acrylamide-dopamine copolymer was prepared by free radical polymerization with N,N-dimethylacrylamide.

[0397] Weigh a certain amount of N,N-dimethylacrylamide, dissolve it in deionized water to prepare a 1mol / L solution, add 1mol% of cross-linking agent N,N'-methylenebis Acrylamide, 0.6 mol% initiator potassium persulfate, stirred and mixed evenly, left to stand for 1 hour to remove air bubbles, placed in a constant temperature water bath at 60°C for 4 hours to obtain a polyacrylamide gel. Weigh a certain amount of acrylamide-dopamine copolymer and dissolve it in deionized water to form a 0.5mol / L solution, then add an appropriate amount of sodium borate, dropwise add a small amount of NaOH solution and mix evenly, after reacting for 2 hours, add 0.05mol sodium alginate, And the previously prepared polyacrylamide gel was swollen in the mixed solution, and 0.05mol / L CaCl was added dropwise 2 Solution, ...

Embodiment 2

[0399]

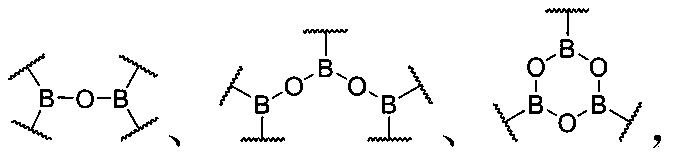

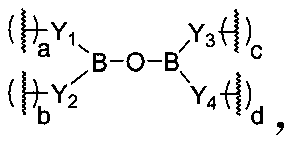

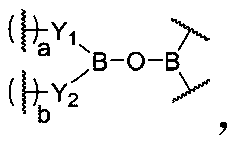

[0400] Using acrylamide and 3-acrylamide phenylboronic acid as raw materials and AIBN as an initiator, acrylamide-phenylboronic acid copolymer (a) is obtained through RAFT radical polymerization.

[0401] Take a certain amount of sodium alginate dissolved in deionized water to prepare a 0.1mol / L solution, take 50ml and add it to a dry and clean three-necked flask, add 5ml Ca-EDTA / GDL mixed solution dropwise, and then add 15g acrylamide-benzene Boric acid copolymer (a), 8g polyvinyl alcohol, 200ml deionized water, heated to 50°C and stirred for 30min to dissolve, then added 2ml of triethylamine, continued to stir and react at 50°C for 2h to form the first network. Then add 10g polyacrylic acid, after stirring and dissolving, add 0.84g aziridine cross-linking agent (b) to continue the reaction for 1h, after the reaction ends, a hybrid cross-linked multi-network hydrogel is obtained. In this example, the prepared polymer hydrogel can be used as a composite packaging m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com