Light-emitting pervious concrete road based on recycled aggregate and construction method thereof

A technology of permeable concrete and recycled aggregate, applied in the direction of roads, roads, coagulation pavement paved on site, etc., can solve problems such as lack of exploration and engineering application examples, and achieve improved light absorption efficiency, good insulation and water resistance, and improved The effect of luminous properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

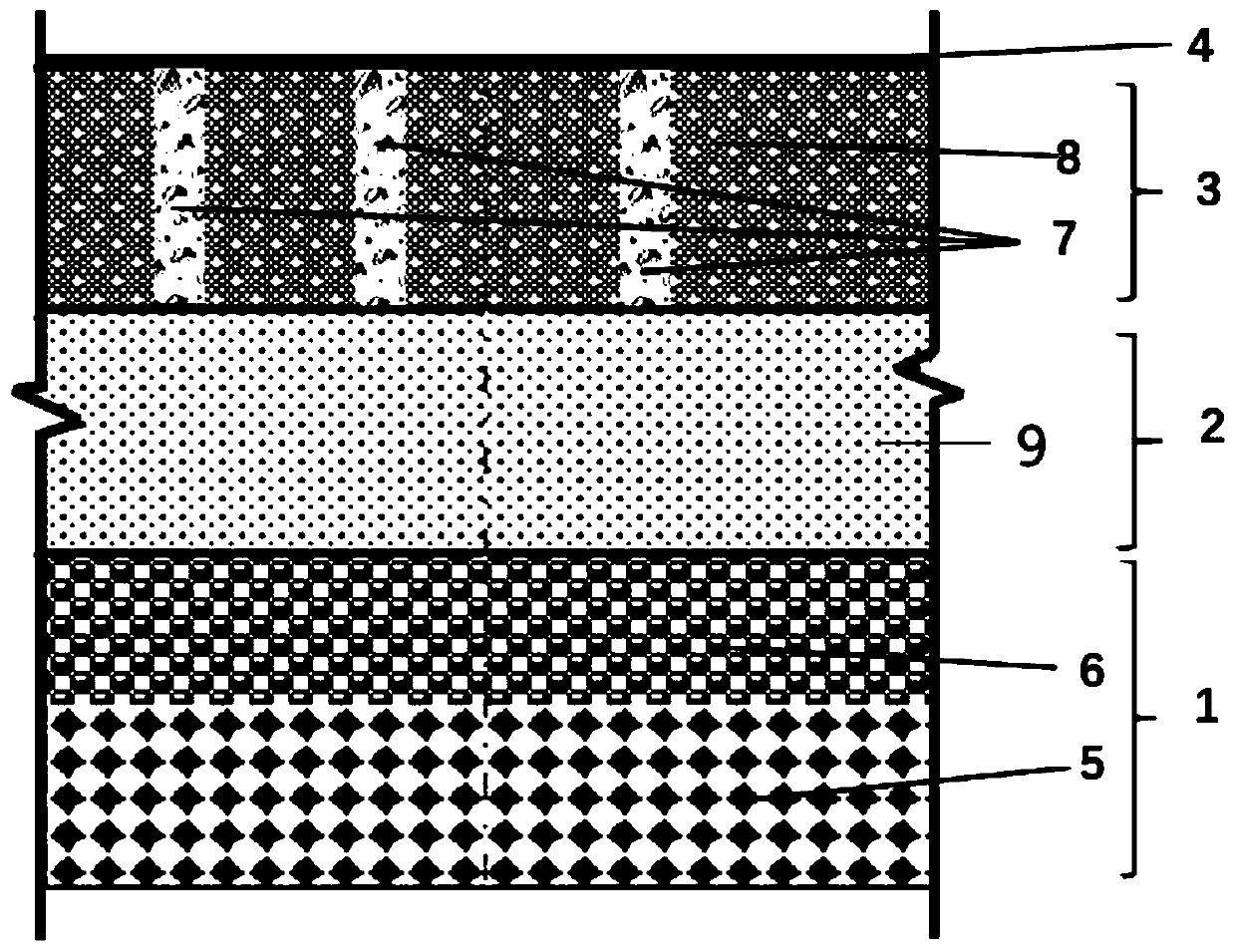

[0050] Such as figure 1 As shown, a luminous permeable concrete road based on recycled aggregates, the road includes a permeable cushion 1, a permeable base layer 2 and a luminous permeable surface layer 3 laid sequentially from bottom to top, and the surface of the luminous permeable surface layer 3 is painted with Luminous water-permeable surface layer sealant 4; water-permeable cushion layer 1 includes pressed ceramsite 5 and low-quality recycled aggregate 6 laid sequentially from bottom to top; water-permeable base layer 2 is the first high-quality recycled aggregate permeable concrete 9; luminous water-permeable surface Layer 3 includes luminous permeable concrete 7 and the second high-quality recycled aggregate permeable concrete 8; the luminous permeable surface layer sealant 4 adopts double propylene polyurethane sealant. Among them, the laying thickness of the permeable cushion layer 1 is 60mm; the laying thickness of the permeable base layer 2 is 80mm; the laying thi...

Embodiment 2

[0066] Except that the laying thickness of the permeable cushion layer 1 is 40mm; the laying thickness of the permeable base layer 2 is 50mm; the laying thickness of the luminous permeable surface layer 3 is 50mm; The mass ratio of aggregate to cementitious material is 85:15; the second highest quality recycled aggregate permeable concrete 8 is made by mixing the second highest quality recycled aggregate and cementitious material slurry, and the second highest quality recycled aggregate The mass ratio to the gelling material is 95:5. The water absorption rate of low-quality recycled aggregate is 4.0%, and the bulk density is 1100Kg / m 3 , the apparent density is 2.45g / cm 3 , the crushing value is 14%, the needle flake particle content is 4%; the water absorption rate of the first high-quality recycled aggregate is 2%, and the bulk density is 1275Kg / m 3 , the apparent density is 2.65g / cm 3 , the crushing value is 8%, the content of needle flake particles is 0.5%; the water ab...

Embodiment 3

[0068] In addition to the laying thickness of the permeable cushion 1 is 80mm; the laying thickness of the permeable base layer 2 is 76mm; the laying thickness of the luminous permeable surface layer 3 is 63mm; the thickness of the luminous permeable surface sealer 4 is 3mm, the first high-quality regeneration The mass ratio of aggregate to cementitious material is 95:5; the second high-quality recycled aggregate permeable concrete 8 is made by mixing and stirring the second-highest-quality recycled aggregate and cementitious material slurry, and the second-highest-quality recycled aggregate The mass ratio to the gelling material is 85:15. The water absorption rate of low-quality recycled aggregate is 5.5%, and the bulk density is 1300Kg / m 3 , the apparent density is 2.65g / cm 3 , the crushing value is 18%, the content of needle flake particles is 6%; the water absorption rate of the first high-quality recycled aggregate is 4%, and the bulk density is 1400Kg / m 3 , the apparen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com