Single-layer aluminum alloy latticed shell box type modular assembly node and construction process thereof

A technology of aluminum alloy mesh and construction technology, which is applied in the direction of architecture and building construction, can solve the problems of the span limitation of reticulated shell structures, and achieve the effects of convenient and fast assembly, reduced workload, and increased span

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

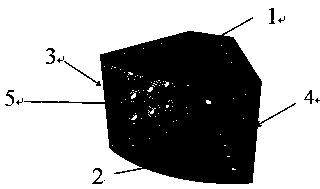

[0039] (1) For rapid construction, the present invention designs modular aluminum alloy assembly nodes and their construction techniques. The upper and lower circular cover plates in the existing traditional plate-type joints are canceled, and the connecting joints are designed as several integral "modular joints". This modular joint has a high degree of "universality". The modular node consists of 6 pentahedron semi-closed box structures and a reinforcing ring 9 in the middle as a whole (excluding the I-shaped beam 6, the six I-shaped beams are connected structures, and every six beams intersect at a node , that is, each node connects six beams), the shape of the pentahedron semi-closed box structure is a pentahedron semi-closed box structure, and the plane projection is fan-shaped (see figure 1 ). It is formed by machining in the factory, and it can also be cast into an integrated cast aluminum node by mold casting.

[0040] First, three I-shaped beams 6 are connected with...

Embodiment 2

[0045] Different from Example 1, as Figure 10 As shown, four hexagonal "module units 2" are connected to form a large triangular "expanded module unit 2" through channel beams. Also hoist an "expanded modular unit 2" to the central area of the reticulated shell structure, expand along the three sides in the direction of the arrow in the figure, and continuously form an adjustment area during the assembly process. The triangular boundary condition of the reticulated shell can be satisfied by extending to the boundary. Install corresponding I-shaped beams and nodes in the adjustment area to complete the adjustment of the overall stiffness.

Embodiment 3

[0047] Following a similar approach, such as Figure 11 As shown, three hexagonal "module units 2" are connected to the webs of the outer channel beams to form a parallelogram "expanded module unit 3". Expanding in the direction of the arrow in the figure can satisfy the parallelogram or rhombus boundary conditions of the reticulated shell.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com