Coal seam floor limestone confined aquifer grouting reinforcement transformation method

A technology for confined aquifers and coal seam floors, applied in earthwork drilling, shaft equipment, wellbore lining, etc., can solve problems such as water damage threats, and achieve the effects of improved compressive strength and high-quality and efficient mining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the above purpose, features and advantages of the present application more obvious and understandable, the present application will be further described in detail below in conjunction with the accompanying drawings and specific implementation methods.

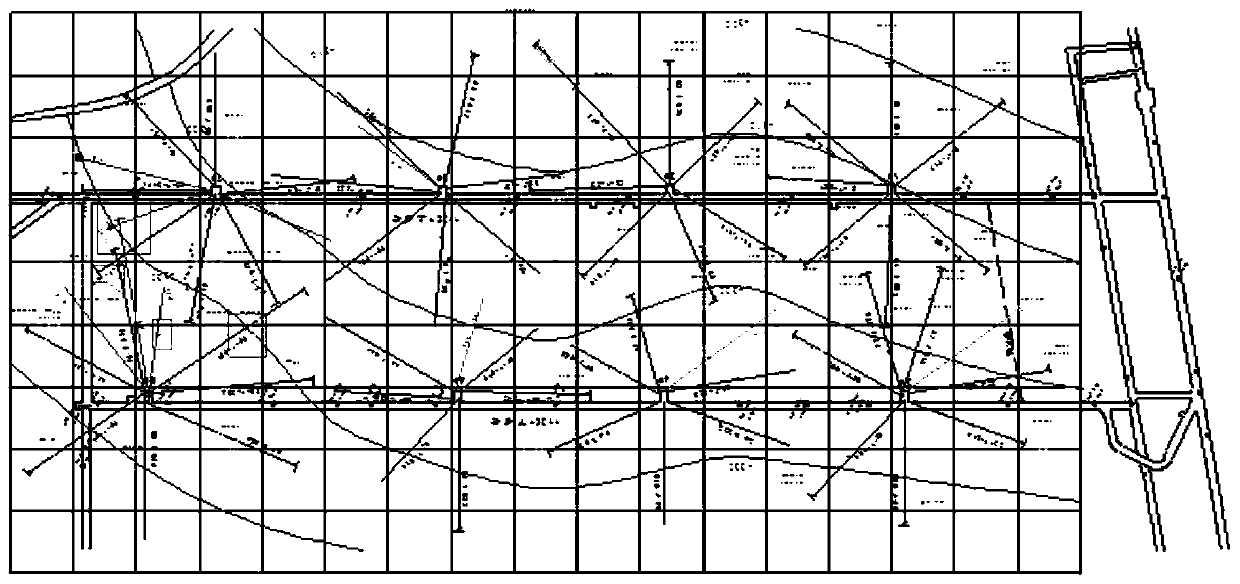

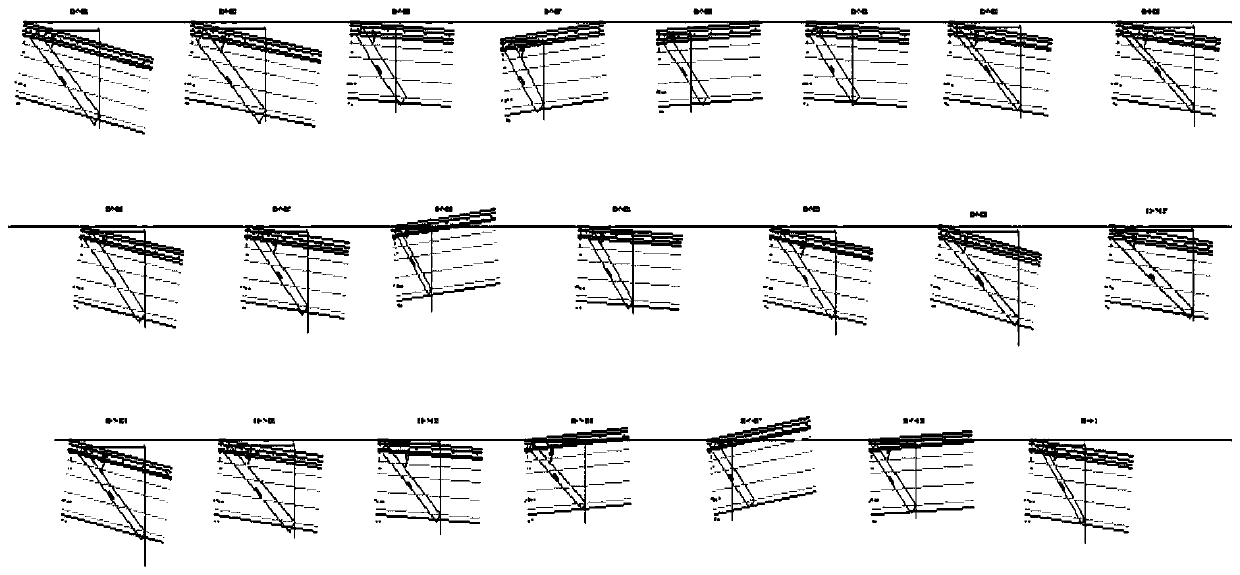

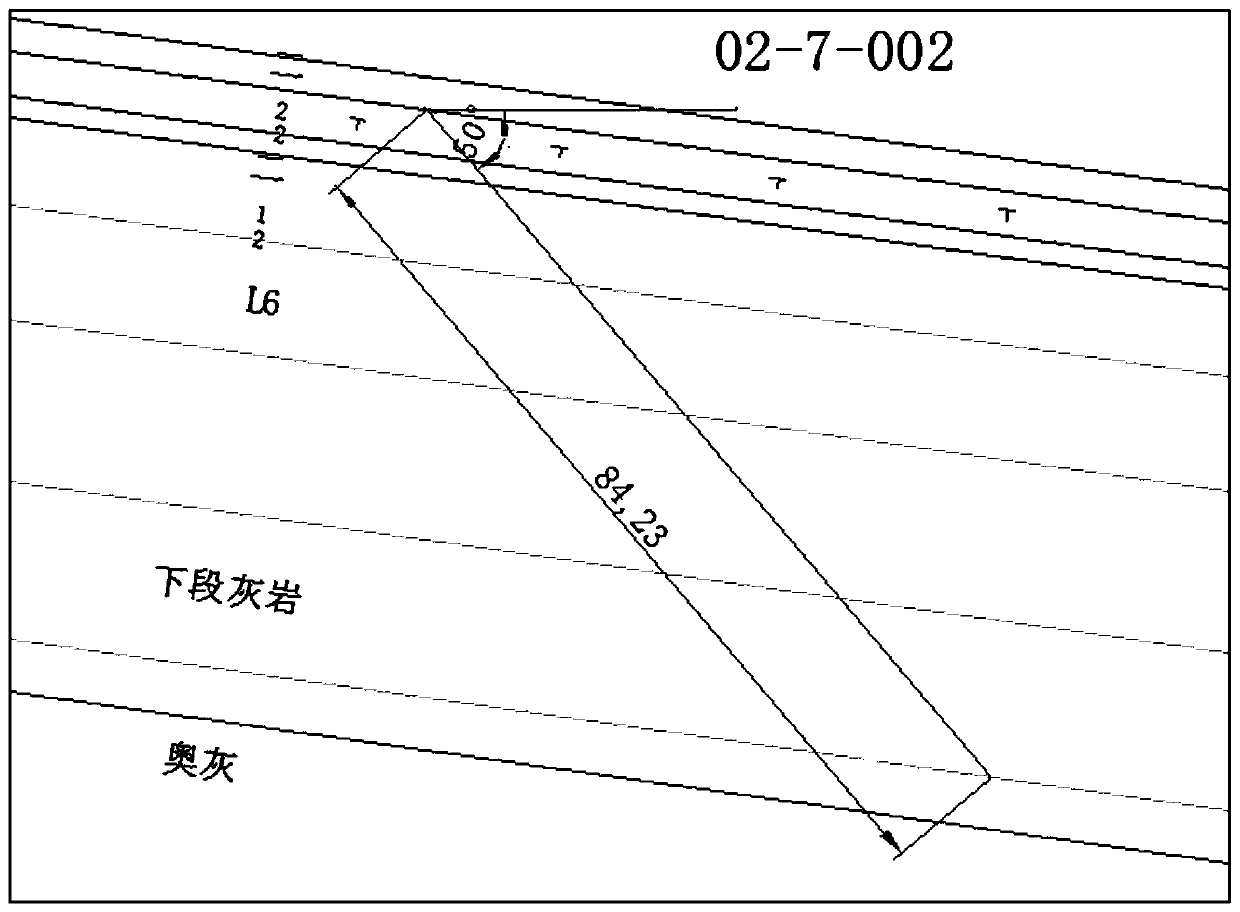

[0034] my country's coal seam floor limestone confined aquifer water disaster control has mainly gone through the following six stages: (1) surface pumping test; (2) underground water discharge test; (3) underground drainage and pressure reduction; (4) surface grouting reinforcement; 5) Downhole grouting reinforcement; (6) Surface downhole combined grouting reinforcement. The grouting material used gradually transitions from cement to clay cement grouting material. The purpose of grouting has also gone through the process from grouting to strengthen the aquifer of the coal seam floor to grouting to transform the confined aquifer of the floor. The grouting reinforcement reconstruction method for the limes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com