Large-capacity buffer tank with noise reduction and vibration reduction functions

A large-volume, buffer tank technology, applied in the direction of variable volume pump components, liquid variable volume machinery, machines/engines, etc. Reduce uneven impact, avoid swing, and meet the effect of stable operation of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In the following, the ultra-low temperature pipeline steel and its manufacturing method according to the present invention will be further explained and described in conjunction with the accompanying drawings and specific examples. However, such explanations and descriptions do not constitute undue limitations on the technical solution of the present invention.

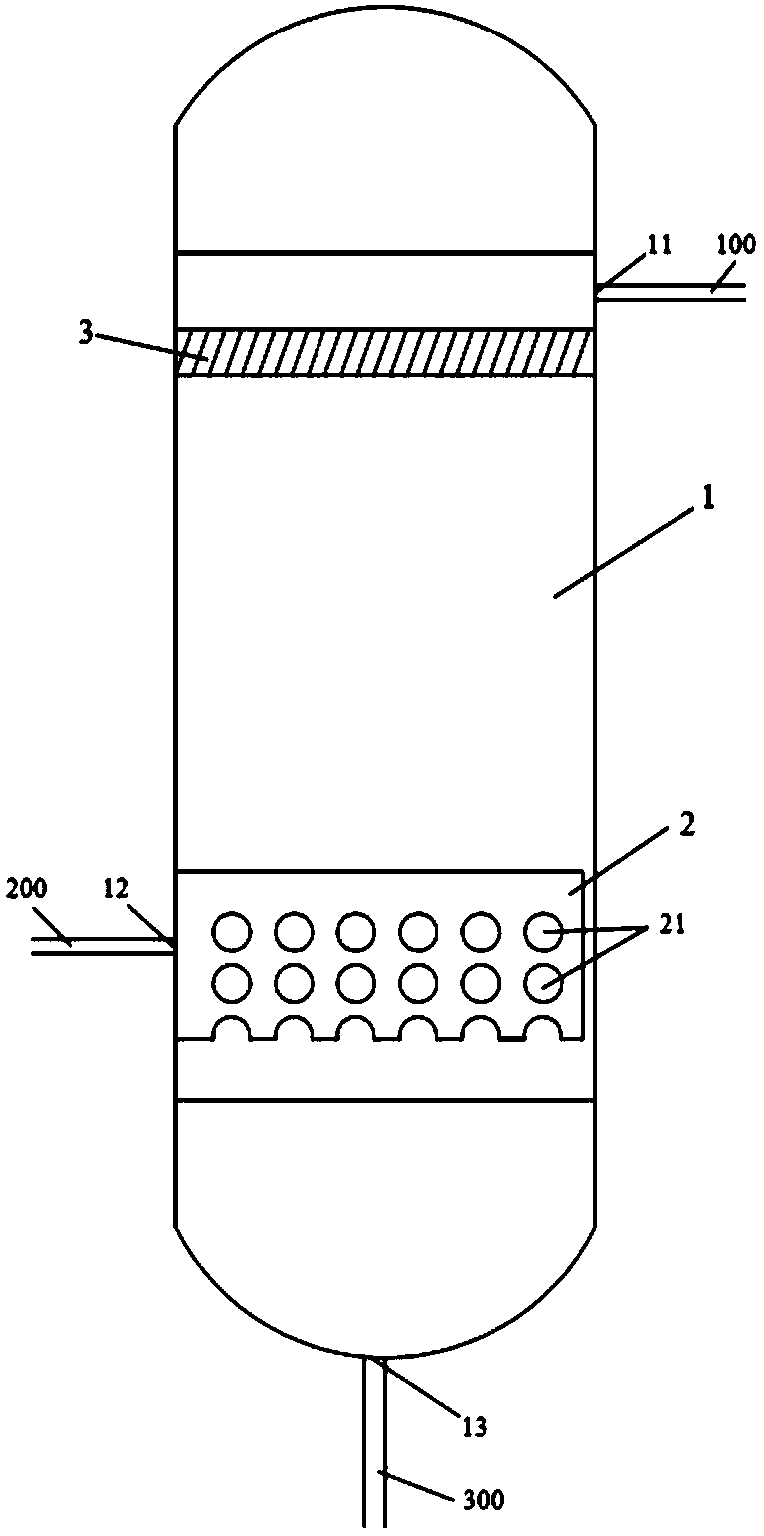

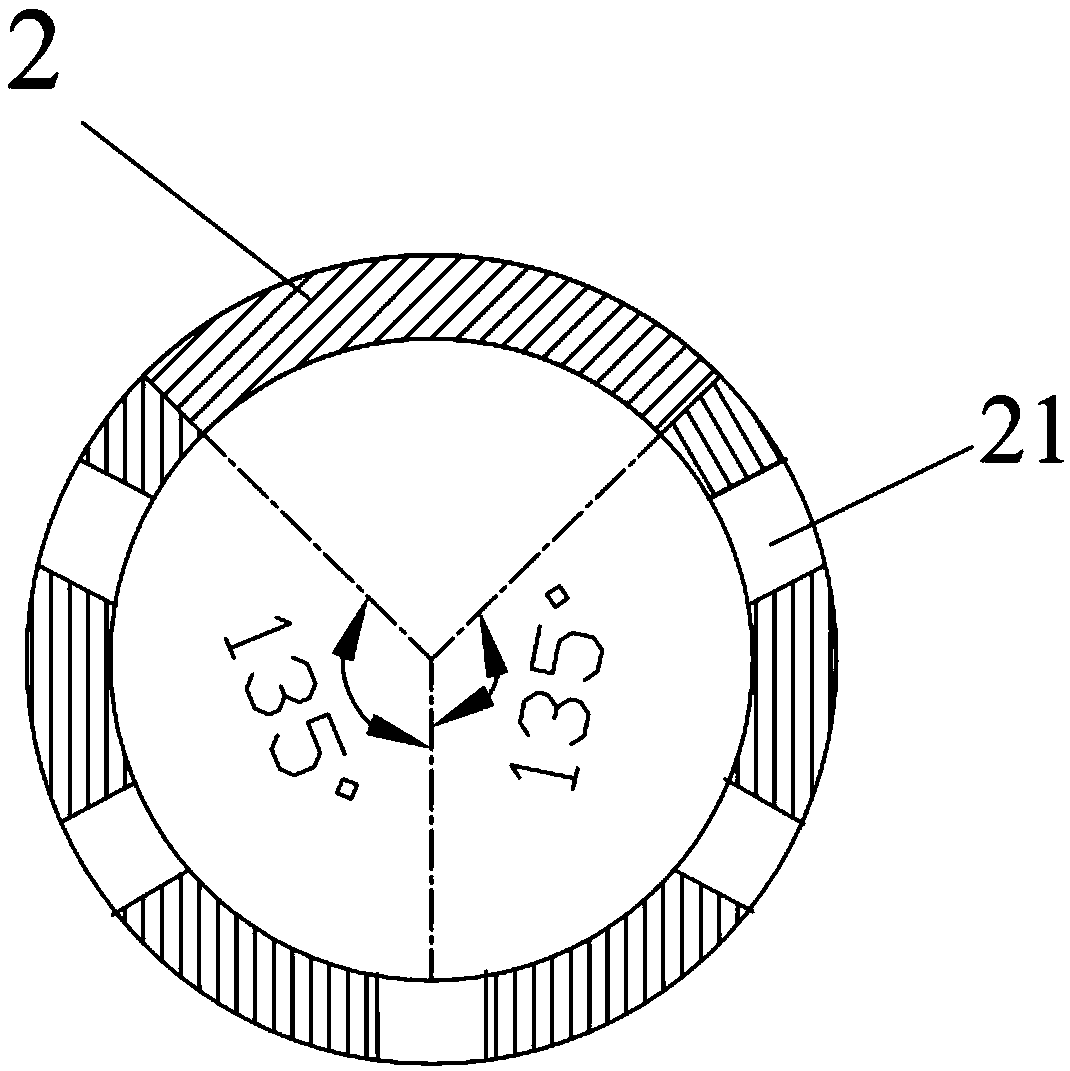

[0016] see Figure 1-Figure 2 , a kind of large-volume buffer tank with sound-absorbing and vibration-reducing function provided by the present invention comprises, a tank body 1, an air outlet 11 and an air inlet 12 are respectively set up and down on it, and a sewage outlet 13 is opened at the bottom; 11. The air inlet 12 and the sewage outlet 13 respectively correspond to the air outlet pipe 100, the air inlet pipe 200, and the sewage pipe 300; the gas distributor 2 is a horizontal columnar pipe structure with one end open, and is arranged in the tank body 1; the gas The open end of the distributor 2 communi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com