Straightness measurement interferometer system without nonlinear errors and measurement method

A non-linear error and measurement method technology, applied in measurement devices, instruments, optical devices, etc., can solve the limitation of straightness error detection accuracy, nonlinear error, the error can reach more than ten nanometers or even dozens of nanometers and other problems to achieve the effect of eliminating nonlinear errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

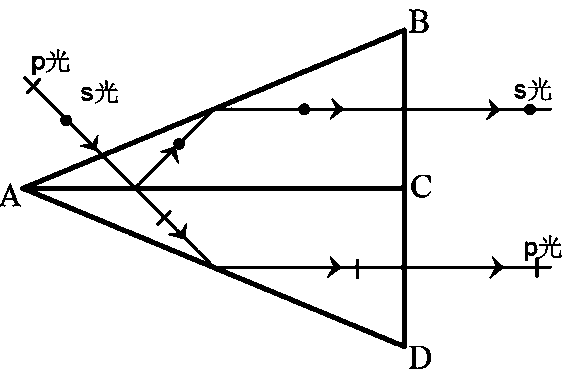

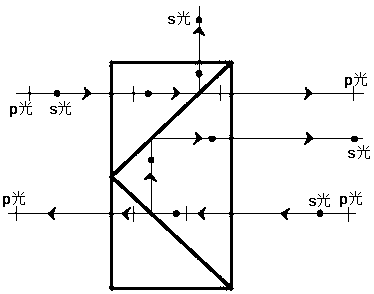

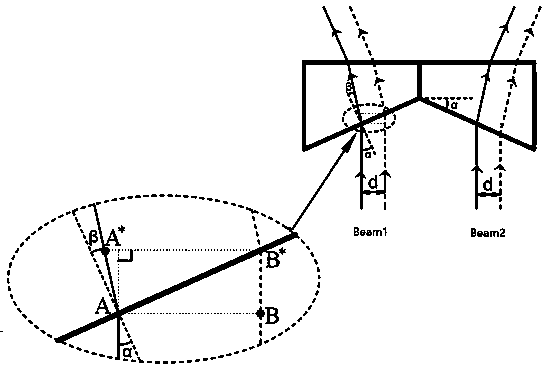

[0045] The invention provides a straightness measurement interferometer system without nonlinear error, see Figure 4 , which is a heterodyne light source system, which includes a frequency-stabilized laser 1, a dichroic prism 2, a first-stage acousto-optic modulator 3 and a second-stage acousto-optic modulator 6, a first light-shielding element 4 and a second light-shielding element 7. The first rectangular prism 5, the second rectangular prism 8, and the third rectangular prism 9; refer to Figure 5 , which is a straightness measurement interferometer system, which includes: a Koesters prism 20, a half-wave plate 21, a combined dichroic prism 22, a quarter-wave plate 24, a rectangular prism 23, a combined wedge prism 25, Combined wedge reflector 26 and two-stage photoelectric receiver one 27, two-stage photoelectric receiver two 28;

[0046] Optical device Koesters prism among the present invention, it is made up of the triangular prism of size symmetry, and the right-angle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com