Hydraulic high-pressure particle jet plug drilling test device

A test device and particle technology, applied in the field of oil drilling and production, can solve the problems of stuck drilling accident, drill bit milling casing, casing damage, etc., and achieve the effects of reliable dynamic sealing, optimized construction parameters, and adjustable WOB.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with accompanying drawing:

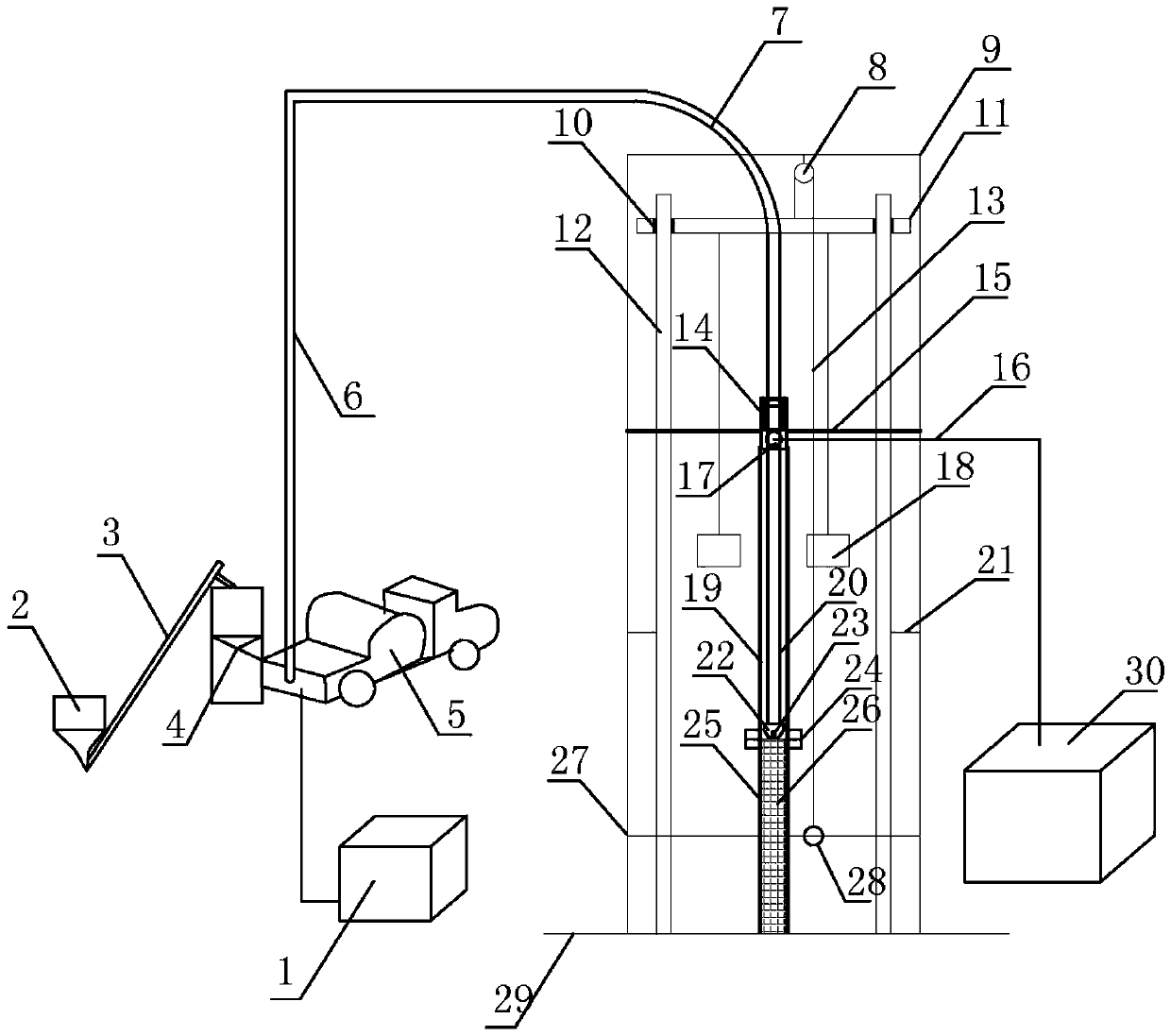

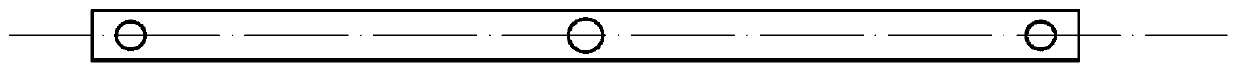

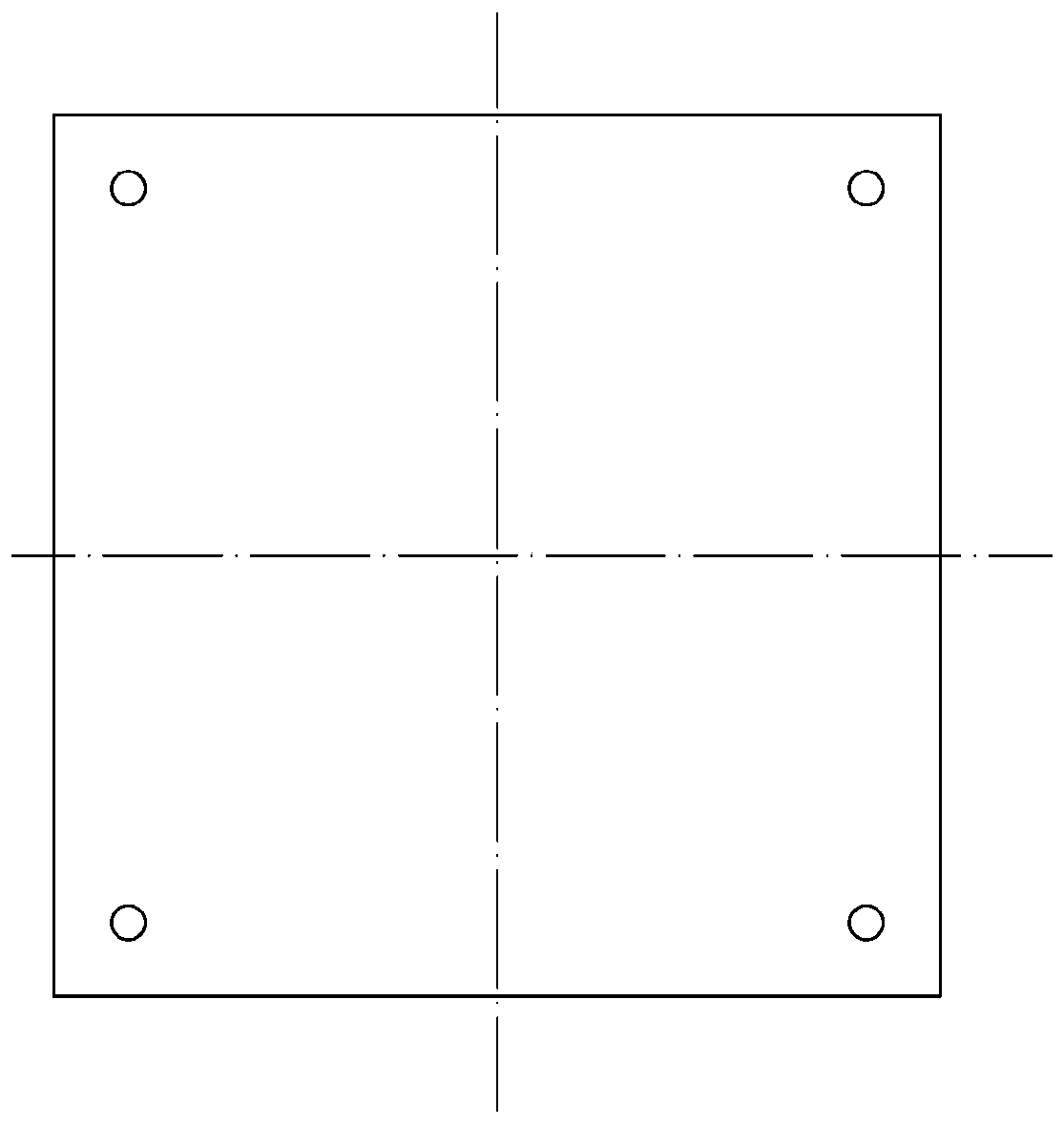

[0016] like Figure 1~3As shown, the hydraulic high-pressure particle jet drilling plug test device of the present invention includes a storage tank 1, a sand mixing cylinder 2, a conveyor 3, a material receiving cylinder 4, a cement truck 5, a high-pressure pipe 6, a high-pressure elbow 7, and a pulley 8. Skid mounting frame 9, sliding sleeve 10, moving beam 11, vertical rail 12, steel wire rope 13, sliding seal assembly 14, centralizing rod 15, return pipeline 16, return liquid port 17, counterweight 18, glass Upper cylinder 19, oil pipe 20, middle beam 21, nozzle 22, nozzle 23, flange plate 24, glass lower cylinder 25, cement plug 26, bottom beam 27, hinge 28, base 29, recovery tank 30. The storage tank 1 is arranged on the ground for storing circulating fluid and supplying liquid for the cement truck 5. The sand mixing tank 2 is arranged at the front of the cement truc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com