Metal nano material preparation device and method

A preparation device and metal nanotechnology, applied in chemical instruments and methods, mixers with rotating stirring devices, transportation and packaging, etc., can solve the problems of uneven particle size of nanomaterials, inability to remove impurities, easy to stir unevenly, etc. , to achieve a good mixing effect, ensure the initial treatment effect, and improve the mixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

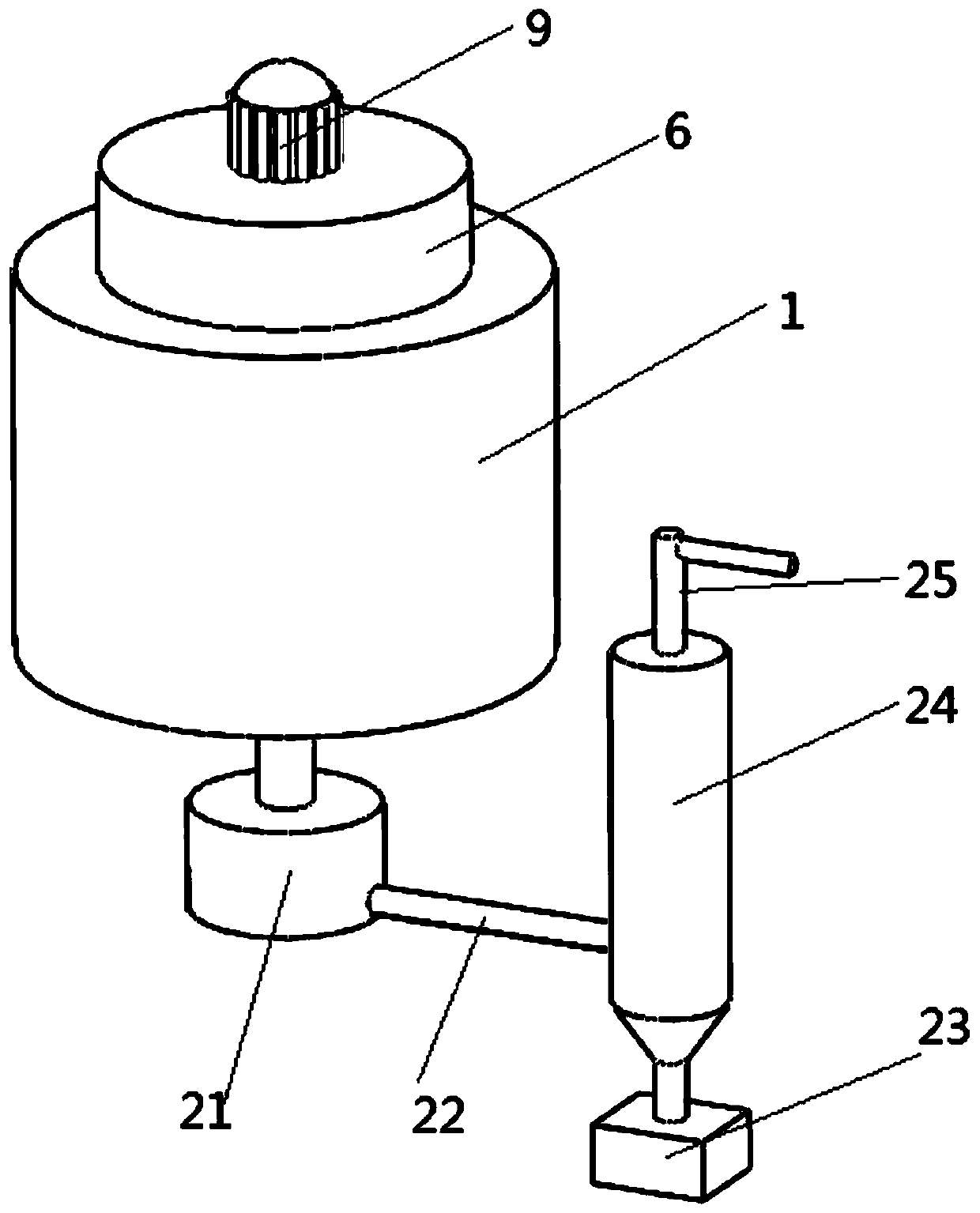

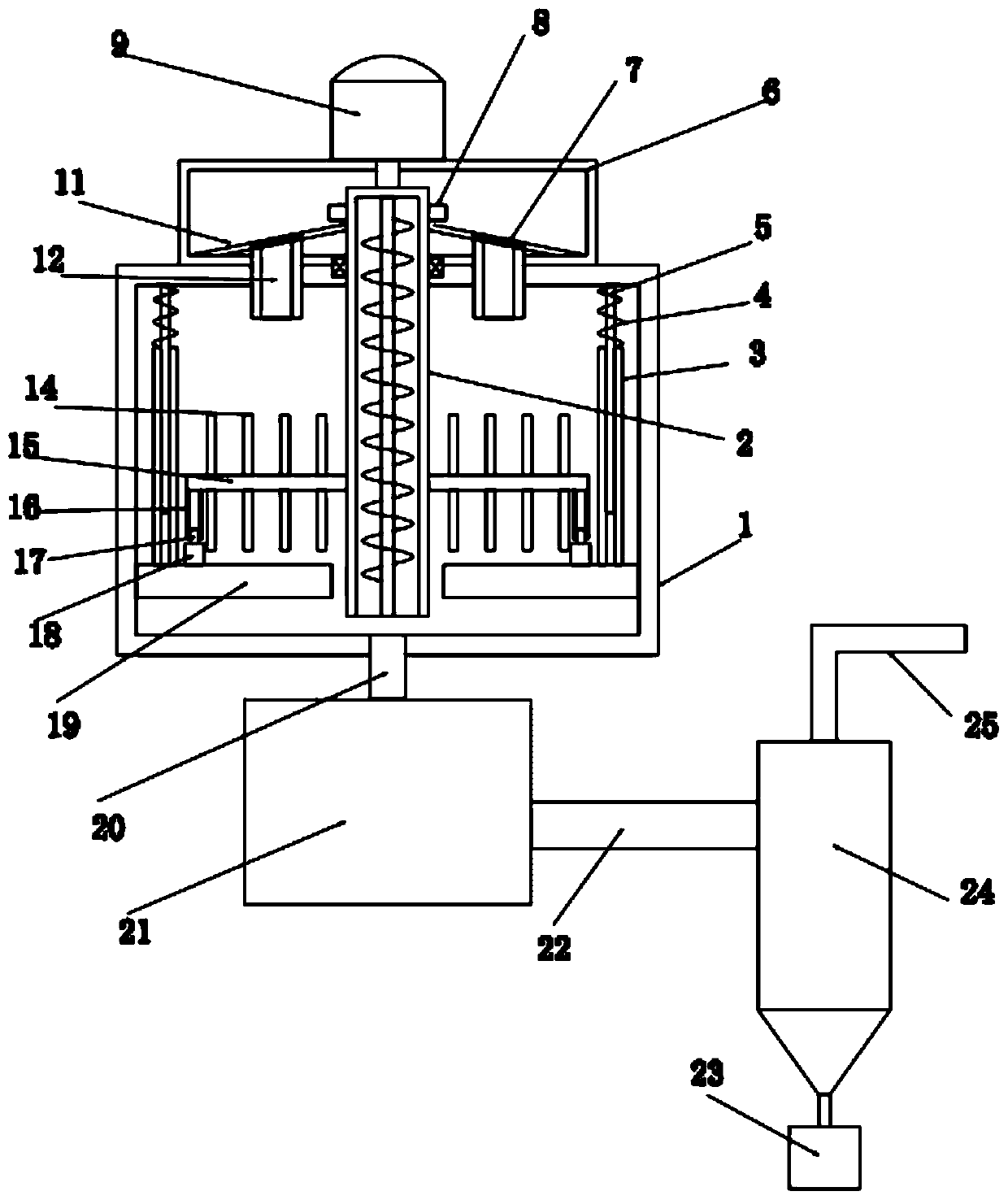

[0035] see Figure 1-4 , in an embodiment of the present invention, a metal nanomaterial preparation device includes a stirring box 1 for pretreatment of processing raw materials, and the discharge end of the stirring box 1 is connected through a discharge pipe 20 for mixing solid and liquid Drying box 21 for fast drying of materials, the discharge end on the right side of the drying box 21 is connected to the cyclone separator 24 for separating the materials in the solid-liquid mixture through the communication pipe 22, and the outlet at the lower end of the cyclone separator 24 A collection box 23 for collecting solid materials is provided at the feed opening, and an exhaust pipe 25 is provided at the upper end of the cyclone separator 24;

[0036] The upper end of the mixing box 1 is provided with a feeding end and a water adding end;

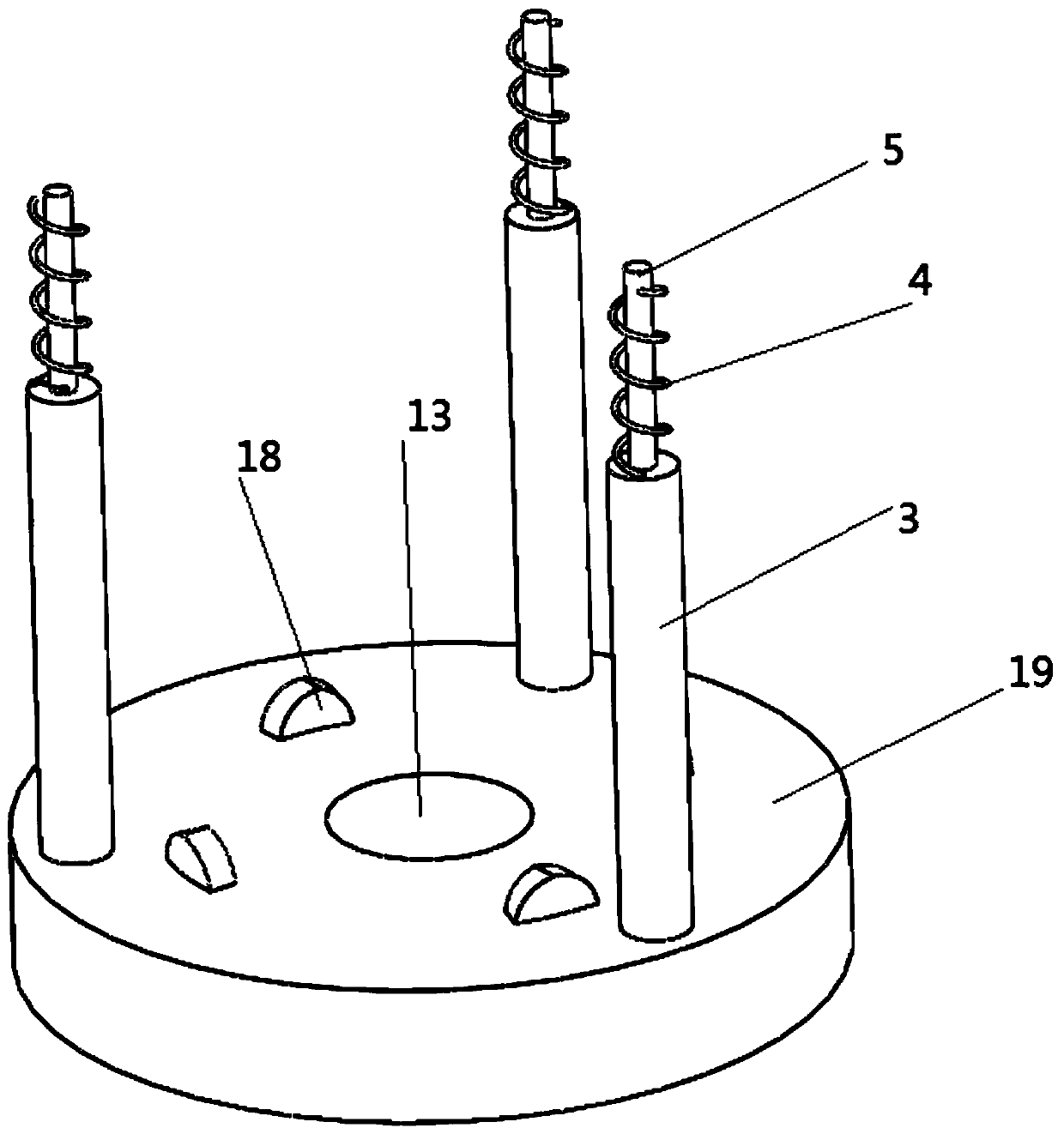

[0037] The stirring box 1 is provided with processing components for fully stirring and screening materials;

[0038] Described processin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com